We recently reached out to RailScales to learn more about their highly regarded products, including G10 and polymer textured rail covers for ARs. I currently run the Dragon Railscales on my go-to AR-15 and have been very impressed with the feel, look, and overall sense of quality on display. To learn more, I spoke with RailScales product engineer and co-owner, Derek Shelton.

Q: Derek, can you start with an overview of what exactly RailScales are?

Derek Shelton, RailScales – Our flagship product and what we are known for are RailScales, which are textured G10 rail covers, or grip panels. We started in 2014. I was an NFA retailer at the time, and I was selling a lot of Keymod guns, and guys were asking, “what can we put on this?” There really were not a lot of offerings at the time. I came up with the concept, and before long, I realized that they were selling faster than we could make them.

We decided that maybe we would try it as an avenue of business. The rail covers were our core product, but we expanded on that with our Karve hand stop, which we have been selling for a while now. At this point, we’ve sold tens of thousands, and it’s been a super popular product.

We take a lot of pride in what we do, and we’d put it up against anybody. We are focused on using the best materials and the best machining to make the best products possible. Now, our products are expensive, but that’s because they have a lot more machining than any other things that are out there in the same category.

For example, we have a the RailScales RSB, which is sort of a vertical stubby grip…and the price for it is over $100, but it’s a machined aluminum grip that is lighter than a polymer grip. To do that, the boring operations and all the machining takes around 38 minutes.

Q: If you had to express what the RailScales philosophy is, how would you express that to our readers?

Derek Shelton, RailScales – Our philosophy on making a product is to use the be best materials we can, use the best machining we can, best finish, best packaging…and then we set the price. A lot of other machine shops do just the opposite of that. They say, “ok, we want to have a product in this segment, here’s our target goal for materials and machine time.” Then they have their engineer make something within those requirements.

A lot of machine shops work that way, and they make fabulous products, but we decided to do the opposite. We start with the design first and don’t set any parameters to limit it. For example, our QDX sling mount that came out recently…it’s in line with the bore of the rifle. It’s a single MLOK slot. We wanted to get the sling footprint lower. As we started doing it, we got it to where an H&K sling hook would work in it as well. It’s also a barrier stop. We then got it to where it weighs basically nothing. The goal when we started was actually, “what if we could make a cheaper sling mount?” because the biggest complaint about our stuff is that it is expensive.

So, we really did start with the intent to make it cheap, but as we added a lot of functions and used really good materials, and being that it’s also a pretty complicated part to machine to get all the geometry just right…the result of all that, It’s almost a $70 dollar sling mount now. So, it’s an interesting philosophy we’ve chosen, and it does not work for all shops.

Q: Can you explain to our readers how the different patterns on the RailScales came about?

Derek Shelton, RailScales – You could give any five guys the same task, and there’s going to be five different ideas. I have been the core designer here since day one. My business partner, Brent McGuire, also weighs in on that as well. What we do all comes from the same mind. Also, I don’t actually have any engineering experience. In regards to why the products look like they do, after high school, I found myself in a two-year gunsmithing program. There, we had to learn how to machine with no digital readouts, how to weld, how to make wood stocks. We had to forge our own chisels.

I got out and moved to Tusla, Oklahoma, where we are now. I started doing a retail operation. This was before Silencer Shop and online suppressor sales…so I was a very big NFA dealer. I kind of got tired of the retail thing. I had ideas and wanted to do other things like Railscales.

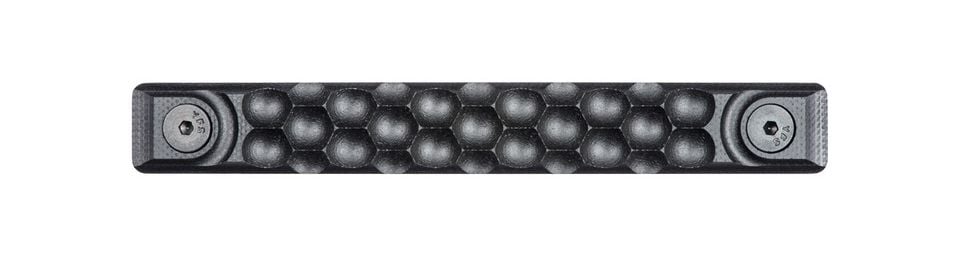

As far as the design, the first one was the Honeycomb, which I made on a drill press. I came up with the pattern in my head. The “Gen One scales,” as we call them now, they ended up being very sharp. I actually had to include sandpaper with them. I didn’t know anything about CAD or product design. The idea was that I would just make some for myself. I wasn’t really thinking of a business…it was rather crude. As time went on and we realized that volume was needed, we explored many options, but in the end, I decided to save up some money and buy SOLIDWORKS (computer software) and taught myself how to use it. It took years to become fluent, but with it, we’ve been digitally designing products since 2015.

After Honeycomb, we did one that we called “Peak Valley.” They had finger grooves, and were very simple. After that, the next one we did was the Dragon. Dragon actually had its roots back at gunsmithing college. I still have somewhere on my desk a 1” cylindrical piece of barrel stock that I did a dragon texture around the outside circumference using a manual indexing machine. It was a very labor-intensive process I did for a grade.

It was also a pattern that I had to do on my 1911 slide. I took all my old notes and measurements from that and simply applied to some G10. It worked awesomely.

MiniDot was an exercise in surface area. I wanted to see how much surface area I could create on the G10 scale for heat reduction and maximum cooling. I calculated what size tool to use, as well as spacing and depth to maximize that footprint.

Matrix is the same thing, but also an exercise in us wanting to cut a textured scale just using one cutter…I did that to see if I could do it, as well as to maximize how many cuts we could get on that scale.

Q: This is interesting and something that I was not aware of.

Derek Shelton, RailScales – Yes, it’s something that we’ve had people ask for…something like a texture comparison chart. We’ve been working on one internally. It’s an easy thing to look at them and see that there are four distinct scales, but in a way, the scales are subjective. How do you describe what something feels like in text form? We’re working on the way to convey this information to a consumer who is not sure.

Q: Perhaps discuss from an aggressiveness perspective?

Derek Shelton, Railscales – Going off the cuff from which one is most aggressive to least aggressive…Matrix is probably the most aggressive. It’s the kind of a pyramid-checkered one. We recommend that one for guys who are going to be wearing gloves. Guys who wear gloves tend to need more of a bite than if they are not using gloves.

Matrix are the RailScales that we recommend to guys LE guys, military guys, anyone who is going to be muddy, wet, or in an overall unfriendly environment.

Dragon is below Matrix in terms of aggressiveness and is pointed one way and smoother another. It is one that we recommend to guys who might be pushing or pulling back on their rail…we’ve actually seen guys mix and match which directions they put them.

Honeycomb is next and is our best seller in all of our product categories. It’s a great do-it-all selection that is good for gloves, aggressive with the hand, but it’s not going to cut them. It’s good wet, dirty, and it looks good. It’s an excellent all-around texture.

The MiniDot scale we recommend to guys who are not going to be wearing gloves. The MiniDot is unique in that when it is dry on a bare hand, it is grippy, but as it gets wet, it gets more grippy. As such, it’s good for someone who might be sweaty outside during the summer months on a hot day.

Now, all that said, most of our consumers buy them based on which look they like the best. We rarely have someone buy a texture and not like it for whatever reason. Also, for every texture that we have, there are probably 50 that were not good as far as dimensions, spacing, and height. If we find one that is really good, we’ll make it, but we’re not just going to make something that’s a hex pattern just because it’s a hex pattern.

Q: You offer RailScales in another material, can you explain?

Derek Shelton, RailScales – We’re very proud of our G10 RailScales, but we realize they are expensive. G10 is an expensive material that takes longer to machine than other materials. It’s harder on tooling, puts off a cloud of dust that is bad for you, so you have to have more ventilation. That’s why you don’t see a lot of stuff made out of G10.

Recognizing that not everyone can afford our G10 product, we saved up our money and started looking into injection molding, which was a whole new frontier for us. Our molds and scales are all made in the United States…every once in a while, we get compared to other products whose description might say that they were designed in the United States, but what that means is that it was not made here. Our products are all 100 percent designed and made in the United States and always will be.

We also wanted something that could handle heat. It was very important for us to have something that would never melt. What we offer is a very, very high rated temperature material, and we were able to get our color palate right on with Magpul. It’s not identical, and perhaps one percent different, so it matches everyone’s furniture. It has the same 416 stainless hardware that we use on our G10 Railscales, which are MLOK nuts that we individually machine ourselves.

They cost almost a buck a piece to make, so in 3-pack, you’re getting nearly six dollars of nuts in there. So, what we are offering is still a very premium product in regards to quality, function, and material.

Q: Anything else you’d like to add before we wrap up?

Derek Shelton, RailScales – We’ve been in business since February of 2014, and this is the first time in six years we have had any sort of media proactively want to do something for us. At RailScales, we don’t give out free stuff to people. We are consumers ourselves. When a buddy in our industry makes something we like, we buy it. We don’t expect a discount, and we don’t ask for a discount.

We started that because what I hate is when I read an article praising a product, and then I go and buy that product and realize that what I purchased was just garbage. I then figure out that what I had read was really just a paid advertisement. We don’t want that. If I give a guy a set of free RailScales, then he’s probably going to talk good about them. I don’t want someone to talk good about us unless they actually believe it. It’s something I see a lot.

We’ve always said that one day, the time will come where someone will come and ask us for a simple, honest interview, and when that happened, we’d make sure to let that person know that they were the first. So, I want to tell you that this is our first interview.

We made that decision because we’ve chosen not to pay. We get approached, and we very politely say no. We get hit up daily by influencers on Instagram, and we politely decline. We just have to make sure that what is being said about us is honest and unfiltered.

So, thank you. We appreciate the interest. Props to ARBuildJunkie, and I guess, shame to the perceived “big” media out there.

###

“At RailScales, we don’t give out free stuff to people.”

Oh I remember that lol