We recently sat down with Kyle Lynch of Riflespeed to discuss his approach to the adjustable AR gas system, called the Riflespeed Gas Control system. We discuss how the idea came about, issues with other adjustable gas systems, and why he feels Riflespeed’s Gas Control system has the potential to change the approach of AR manufacturers in the years ahead.

Q: Kyle, thanks for the time. How did the Riflespeed Gas Control system come about?

Kyle Lynch, Riflespeed – The project started about eight years ago. I was shooting a two-day rifle match in the carbine division with a 16″ mid-length AR with factory ammo. It was a great rifle that was very accurate and entirely reliable. On day one of the match, it was about 70 degrees, and on that day, I shot one of the best matches of my entire life. I was in first place at the end of day one. Mistakenly, I went to bed that night thinking that I had it in the bag, the trophy was mine, and I was thinking about all of the items that were on the prize table…all of the things that you shouldn’t be thinking about after the first day of a rifle match. (laughs).

I woke up the next day, and there was a foot of snow on the ground and sub-freezing temperatures. I got out on the course and I figured out very quickly that I now had a single-shot rifle. I had to break position between each shot to manually cycle the gun, which would no longer function. It was a disaster

Q: Can you explain why that happens when you swing from one condition to another as you experienced?

Kyle Lynch, Riflespeed – On our website, I have two articles that I have written relevant to that question. One is called “In Balance – The Operating System of the AR-15 and AR-10 Family of Firearms.” This article lays the foundation for the shooter’s understanding of how the AR gas system works.

The other article is “The Fallacy of the Ideal Gas Port.” This talks about the changes that an environment can have on a rifle and how there is no such thing as one gas port that can handle all of these situations and conditions with perfect performance. It cannot happen.

In my situation, when the temperature dropped, most ammunition and gunpowders display temperature sensitivity. This means that the performance of the gunpowder – the burn rate, peak pressure, the time curve of the burn – all of those things will change based on cold or hot temperatures.

Years ago, when I worked at Barrett…we did a lot of work with ammunition companies on temperature stability, and different ammunition based on SOCOM’s requirements. I learned that even gunpowders marketed as temperature stable would display some change based on temperature swings.

So, on day one of my match at 70 degrees, the gun ran great. The ammunition ran great, and everything was as it should be. However, on the second day, when the temperature was so cold, the burn rate of that ammunition’s powder changed. The peak pressure (close to the chamber), and the port pressure (near the gas port), changed. So now, there was not adequate pressure at the gas port to cycle the action of my rifle…

Conditions, when they change, will affect the performance of your ammunition. Cold weather can affect metal parts on your rifle and can even impact the performance of the lubricant on your gun. Understanding that “things change,” as basic as that may sound is important, it also why in my opinion, there is a real need to have an adjustable gas block on every gas operated rifle.

Q: What you describe makes sense, but I’ve often read to avoid adjustable gas blocks. Can you address that, and how does that relate to what you are offering?

Kyle Lynch, Riflespeed – So, my experience started me down the road of researching and using adjustable gas blocks. I purchased and broke every single adjustable gas block on the market at the time. They all used the form factor of a low-profile gas block with a set screw for adjustment. They all failed on me.

There were general problems with solutions that were on the market at the time. For example, the adjustment screw seizing, the adjustment screw eventually embrittling and breaking, needing to always have an adjustment tool handy, having to stick my face near the muzzle of my gun to find a tiny set screw. These were just not acceptable for a duty or tactical weapon.

To address your question, avoiding those adjustable gas blocks would be solid advice, especially if we are talking about a tactical, defensive, or hard use gun. I took them off guns that I might select for possible home defense or any real application. As far as a competition gun, it’s always been acceptable to have an adjustable gas block there, because honestly, the consequences are just not that severe.

The Riflespeed gas control, from the very beginning, was conceived, designed, developed, and validated to be a military or duty grade system. There is no compromise, no B.S. One did not exist prior for the AR. You had some proprietary systems on specific guns that were selectable. You could select a “suppressed” setting that the manufacturer had chosen for that gun and an “unsuppressed setting.” While that’s probably better than nothing, they are compromised settings, and it’s not genuinely adjustable as it does not account for the variations in ammunition, suppressor backpressure, and various conditions.

Q: So, can you walk us through the development process?

Kyle Lynch, Riflespeed – As I began developing the Riflespeed gas control, I laid out criteria that would allow us to create a duty grade adjustable gas system for the AR. It must be usable with no tools. It had be simple, robust, and made with large parts. The Riflespeed gas control is made of four machined parts.

The very large, robust spring you see on it was developed by a group of people behind many of the springs you see on suppressor mounts throughout the industry. It’s the same people, same material, and same technology. It’s a very well-proven spring system.

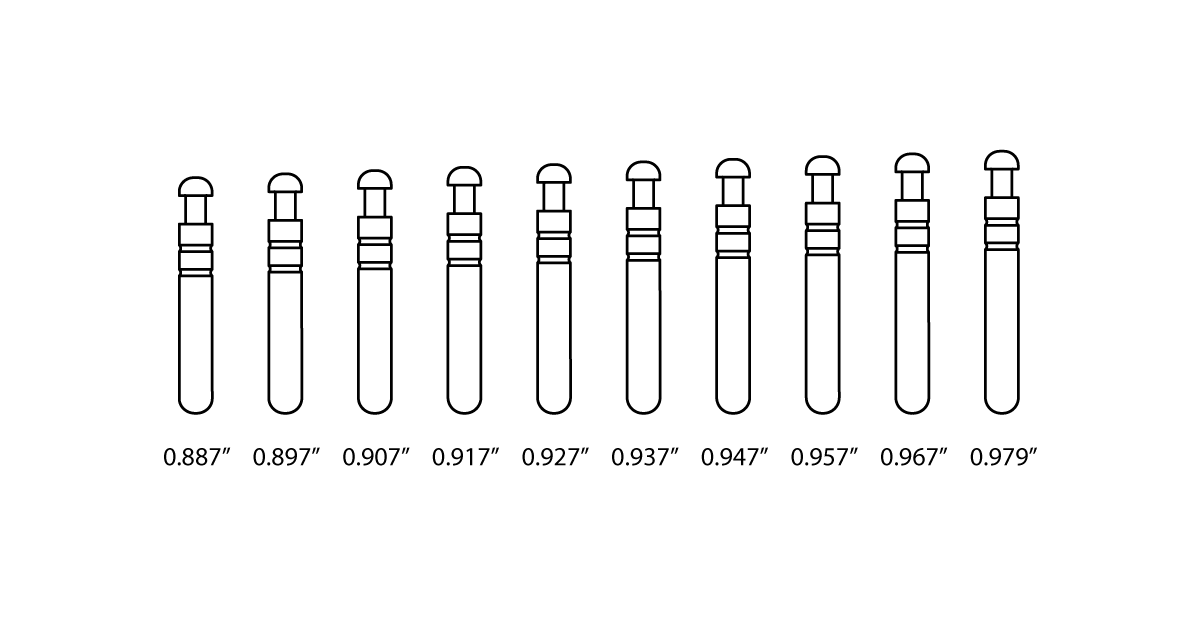

Finally, the system also needed to be modular. If you watch the video of how our Riflespeed gas control is put together, you’ll see a robust little plunger. We supply different plungers with each system we send out. It’s completely smooth with no threads that can become fouled with carbon. I’ll touch more on this plunger in just a moment.

I tell people frequently that this is really a “no compromise” system, which is why it is so expensive. I often say, “that if price is the biggest complaint, then you’re probably doing something right.” I say that from the point of view of someone who looks at firearms from a serious perspective.

I was not going to make compromises that would either reduce the cost or reduce the durability or performance of the system. Yes, that does mean it is going to be more expensive. It also means that there are things about the Riflespeed gas control that people may not like or be used to. One example of that would be the straight gas tube that we use. Many people think that’s some weird thing that has not been done before, even though Colt, Knight’s, LMT, etc., have used straight gas tubes.

The decision to use a straight gas tube was made because it allows us to build a stronger, more robust product. If you look at the low profile, set screw gas blocks that are out there, there are some very thin walls between the hole where the barrel goes through, the hole where the screw goes in, and the hole for the gas tube. Some of those areas get very thin, and then you add a threaded hole which has sharp v-shaped cuts that are even thinner at the bottom of that v.

That’s a weak point. We moved away from that deliberately. As a result, we have not yet been able to destroy a Riflespeed gas control. We have done a lot of deliberate destructive testing, and so far, all we’ve been able to do is burn out barrels and blow up suppressors. The barrel or some other part of the gun will fail first, which was our goal.

The wear item on the Riflespeed gas control is actually the plunger. That is the part intended to take the abuse of the hot blast of gas, wear down, and be replaced eventually. If you solely went out and mag dumped with a semi-auto rifle as fast as you could shoot until rounds started to cook-off, you will get 10,000-20,000 rounds out a plunger that is an $18 part that can be replaced with no tools in about one minute.

The modular nature also means you can do some very interesting things. We offer a variety of different-sized plungers. As an example, if you were running 300 Blackout, you could potentially configure your rifle to where setting number 1 would shut off the gas completely, preventing the bolt from unlocking after firing. This would eliminate ejection port noise, giving you basically a bolt action rifle, and the quietest AR-15 that could exist. Then, within a second, you could reach up and dial up to a different position to make the gun cycle again and have a functioning semi-automatic or fully automatic rifle.

Q: At what point did Riflespeed start offering complete uppers?

Kyle Lynch, Riflespeed – We launched the Riflespeed gas control system in 2021. We’re still very new on the market. Immediately, we had an enormous response. Everything sold out, and we began making more. We’ve been able to keep things mostly in stock since then. Almost immediately, we got e-mails from customers that said they didn’t have the knowledge, experience, confidence or time to do their own assembly or build.

They were asking if we knew of anywhere selling the entire upper with the Riflespeed gas control system pre-installed and ready to go. At the time, there was no one. Since then, we have signed a few OEM deals where we will have factory-built rifles coming out very soon that will have a Riflespeed gas control system installed from the factory. That’s in the works.

The requests kept coming in, so we decided to make our uppers to act as a turnkey solution for those who don’t have the desire or ability to build their own. This has been a popular option.

Q: These appear to be quality uppers with quality parts. Can you mention who you’re working with to build these uppers?

Kyle Lynch, Riflespeed – We have a lot of industry friends that we work with. Cross Machine Tool is my neighbor. He’s about 10 miles away, and we’re big fans of their handguards from a quality standpoint, regardless of the fact that we’re close. We use a lot of their handguards.

We try to offer several tiers of components on the different uppers that we sell. Most tasks can be completed with a service-grade nitride finished barrel that costs around 100 to 150 dollars. There are lots of them on the market, and brand is not particularly important. They are going to be relatively similar. In my opinion, if you’ve got a red dot on a gun, you don’t need to spend 400 dollars on a match-grade barrel. So, we offer that…a standard receiver, with a nitride-finished barrel by one of a few very well-known manufacturers. Depending on the barrel, we do inspect every gas port, and we will open up the gas port slightly on some of those.

We then have higher tiers where we will use Colt or Criterion barrels; some match barrels occasionally, depending on what the customer wants. We just want to have a good range of options for the guy who wants a good, reliable home defense, farm defense, truck gun, etc. He doesn’t have to spend that extra 500 bucks and have the absolute best of everything.

Q: What are the some of the reason why you’d want to begin adjusting? Are there symptoms to look for that indicate when it’s time to dial it up or down?

Kyle Lynch, Riflespeed – There are several issues that you could notice. I’ll go through some in no particular order. If your bolt does not lock back on an empty magazine. That can indicate not enough gas going back to the rifle. It could also be an indicator of a magazine issue.

Generally, if your brass is going anywhere forward of 3 o-clock, you probably need a little less gas. If you notice the sights moving off the target significantly, you may have the opportunity to turn the gas down.

One application for this that has not been explored as much as I think it could be yet is the Riflespeed gas control system’s usage on a precision rifle, as you could turn that gas down where you have 100 percent reliability but your gun shoots much softer so that your sights don’t leave the target, at all in some cases.

If you notice the feeling of torque when you shoot your rifle, that can be another indicator. I’ve got a Mk18 build that was my go-to for years, but it is so over-gassed with a suppressor that it torques and rotates in my hand and against my shoulder every time I shoot it. It has an older barrel with a huge gas port. With the Riflespeed gas control system installed, you can do a full auto mag dump into the face of the target, and the dot never leaves the head. It’s amazing.

Now that we’re going into Spring, watch the performance of your AR as we go from Spring to Summer. Make a note of the sensation of recoil – how it feels when the gun moves, how fast it seems, and how much your sights move.

Also, any time you have a reliable rifle without a suppressor, if you put a suppressor on it, even if it is one of the flow-through or low back pressure models, it is unavoidable that there is going to be some change in that gun…The suppressor mitigates the sound by delaying the release of the gas into the open air. The fact that it delays that release unavoidably changes the timing of the gas system.

So, any time we change the duration of pressurization of this system, we deliver more gas to the action unless we have a way to reduce the size of the aperture through which that gas is flowing. That’s the job of the Riflespeed gas control system.

I can physically diminish the space the gas can flow through so that now that the system is pressurized for a longer time, and I’ve not significantly increased the volume of gas going to the action. Without a way to mitigate the gas at the port, you’re going to have too much gas delivered to the action if you have a suppressor on the end of the gun that is reliable without a suppressor. There is no way around it.

Look at what a lot of the industry has accepted as fact – that you’ve got to have a smaller gas port, and you have to find this compromised size that will work for everything. Well, it works for most things, but most of us never discover the difference because most of us don’t go to the range when it is 10 degrees outside.

We, as manufacturers and builders, now have the opportunity with the Riflespeed gas control system to deliberately oversize our gas ports without the negative consequences. I genuinely believe it’s the missing piece…I understand that might sound somewhat controversial because it’s such a big shift from what we’ve been doing – that an oversized gas port is the worst thing you can have. It’s not. I think all of this is going to change as the Riflespeed gas control system becomes more known and understood.

It is a very robust, reliable system that essentially removes the negatives of what we’ve had before with adjustable gas systems. It creates an opportunity that didn’t exist before.

###

Looks like the adj gas block I have been looking for. Easy to maintain, adjust and service. The large adjustment spring is not buried in the gas block plus it has limited contact to the high heated gas block looks like a winner..

As an update I can say without reservation the Rifle Speed Adj Gas Block is the best on the market..It makes all others obsolete..My only complaint is the adjuster spring was a little light for my taste..No problem, I stacked two springs together and the spring tension was fixed..The ability to put the correct plunger length into the adj gas block makes the system perfect..Different rifles will have different adjustment needs and the Rifle Speed does it right..To say I’m a fan is an understatement..Well done!