Why Choose Sprinco springs for your AR-15? To find out, Last fall, we had the opportunity to chat with the godfather of springs, Alan Dugger of Tactical Springs LLC/Sprinco USA. Life got in the way and prevented this article from appearing in a timely manner, but we are now excited to finally share it with you. Below, Dugger discusses his early involvement with firearms, the genesis of Sprinco USA, the Sprinco springs difference, and why, in his experience, no two ARs are the same.

Q: Alan, thanks for taking the time to chat. Let’s start with who you are and what your background is.

Alan Dugger, Sprinco USA – My name is Alan Dugger of Tactical Springs LLC / Sprinco USA. My background is that I grew up in Texas, and although my dad didn’t have a lot of guns, my grandfather and uncle did. Because of that, I was exposed to firearms at an very early age. We were trained well and trusted with guns around the age of 8 or so. I can recall my cousin and I going down to the creek with our .22s. So, it’s been in my blood for a long time.

My first career was in the construction industry, and I had a lot of exposure to engineering courses, although I wasn’t a professional engineer. I feel like I took on the problem-solving traits that my grandad, father, and uncle had – and I was always looking to find ways to build a better mouse trap. So, while I had a successful construction company in Austin in the late ’90s, I also started doing some gun show business as a side thing to get out of the house.

I had picked up some pistol recoil systems from a company called Chandler Arms, and I sold them successfully at shows around Texas. While assisting them at SHOT Show around 1996, I happened to meet someone from Sprinco LTD Israel, and one thing just sort of led to another. That meeting resulted in us becoming Sprinco USA, focused on recoil management systems for pistols.

Q: When did the idea for AR springs start? It seems like it would have been a natural progression.

Alan Dugger, Sprinco USA – Around 2006, a buddy approached me and twisted my arm, asking me to start making Sprinco springs for the AR-15. I told him I’d look into it. I quickly discovered that the rudimentary machines we had at the time were not up to making AR-15 buffer springs.

To remedy that, I found myself trading our equipment and some cash for an equity position in a precision spring company in northeast Ohio. Today, I’m proud of where we’ve gotten to, knowing that there are not that many true precision spring companies in the industry. Another thing worth noting is that my partner also sells spring machines, so we always have some of the latest and greatest CNC coilers in the industry on our floor for other spring companies to visit and look at. Today, we manufacture springs for many other spring companies in the industry who come and look at our equipment and say, ‘Hey, rather than us buying a machine, you guys make the spring for us.’ This keeps us pretty busy.

Sprinco AR-15/10 Buffer Spring

Q: What does “precision” mean regarding springs, without getting too technical?

Alan Dugger, Sprinco USA – Precision means +/- 5 percent of the represented load top is within tolerance. Commercial tolerance, which is prevalent, is +/- 10 percent of the represented load. On a relatively large spring like an AR buffer spring, 5 percent is a relatively tight plus or minus goal to hit, but we have no problem doing that.

Q: What AR-15 buffer spring did you make first, and how long before you decided to make other varieties?

Alan Dugger, Sprinco USA – So, we ended up selecting valve-quality chrome silicone for our Sprinco buffer springs, and the first one we did was our red buffer spring. At first, we had no big designs on branching out beyond that one, along with our extra power five-coil extractor spring. However, these products began to attract some attention. We didn’t advertise, and it was more word-of-mouth.

I actually attribute much of our early success to Mike Pannone of CTT Solutions. He came across our products and reached out, willing to share some of his knowledge and thoughts on what we could do to improve. As a result of his input, we went further than we had planned. He is the person who invented our blue buffer Sprinco springs. He did that by cutting three coils off of our red buffer spring and telling us that we needed to make a new buffer spring to that spring load. We took a look at his recommedation and got to work on it.

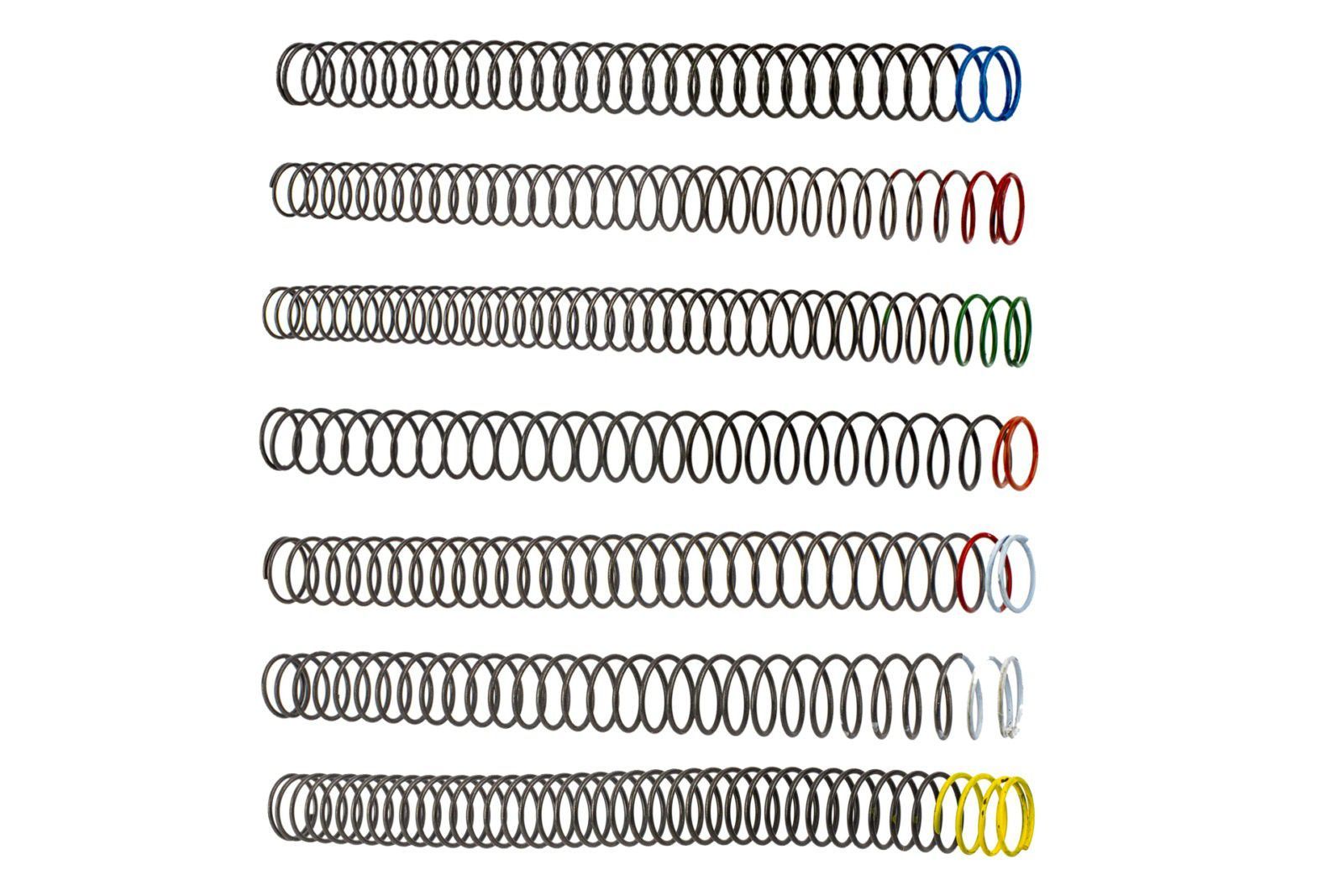

Q: How many buffer springs does Sprinco offer now? Also, I noticed one is called ‘hot white.’ Can you explain how that one is different?

Alan Dugger, Sprinco USA – We now have six carbine Sprinco springs and one lesser caliber rifle spring. Our hot white spring was the only one of our six carbine springs not purpose-designed and built. This Sprinco spring evolved from a run of 3,000 white springs whose production loads were right between white and blue.

I had set them aside as scrap, but then I started hearing from customers that while they liked the white and the blue, they wished there was something in between. I gave out a few of the springs I had set aside, and the feedback was that the spring nailed it. That’s how the hot white spring became a thing.

The other thing I want to leave people with is that when tuning an AR, the reward is worth the effort expended. Sprinco exists for our customers, those who believe being good is not good enough. To that end, I’m more than willing to share my knowledge.

Alan Dugger, Sprinco USA

Q: What are some of the most common misconceptions you see out there regarding buffer springs?

Alan Dugger, Sprinco USA – One of the biggest things I’ve learned over the years is that one size does not fit all. Springs are merely stored energy, and which one you choose to use in an AR is a big part of getting it to run right. As far as what the very best spring is, several factors control that. Using a medical analogy, you have to provide the proper amount of energy to match the symptoms being presented by the patient. In these days of instant gratification, many think of these parts as Legos and that you can tell what your rifle needs just by doing some basic surmising, but nothing could be further from the truth.

You and your readers may already know this, but there’s much to consider. In a direct impingement AR, you’ve got the power factor of your loads, land and groove ratio, barrel length, gas tube length, gas port size, suppressed or unsuppressed. All of those factors create the need for a different spring. Navigating all of this is something that I like to help my customers with.

These days, I spend a lot of time on the phone with my customers. This is something that I genuinely enjoy. I’ve been blessed with a very successful company, and I don’t have to sell another spring to have a perfect day, but if I can help somebody get out of the weeds, that is a privilege.

Having helped so many, I want to stress to anyone who reads this that even though two ARs may look exactly alike or have sequential serial numbers, if I focus on tuning them to what I consider perfection, each one might have a slightly different recipe.

Q: So, things are not as ‘off the shelf’ as you often see online?

Alan Dugger, Sprinco USA – I’ll put it this way – If someone is building a gun, there’s just no way on earth they can devise what the “perfect” spring and buffer weight will be without first shooting it, documenting initial performance, then contacting me with that documentation.

If they provide that to me, I’d be happy to help give them my recommendation based on years of experience and tuning a bazillion rifles. But again, we cannot predict the perfect situation for their AR right up front. Most folks are responsive to that, but some want instant gratification.

Q: What performance notes would they need to bring you? Performance-wise, what should they look for to know if they have the correct spring?

Alan Dugger, Sprinco USA – The primary things I need to know are barrel length, gas length, the type of loads they are shooting, suppressed or unsuppressed, and most notably, any malfunctions they are experiencing. I also want to know what their goals are. I can also glean information from their observation of the horizontal case ejection trajectory.

Case ejection trajectory is not the end-all, be-all, but the farther forward of 3 o’clock it is, the more indicative it is that carrier velocity may need to be optimized. Another thing that impacts ejection trajectory is having a good ejector spring, but even more so, a good extractor spring.

Q: Can you give a trick or advice on capturing this data?

Alan Dugger, Sprinco USA – I recommend going to our website to our buffer spring page and downloading a copy of our case ejection chart. Then, I recommend going to an outdoor range with a buddy, getting on a bench or prone, and properly getting their shoulder into the gun-have the buddy stand on a stool right behind the shooter, looking down. You then want them to log what the case trajectory is. I’d also add that when they are doing this observation, they don’t want to do it on a cold gun. They should fire two rounds to warm the gun up and start the documentation. The more information they can bring, the more quickly and comprehensively I can help them.

One thing I have found empirically through our tuning exercises is that in most, but not all instances, a heavier spring and a lighter buffer will shoot softer and with less muzzle and sight picture displacement than a lighter spring and a heavier buffer. This is attributed to the reduction in reciprocating mass imparted to the shooter’s shoulder, which wacks them harder and bumps the sight picture. The goal is a nice balance, and when this can be achieved, I can tell you that it puts a goofy grin on anyone’s face.

Unless you are changing something in your recipe, like throwing a can on it or dramatically changing your loads, as long as you are providing preventative maintenance, the spring loads themselves are not going to change typically for longer than both of us together can afford to buy ammo to shoot it.

Q: Forgive the perhaps fundamental question, but what accounts for the longevity?

Alan Dugger, Sprinco USA – It’s due to the valve-quality wire we use. We also dual-stage shot-peen them, giving us a long duty cycle. Typically, the spring design software notes that our springs are rated for over a million cycles, many of them far more than that, but not many people, including myself, can afford to shoot that much. Keep in mind, too, that none of my buffer springs are exact copies of anything “mil-spec.”

The closest we have to a standard buffer is our white spring. It uses a different wire size versus a “mil-spec” spring, but we took the design notes of the latest M4 TDP and added a few percent without regard to the overall length of the spring. With our springs, the length is pretty much irrelevant. Instead, it’s all based on the spring design. We also attribute the longevity to cryogenic processing, which we perform in-house. It does some serious magic as far as extending duty cycles. It’s under the category of heat treatment and stress relief and will extend a spring’s duty cycle 3 to 7 times.

Q: How long have you heard of Sprinco springs lasting in a hard-use situation?

Alan Dugger, Sprinco USA – On our extractor springs, the longest documented 5-coil spring I have out was one that Mike Pannone used over six years while teaching carbine classes for some first-tier groups. He moved around the same 5-coil extractor spring and Crane o-ring from bolt to bolt. He also used the same cut-down red buffer spring he used to invent the blue spring during this period. These springs were on suppressed SBRs running hot, hard, and heavy for a documented count of over 238,000 rounds of NATO-spec ammo, with no degradation in performance.

Sprinco M4 / AR-15 Extra Power 5-Coil Extractor Spring Upgrade Kit – 3 Pack

Q: Can you explain why someone might want to swap out an extractor spring to one made by Sprinco Springs?

Alan Dugger, Sprinco USA – In the very beginning, the same guys who tasked Sprinco with developing the red spring also wanted an extractor spring that would negate using an o-ring as a crutch for a less-than-beefy extractor spring. These folks were very concerned with the M4 reliability regarding the Global War on Terror. As a result of that request, we designed the 5-coil spring, which you run either with the black insert or the o-ring, but not both. It’s a stout spring appropriate for barrel lengths 16” and under and lesser calibers.

In lesser calibers with barrel lengths 18” and above (principally if they are retrieving the brass for reloading), we have an enhanced 4-coil spring, which is less aggressive on case rims and not as necessary for serious, positive extraction. The shorter the barrel, the more critical a good grip is, as everything is happening much quicker due to dwell times.

Q: Another fundamental question – what is valve quality wire?

Alan Dugger, Sprinco USA – It’s based on the alloy’s granular consistency and the post-extruding surface finish. Valve quality wire exhibits the highest quality, smoothest finish possible. All of our Sprinco stuff is manufactured in the US, but one caveat I share with people is that in 1970, President Nixon signed the Environmental Protection Act. One of the first things we lost the ability to manufacture in the United States was valve quality wire, as its production requires arsenic.

None of our stuff is sourced from nefarious countries. It was initially sourced from a mill in Canada that went out of business. Then, we got it from Sweden, but they were slow. So, around 2016, Sprinco switched to mills in Japan that make the world’s highest-quality DFARS-compliant valve quality wire. Regardless of our springs and what they are made from, my primary focus will always be consistency, reliability, and durability.

Q: When should someone consider switching what they have in their gun to Sprinco springs?

Alan Dugger, Sprinco USA – While our springs are more expensive, they are worth it because of their longevity and consistency. First, I’d say that if someone has a brand-new DI gun, you need to shoot a few mags through it to seat your gas rings. After that, if you’ve got a gun that is ejecting cases every which way without consistency, that can indicate a cheap spring and a buffer not necessarily optimized for that particular rifle.

With typical “mil-spec” springs, you’ll hear people complain that they hear a ‘twang’ and are kind of loud. Several things are going on that cause that sound. First, you’ve got the rougher surface finish of the wire. Then, you couple that with the finish and anodization of the receiver extension. If you check the outside diameter of a “mil-spec” spring, you will find it will be a little smaller than a Sprinco spring. If it doesn’t have a rod or shaft, the axis of that spring is going to shift from side to side, looking for an “escape hatch.” That’s not possible, so it shifts from side to side during compression, and when it bottoms out and is released, it does the same thing on the return. All of this together is the principal cause of “twang.” We don’t promote that our springs are technically quieter as a marketing feature, but it comes with observation.

Q: Are there things I have not asked that you hoped I would have about Sprinco springs, or do you wish people knew but don’t?

Alan Dugger, Sprinco USA – One thing I emphasize to our customers is that for buffer springs, they use a good, high-quality grease on the surface finish. Some examples are Slip 2000 EWG or some of the Lucas variants. Some people will say that chrome silicon will rust. To that, I say the baby will get a diaper rash if he’s not protected. Another important thing is never to use chlorinated brake cleaner or solvents containing chlorinated ester to clean springs. It can cause chloride corrosion and engender hydrogen embrittlement.

I’d also like to stress that I love my job and helping those who ask. Frankly, I am old enough to retire, but I’ll keep doing this until they haul my old carcass off in the donkey cart because I love what I do. It’s very fulfilling and rewarding, and I’ve had the time of my life, and that’s because it’s a labor of love. What brings me happiness is improving the quality of someone’s shooting. That’s what gets me excited. That, and doing some oddball OEM things. Not just buffer springs, but all sorts of stuff for other industries. I love creating solutions for difficult situations. That’s what floats my boat and always will. I couldn’t ask for more.

The other thing I want to leave people with is that when tuning an AR, the reward is worth the effort expended. Sprinco exists for our customers, those who believe being good is not good enough. To that end, I’m more than willing to share my knowledge. I’m an anal-retentive perfectionist. I’ve learned much from people like Will Larson and Chad Albrecht at the School of the American Rifle. I was friends with Will for years before I took his class; may he rest in peace.

I sure don’t know it all, and tuning ARs can sometimes be tricky and puzzling. You’ll be expecting one thing only to scratch your head at how the rifle is performing, as it seemingly defies the laws of physics. It’s easy to feel stuck and alone. At that point, you have to back up and start going through the motions one at a time. Of course, in a perfect world, everyone would have at least one of each of the Sprinco springs, especially if they are building a ton of rifles. That way, they’d have a tuning set to run through and test with.

In the end, when it comes to ARs, there’s just no predicting it. Not getting out there, shooting, and doing proper vetting will lead to disappointment. Above all, remember that the more effort you put into something, the bigger your smile will be in the end.

###

Great stuff. Love the AR nerd stuff

Sprinco is my go to source for AR springs..Great article..