Chad Albrecht at School of the American Rifle is teaching students how focusing on the little things is of huge importance when it comes to a dependable, reliable AR. In part one of our two part conversation, we talk to Chad about the beginnings of the School of the American Rifle, common builder misconceptions, and we discuss the ebb and flow of quality control within the firearms industry.

Q: Chad, can we get a little bit of background on you and the beginnings of the School of the American Rifle?

Chad Albrecht – School of the American Rifle: Initially, as a young gun owner, I was enamored with the AK series of rifles. After I got out of high school, I started buying my first firearms. A local gunsmith was the guy I would go to whenever I needed something…any install I couldn’t do, etc. We developed a pretty good relationship. He and his father had started the business and he had been gunsmithing for 20 plus years. His father passed away and he needed someone to help out. He didn’t necessarily need another gunsmith, but he definitely was always backlogged.

I came in one day to give my condolences about his father passing and he was like, “hey, I’ve seen the stuff you tinker with, and I think you have the eye and the hands for being an apprentice.” I accepted the job. He paid me whatever minimum wage was, and he had me doing clerk work up front…paperwork and clerical work.

Contract with a Tradesman

He would then teach me things in the back…He basically taught me everything he paid to go to school for…the old way…sort of like the way they used to teach someone a trade in colonial Williamsburg. You would basically get into contract with a tradesman if you wanted to learn a trade. You’d give them a few years of service, and they’d teach you what they knew…and that’s basically what happened.

A few years was the term that we were supposed to do before he let me do my own thing in the back, but by around the nine month mark, he was like, “O.K., I’ve trained you enough. I really don’t have anything else I need to watch you with.” He then cut me loose and let me work on things as they came in without worrying what I was going to do or if I was going to mess up.

He was an old school gunsmith, so it was more “sporting rifles” and things like that. However, I still had that tie to my liking the AK…but as I started working on them as time went on, I started liking them less and less. I started to appreciate firearms like the Glock and the AR…mostly due to their modularity. You could purchase a part, and for the most part, they dropped in. You didn’t have to do a lot of work. I began to appreciate firearms that did not require a lot of fitting, like the 1911. So, I started from there.

Now, I did start to get known for doing some AK work locally. At the same time, I was becoming enamored with the AR and I really became interested in it and educating myself on the “right way” to do things. Because of that, I started building a name for myself when it came to ARs too…

Small Beginnings

What would happen was people would come in and have questions, just like anyone does on the internet, and I would essentially hold miniature classes up front in the retail area…I’d have a crowd of 5, 6 or 7 people listening to me give a rundown of a gun or explaining a modification or an accessory. As time went on, people began telling me I should offer it as a class, and that they really liked what I was offering. So, I decided to do a few small classes with people that I knew. From there, it just became an occasional thing for me…bubt it developed into essentially a school, and the rest is history. I’ve been doing it a few years now and it’s been quite enjoyable.

Q: Can you talk about what sorts of classes you offer?

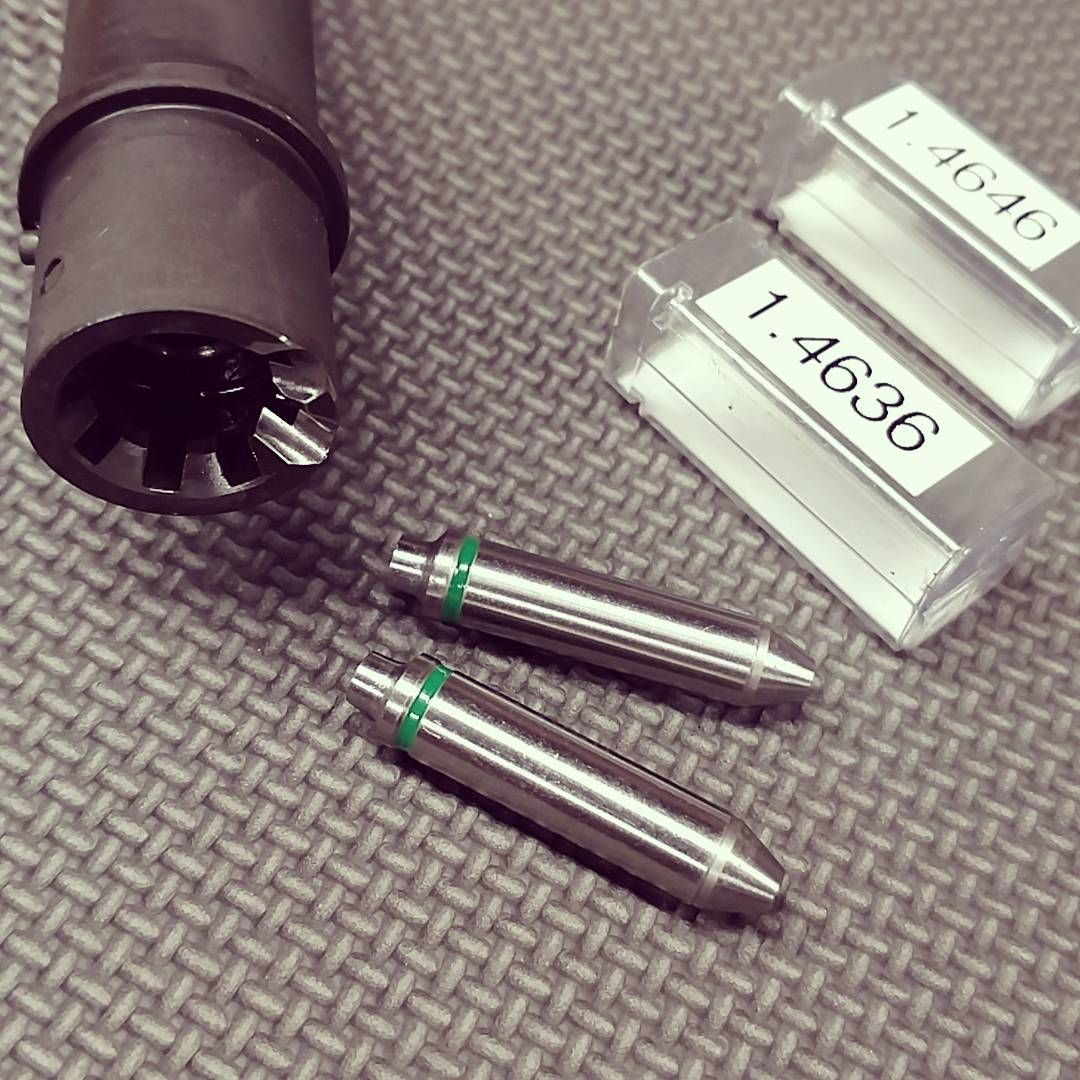

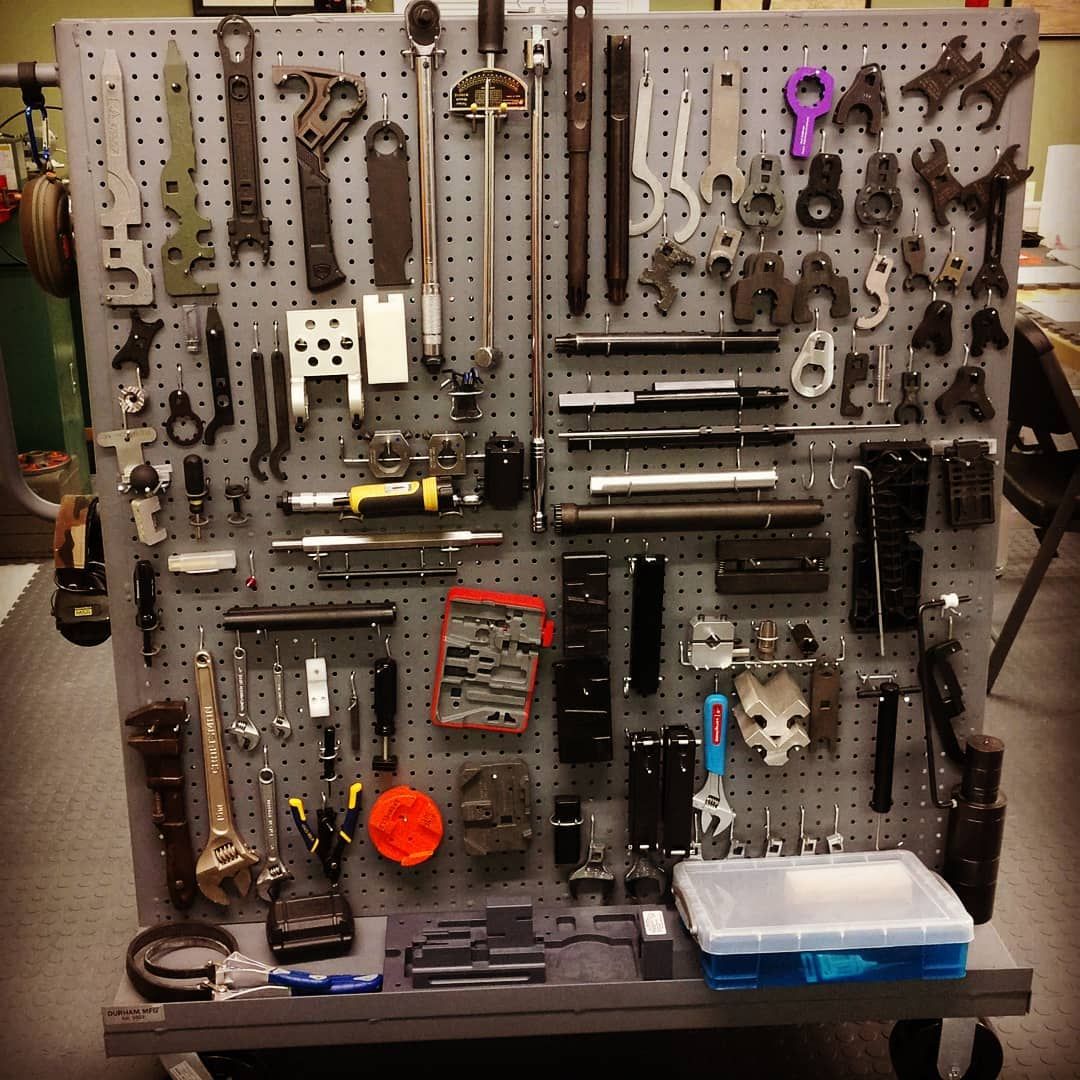

Chad Albrecht – School of the American Rifle: I offer two different classes and I do offer them back to back. The primary class I refer to as an armorer’s class…I also call it a “101” class. I go over a basic understanding of the operation of the weapon, proper assembly, things you want to check for. As a value-added thing I add, I think I pretty much have every tool and gauge that has been made for the M16.

In the class, I go through the different gauges, how to use certain gauges, how to check things without having the more expensive gauges…things you want to look for as far as feed ramp geometry, and the basic things you’d look for if you were to review the 23&P military manual. I also integrate a little bit of gunsmithing, a little bit of armorer’s work…I turn all that into a basic curriculum.

Q: How far do you take the gun down in a class like this?

Chad Albrecht – School of the American Rifle: I really don’t do anything beyond field stripping the AR in the armorer’s class, so if you bring a gun, we’ll take it down to field strip position…maybe take the fire control pack if you’re comfortable. I don’t mandate that people do it. There’s no pulling barrels off or things like that unless there is a serious problem. If someone comes in and their barrel is loose, of course we’re going to fix that, but we don’t pull everyone’s barrels off.

From there, it’s the build class…you can either show up with a box of parts, or you can bring an assembled gun. That can be value-added because some people have never torn down an AR completely. They may have only purchased parts kits and put them together and they don’t know the little tips and tricks for tearing things off the gun…

Essentially, I take a lot of the knowledge from the armorer’s course and I just apply it to the students where they do the work and I’m just over their shoulder telling them what they are looking for, what they are going to gauge, how they are going to fit something if it does not fit properly. Whereas most armorer’s courses, it would be more of “ok, that part doesn’t fit…let’s use another part.”

Rather, I show them how to overcome those problems and make something work that maybe wouldn’t work before…so it’s a little bit different from what I would call a “standard armorer’s course” that you would take from a manufacturer. It’s more what I’d refer to as a blended course…a little bit of gunsmithing, a little bit of armorer’s work.

Q: Are there big picture things that we’re missing as AR builders?

Chad Albrecht – School of the American Rifle: It’s something that was touched on in your interview with Will Larson. People in the industry constantly refer to ARs as “Legos”…

The common understanding is that an AR15 barrel is set with its headspace. So the barrel extension controls headspace and you should not have to check headspace on an AR. Using gauges…you’ll see about 20% of all AR barrels on the market are not headspaced adequately to chamber a round safely. They’re usually short.

That’s about one in five…You’ll see a barrel that if you take a bolt and you take your headspace gauge and you drop it into the barrel, try to rotate the bolt, it won’t go. There’s a certain amount of force that the military manual calls for…I think it’s around 7 pounds…even if you apply that much force it still won’t go. It’s a problem across the board with the understanding of the gun.

People will then say that if the headspace is short, the brass casing will just compress and it will chamber a round. In some cases, that happens. But when you introduce things like fouling, the gun gets hot, the gun is not sufficiently lubricated, it’s possible for the gun not to go into battery…and if it is a perfect storm of things, it can be dangerous.

School of the American Rifle – Costly Assumptions

It’s an issue where people buy a barrel from a well respected company and they assume that they would have checked it. Sometimes it’s something that’s just missed…sometimes its what people refer to as tolerance stacking where Company A makes a bolt to a certain tolerance and the bolt face is cut deep, or maybe there is a coating on the bolt that causes the dimensions to change ever so slightly…and you add that to a barrel with a particular coating or a lack of coating, and then those two things don’t play well together.

Q: Teaching at School of the American Rifle, can you tell our readers about what you look for, or perhaps more importantly, what to be wary of while parts shopping?

Chad Albrecht – School of the American Rifle:The biggest issues I run into is companies copying other companies terminology or what they’re saying they’re putting into things. So, I’m always cautious of a company that offers a “duty grade” bolt carrier group and it hits all of the checkmarks for certain steel, certain coating…but unless you have specific equipment to test, you really don’t know what it’s made of.

There’s a lot of stuff I believe is getting imported from overseas and it’s concerning to me because it’s essentially a bomb next to your face…and if you’re not sourcing parts from a trustworthy source, it can lead to serious injuries or worse.

So, if I know that I have to trust a gun, I go to places that are making things for law enforcement agencies or things along those lines. There are deals to be had, but there’s so many fingers in the industry that the regular joe can’t sift through all of that information and come to an educated conclusion without some sort of training or without spending a lot of their time educating themselves on what is truly something that would be called “duty” grade or what I call “trustworthy.”

“Theres sort of a tide that I’ve noticed”

I have my own hand-selected parts that if people ask me I will tell them try this, this and this…but I try to steer away from recommending particular companies because overall there’s sort of a tide that I’ve noticed in the industry for as long as I’ve been in it. Just because a premium company makes a premium product now, that doesn’t mean in six months its going to be the same level of quality, if that makes sense.

I try to keep my finger on the pulse of the quality of stuff as I help people work on things, build things, gauge things…and I try not to be overly critical when I talk about things, especially on social media where people can take offense to it…and they do. People treat this like it’s their child that’s been insulted when you talk critical about a certain AR component or a certain company. But it’s always changing…

Now, it does not mean that if you buy cheaper parts that you cannot build a reliable gun, it just means that the chances of having an issue and being required to do more fitting or replacing things are higher.

###