We recently sat down with Bill Wilson, founder of Wilson Combat, about his company’s history with the AR platform. While perhaps best known for handguns, Wilson Combat is also known for its high-quality, duty-grade rifles in a wide variety of calibers.

Q: Bill, thanks for taking the time to chat. I know your early history was in jewelry and watchmaking…can you briefly walk us through that history and how that led to the creation of Wilson Combat?

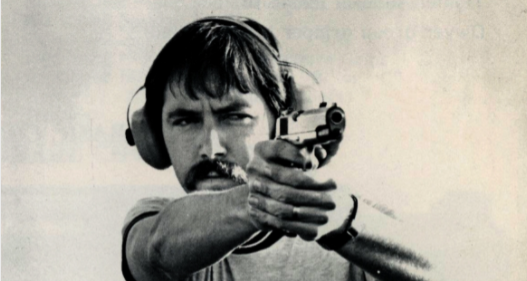

Bill Wilson, Wilson Combat – Like you said, I came from a watch and jewelry family, and back in the early 70s, to appease my dad, who wanted me to take over the jewelry store, I went to a watch and jewelry-making school. I brokered a deal with him that if he let me do that, he would let me open a small gun shop adjacent to the jewelry store. He fell for that deal, and I did my “tour of duty” at the watch and jewelry-making school. Very soon, I had a retail gun shop going, and when I got out of school, I found myself spending all of my time inside that gun shop, with very little time spent making watches or jewelry (laughs). That little shop morphed into something else. I was a revolver shooter, and I found myself doing action jobs on revolvers, putting Bo-Mar ribs on them, and things like that. That was how I got started in the custom gun business.

Q: At what point did you start making accessories for the AR platform.

Bill Wilson, Wilson Combat – Well, time flies when you’re having fun, and I cannot give you a specific year, but in the early 90s, we initially started doing a few AR-related things. We got really heavy into AR accessories by around 2002. Around that time, we started building out our machine shop capabilities. Some of the first things we did were AR receivers, handguards, and a few other things.

Q: You’re well known for carefully building 1911s. How does that translate over into the world of AR-15s and AR parts and accessories?

Bill Wilson, Wilson Combat – I look at what we do for ARs to be very similar to our approach to handguns. You have to keep tight tolerances on functional areas, especially bolt carriers and bolts…it compares to the kind of tolerances on handguns we make at Wilson Combat.

When we build an AR, we put the same care into what we do with our handguns. We start with a ‘kit,’ and we have people here who have the specific job of building that kit, whether for a handgun or a rifle. It’s different people, but it’s the same process. When it goes to a bench for a build, all of the parts are right there for that specific build. We don’t do mass assembly unless it’s a big distributor order or something like that.

Earlier this year and late last year, when things were very crazy, we got several big orders from distributors, and we’d build rifles in lots of 100 or so. In that case, it was more of an assembly line, but only because each gun was the same. Most of what we do is similar to our handguns. Someone contacts us and says he wants this barrel, that handguard, this finish, trigger, etc. It becomes a unique gun for each specific customer.

Q: In recent months, we’ve seen a lot of quality control issues in the industry. Can you speak to your company’s commitment to putting out quality firearms and accessories?

Bill Wilson, Wilson Combat – Quality is what brought us to the dance originally. At Wilson Combat, we don’t have a tolerance for quality issues. We’re really detailed in our inspection department. I know that might sound like something that other companies say, but in our case, I can assure you that it’s something we pay an incredible amount of attention to. Our inspection department has around ten people in it…we have all kinds of CMM equipment, and we try to make sure everything is right.

When it’s time to do the build process, Normally, one guy will build the upper, and another will build the lower. Both inspect at that time. Then the parts will go together. There will then be an inspection at that point. From there, the people that do the test-fire inspect it again. So, it basically gets three inspections.

I know some companies are content to shoot a round or three through the guns as far as test fire. We do around 30 rounds through our ARs and 60 rounds on a handgun for our test-fire protocol. We’re focusing on checking things on what I call ‘both ends of the cycle.’ What does it do on the last shot, and what does it do feeding the first round out of a magazine? If it works at the start and it works at the end, you usually don’t have any functioning issues in the middle of a magazine…

Customer service is another thing I’d like to touch on that makes Wilson Combat special. Aside from our focus on quality, customer service is our other strong point. I think you’d be hard-pressed to find much negative on the internet or anywhere about that kind of issue because we like to take care of our customers…We bend over backwards to get customers taken care of.

Q: Your rifles are in service in self-defense/LE roles and certainly meet the criteria for duty grade. Can you speak to what goes into building an AR you can depend on from your point of view?

Bill Wilson, Wilson Combat – I think that when it comes to building a hard-use AR that is going to be reliable no matter what, it starts with making sure the components you choose are of top quality. There are people out there that still make bolts out of 8620…real ‘el cheapo’ stuff. There’s no substitute for using top-quality materials held to high-end tolerances and ensuring you’re verifying the certs on your materials, your heat treat certs, and that kind of stuff. The components have to be consistent.

Barrels are also a key component I want to mention. We make all of our barrels in-house, and we produce about 4,000 a month, and we don’t cut any corners on any of them. I’ll put our barrels up against anyone for accuracy and durability.

Q: Can you talk more about your barrels? It’s hard to think of a company who has more offerings for the AR platform. Where does that passion to put out barrels in such a wide variety of calibers come from?

Bill Wilson, Wilson Combat – I’ve always been an avid hunter. Before I was a competition shooter or a businessman in the firearms industry, I was a hunter prior to that. That’s still my number one passion.

I live here in Texas on an 8,600-acre ranch and have access to 14,000 contiguous acres to hunt on. So, I am hunting almost every single day, at least for a little bit. Wilson Combat offering so many calibers come from that.

Not all AR calibers are suitable for hog and deer hunting, at least in my opinion. So, I first started building out 6.8 SPCs. That was our first non-5.56 caliber we did. It’s an o.k. caliber. I’m not going to throw any rocks at it, but it’s not .30 caliber or bigger, and frankly, I’m a ‘.30 caliber or bigger’ kind of guy. That led to us adding other calibers, almost all of them aimed at the hunting-type market.

As we started adding calibers, it then only made sense to begin doing tactical use stuff also, to do things like the Grendel, 6.5 Creedmoor, and others. The thought was, ‘well, we’re already doing so many calibers, why not add another one?’ (laughs). What sets our Wilson Combat AR barrels apart more than anything else is that we make sure we put the hole in the dead center of the blank.

If you start out that way and get the hole perfectly centered in the the blank, every bit of the process goes so much smoother, and you can hold much tighter tolerances than if that hole is a few tenths of a thousand off-center.

I’ve seen barrels made by the old Remington that went bankrupt that you could look at the muzzle with the naked eye, and you could see how off-center the bore was with the OD. There’s no way that barrel can have top-quality performance with a hole being way the hell off-center like that. So, that’s step one for us, simply making sure we get the hole in the middle. We’re very particular about that.

We also put a good, smooth finish in the bore, and we don’t try to use our rifling buttons until they are way past their prime. We’ll replace them as needed and not try to squeeze another 20 barrels out of them when they are, in fact, worn out.

Q: Are you still not producing some of your barrels at the moment?

Bill Wilson, Wilson Combat – Things were totally crazy last year and earlier this year. We had so many orders for 5.56, 300 Blackout, 300 HAM’R, .308, and 6.5 Creedmoor that we had to stop production on most other calibers that were not doing big volume numbers. Now, we’re pretty well through that phase, and we’ve brought back more models/profiles of the calibers I just mentioned. We’re also systematically trying to get other calibers back and into inventory.

Q: I can recall some years ago reading that 6.8 was one of your favorite calibers. What is your go-to, general-purpose AR caliber today when you’re walking around your property, etc.?

Bill Wilson, Wilson Combat – I’ve pretty much exclusively hunted with the 300 HAM’R for almost three years. I’ve played with a few other calibers, and I’m somewhat intrigued by .350 Legend. I’ve hunted with it some and have probably shot 40-50 hogs with it. The 300 HAM’R, though, continues to be my go-to and what I use every day. I have a Kawasaki Mule, and I have two rifles with me, one with a day scope and another with a thermal.

300 HAM’R was my baby from pretty much the ground up. All the history of it is on our website, but what I like about it is it fires out of an AR-15 sized platform, not an AR-10. This means you have the potential to build a short and light gun. I’m 68 now, and as I get older, I find that I like my guns shorter and lighter. (laughs.) I like that I can build a lightweight gun and still have up to 30 round capacity and virtually no recoil. I run suppressors on all of my guns, and with a can on, 300 HAM’R is about equal to a 5.56 with no can. It’s lethal and allows for quick follow-up shots…much easier than with a .308.

Q: There are so many choices for firearms these days. Why should someone consider purchasing something from Wilson Combat?

Bill Wilson, Wilson Combat – I see our company as having a few advantages over our competitor, one you have already mentioned. We have a big choice of calibers. We offer a wide selection of different models. We have both forged and billet guns. We build them with all sorts of different features. With Wilson Combat, you can get your AR precisely the way that you want it.

Nobody offers the barrel profile and caliber options that we do. Nobody that I am aware of is even close. You don’t have to pick from a handful of choices like with many other companies. For example, with a 5.56 gun, you can have about ten different barrel profile options, a variety of bolt stops, and probably six different trigger types.

From there, I’d ask your readers to look at our track record of excellence and our commitment to quality. Then, if you ever have an issue for whatever reason, we have a 42-year history of taking care of our customers. Anything that comes in for service, we pretty much drop what we’re doing to fix it and get it back to our customers as soon as possible.

The bottom line is that at Wilson Combat, we care about our customers, we love what we do, and we care about everything that we do as a company. I’d love for your readers to learn more about us, learn about our track record, and then perhaps give us a call and see what we can build for them. I can promise you; they will not be disappointed.

###