With the recent launch of the Q Sugar Weasel, we thought it was a great time to again reach out to Kevin Brittingham for an update on that firearm, the new Q Side Chick chassis for the Remington 700, and an update on the status of the upcoming 8.6 Creedmoor. In case you missed our first interview with Kevin, be sure to check that article out here.

In part one of this interview, we’ll focus on the Q Sugar Weasel. Later this week in part two, we’ll discuss the launch of the SIDE CHICK and get an update on the ongoing story of the 8.6 Creedmoor.

Q: Kevin, the Q Honey Badger has continued to be very, very popular. It’s one of my favorite rifles, but we’ve now very recently seen the launch of the Q Sugar Weasel.

Kevin Brittingham: The Q Honey Badger was sort of an accident. We may have touched on this the last time we spoke, but we didn’t have intentions to actually do it. One of the guys who was with us when we started Q, he was a younger guy and he would talk about how the gun had such a following, yet it had never been produced. He would say to us, “you gotta build this gun!”

When we decided to do it, I really only thought we’d build like 500 of them. But the gun has just taken off. It’s been so, so popular for us. I don’t know how backordered we are now, but it’s substantial…especially with the pistol variant now available.

Q: You mention the backorder. Can you talk about the reason behind that bottleneck with the Q Honey Badger…is it due to the proprietary nature of the firearm?

Kevin Brittingham: The Q Honey Badger looks like an AR, feels like an AR, but it’s not. The only stock AR components are minor components like pins and springs, mag catch, and things like that. The Honey Badger bolt is also the same as a standard AR, but everything else, including the carrier is different.

Both the upper and lower of the Honey Badger are billet that has been machined to accept the stock…which is a totally different design than any off-the-shelf AR.

“Artificially Inexpensive”

Another thing people don’t realize is that the AR-15 is artificially inexpensive just due to the mass production of parts. We thought that would be helpful for something like the charging handle or the selector. But what we found out when we started producing in volume is that we were rejecting triggers, charging handles, selectors…because these small companies don’t know the actual M4 tolerances, or have the Technical Data Package or anything like that.

What a lot of small shops and small accessory shops do that build these components..they just have 5 or 6 ARs sitting around, and they test their parts in those. When they may make a component they look at it and say “oh, well it works in all of these ARs we have here…it must be fine.” But sometimes those parts don’t work in the M4 tolerance range. And that is what we started to run into.

“We didn’t want to produce triggers, selectors, mag catches or charging handles”

So our engineers started working with a lot of the vendors. But as you know, half of the employees at Q are degreed engineers. So, we’re a little different than most other companies. We didn’t want to produce triggers, selectors, mag catches or charging handles…or any of these components that people THINK are standard that you can buy off the shelf. We didn’t want to start making those kinds of things.

We wanted to innovate and make a new gun, but we also wanted to rely on certain components from other manufacturers. However, if we’re not doing the tolerance stack to where we know what the tolerances of the parts are, and those parts must properly interface with correctly designed mil-spec components like the receivers…then we have to control it. A lot of the vendors were very open to it and they understood.

Most of these small companies, they don’t have any engineers. It’s more like a “smart guy that has a machine shop.” So, most of them were open and they would allow us to redesign the parts to where they will work in everyone’s gun. That’s beneficial to the company and it’s beneficial to us because it saves us a lot of quality control time, us having to reject parts, having to go through all the RMA process with vendors and all of that kind of thing.

“They think that their parts are good”

That said, there are some vendors who are just not open to it. They think that their parts are good, and if it does not work in a Colt mil-spec lower, then Colt messed up. And that’s generally not the case. So, in those instances, we started designing and making and producing some of the standard parts. That’s what has led us further down this road to where we are now with the Sugar Weasel.

The bottleneck with the Q Honey Badger is the receiver and the stock. Those are also very expensive parts for us to make. I recognize that the gun is expensive. Also, a huge part of our customer base is half my age. $2,000 to $2,500 bucks is a lot of money to a young guy, or just a normal guy with a family.

“A tricky thing”

So, how can we get a lot of the benefits that make the Q Honey Badger so great in a less expensive package that we can produce in much greater volume and reach those customers? It’s kind of a tricky thing. There’s some guesswork involved, and it’s also risky for the business to some degree as we’re trying to build a brand that is quality stuff…and how do we do something that’s more “vanilla”? But that’s the way you get the price down.

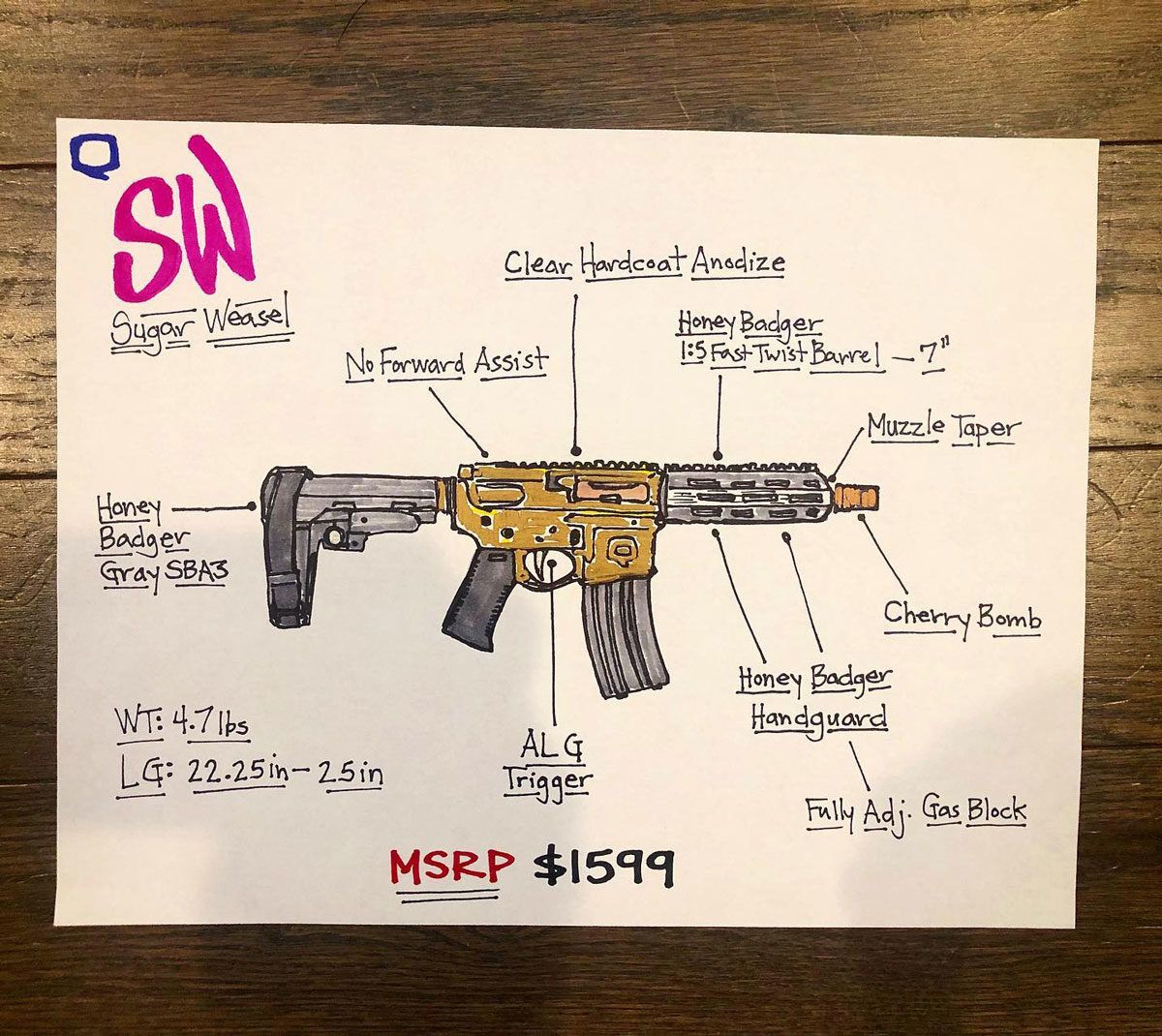

Q: Can we touch briefly on some of the ways the Q Sugar Weasel is different?

Kevin Brittingham: First off, we did forged upper and lower receivers for the Q Sugar Weasel…and what it is, is basically “the poor man’s Honey Badger.” The forged upper and receivers that are “mil-spec”, but they’re not. The tolerance ranges are, but we removed the forward assist because we don’t use it.

We clear hard coat the upper and lower of the Q Sugar Weasel so that it is the Honey Badger color and it’s not a lesser finish by adding pigment to the anodizing process.

We use a standard M4 Buffer tube…It’s also standard “mil-spec” but then again it’s not because we clear anodize them. That’s so you can run an H2 buffer or whatever buffer you want.

It comes with the SB Tactical SBA3 brace that’s in our Honey Badger gray color.

Then theres details like the charging handle. I actually like the mil-spec charging handle. It’s what I grew up with and learned on. The Radian one on the Honey Badger is awesome, but I don’t actually use the ambi part of it, so I don’t particularly care. But that charging handle was just another expense and a lot of people have their own taste when it comes to that, so we use a standard one, but with a clear hard-coat.

Other than that, all of the features that make the Honey Badger awesome – the light weight, the fast twist barrel, the adjustable gas block, the Honey Badger hand guard…all of those things we left in the Q Sugar Weasel. And for hunting and things like that, those are the things that are really critical.

With the fast twist 1/5 barrel, you’re going to get the best accuracy available out of subsonic projectiles and it gives you more energy with supers and subs because you are getting a rotational energy that does have an impact on the target. it’s not necessary for Joe Blow who is going to go out there and shoot 50 feet, but for the guys out there like me who have a farm, and they shoot pigs and they hunt and stuff like that, these little touches make the gun better.

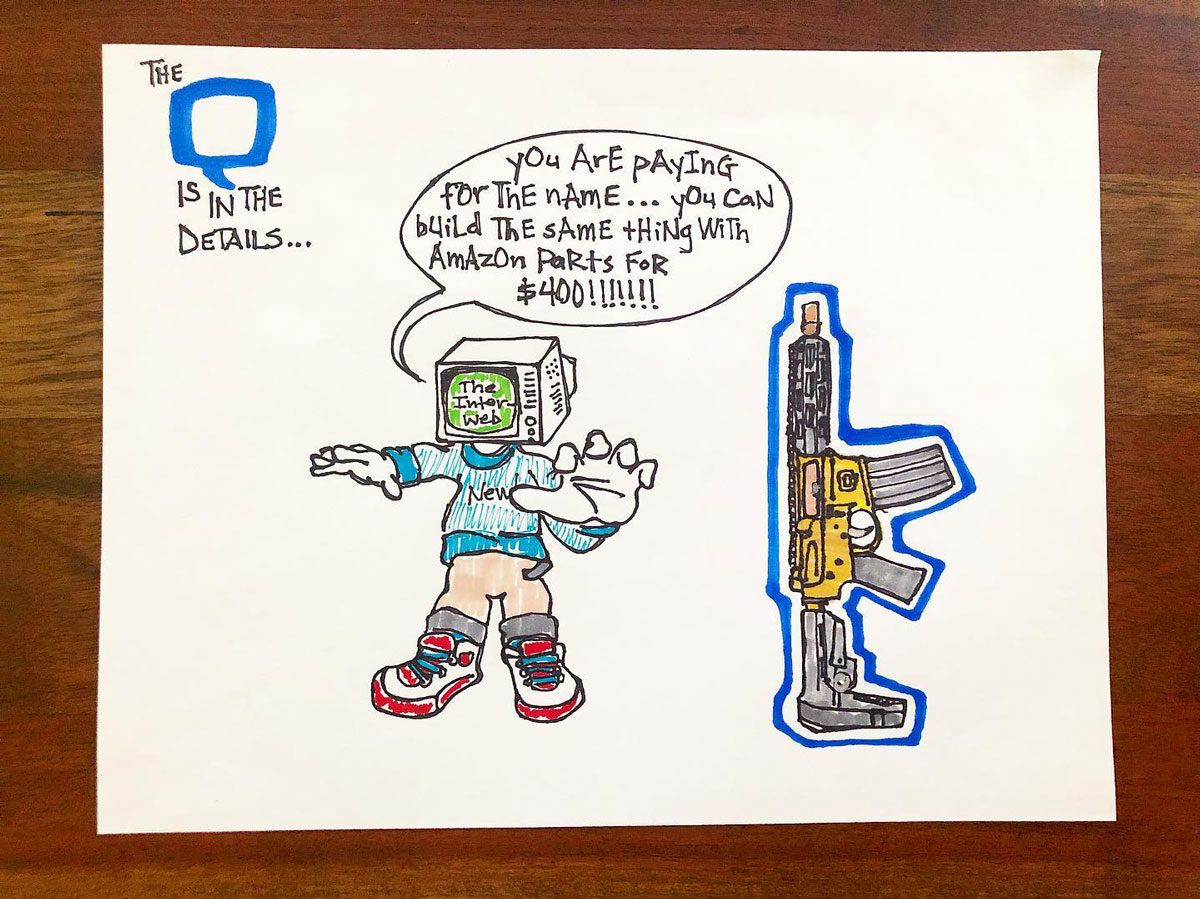

Q: I’ve heard some folks claim that they’re simply going to build their own Q Sugar Weasel equivalent. Can you share your feelings why the Q Sugar Weasel or Honey Badger is worth considering over doing something like that?

Kevin Brittingham: You can get parts guns to work. But they are not going to be as reliable as what we’re doing. Everything with the Q Sugar Weasel is held to the same tolerances we do with the Honey Badger. And then making every component ourselves…we know that they interface correctly. We know the tolerances and we QC the individual parts.

It’s fun to put ARs together. I see how excited people get when they come here to do the customer build days and they get to build their rifles at Q. But when you get the parts in, you don’t know if those are out of spec. We just rejected 1,000 bolts carriers from the biggest bolt carrier producer in the country because they were out of spec.

“Stuff Happens“

They were out of spec in a very critical spot, in the bore where the bolt is…and the guns were not functioning the way they normally do. There was gas leakage. Now can you imagine how long it would take for someone to know what that was? You’d be there thinking “oh, I need to change the rings on the bolt” or something. And again, this is from the oldest and biggest bolt carrier producer that there is. That stuff happens. But when you order just a bunch of parts and put them together, you don’t know the tolerances of the components. As such, you don’t know how reliable that gun is going to be. And that’s part of what you get with us.

Looking over the gun, there’s a lot of little details on the Q Sugar Weasel that you don’t see on a lot of guns out there…

Kevin Brittingham: For sure…another thing you get is that attention to detail. With the Q Sugar Weasel, You still get the muzzle taper. You still get the Cherry Bomb…There’s all these subtleties that make the gun good. Again, it uses the Honey Badger barrel. So not only do you get the adjustable gas block, but we’re not pinning that in place. We use a jam nut, and that helps to seal the gasses better, so you’re going to get better reliability. The other benefit is for the user. That’s because we have a simple tool where you can remove that and change out the gas block, change out the barrel…you can work on the gun easier.

“Build the most innovative stuff”

Can you build a cheaper gun? Sure. Could I build a cheaper gun? Yeah, I mean I could fire all those engineers and save all that salary and we could just produce guns. However my company is one that wants to build the most innovative stuff. Thats a long road…But, I think we’ve proven ourselves with the Honey Badger, the Fix, and now with something as simple as the Sugar Weasel.

But people will look at the Q Sugar Weasel and the Q Honey Badger and say they can build that gun…that they can buy those Maxim Defense three pound stocks and put them on their gun and say its same thing. It’s just not. You can build a gun for $600. But there’s a lot of companies out there like Barrett or Knight’s Armament that do a lot of what we do…now go price those guns. They’re expensive…and it’s not to buy Chris Barrett a new Ferrari. It’s expensive to do things correctly.

Firearms are certainly an area where people sometimes don’t realize there are differences past the exterior..they don’t “look underneath the hood” and see what’s going on.

Certainly a lot of people…they think things are the same. There’s a kid at work with me who has an F-150. I have a Raptor. They’re not the same truck. They both say Ford…they are both F-150s technically. It’s not the same. Anybody who does any off-roading knows that.

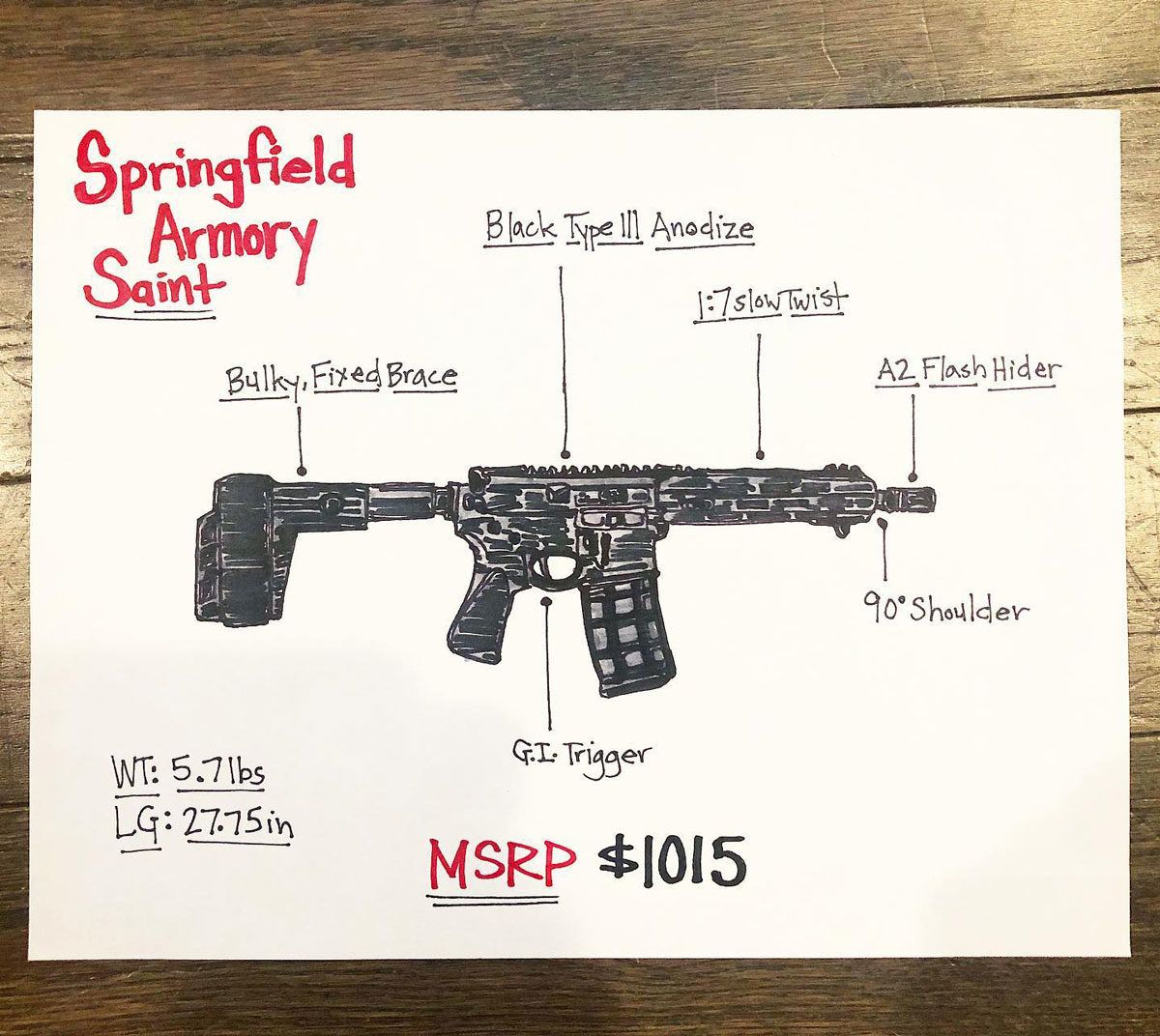

If you don’t care about this level of detail or quality, I get it. Or perhaps your budget does not allow for it. It costs me more to produce the Q Sugar Weasel than something like the Springfield Saint.

That Saint probably does not cost them a lot of money to produce…our margin or our percentage is probably the same. But, theres’s the idea of things being equitable…We need money to stay in business. So, you can appreciate the innovation we do, or you don’t. If you appreciate it, you support it.

From what I’ve gathered, the launch of the Q Sugar Weasel seems to have gone well…

Kevin Brittingham: In the 24 hours after we put it on the website for retail, we sold 600 of them. It was exciting too as it was the first gun that we had in stock when we released it. The Mini-Fix in .300 Blackout will be the next.

But back to your original question about someone building one, I don’t take it personal that someone believes that they can build a Q Sugar Weasel or a Honey Badger for $600. They’re just wrong. I would pay the extra $500 dollars…maybe more, just to get the 1/5 twist. But that’s because I shoot stuff with subsonic at distance. Not everybody does that, and that’s OK.

But if you go with a shorter barrel, you need a faster twist than 1/7 or 1/8. It’s just the way it is. Can you get by without it? Sure you can. And if you’re just going to the range and are shooting 50 feet or something, it’s probably going to make no difference. However if you want a gun that can be accurate with supers and subs, deliver energy, is going to be reliable and you want something you can be proud of…well, then the Sugar Weasel is a good value.

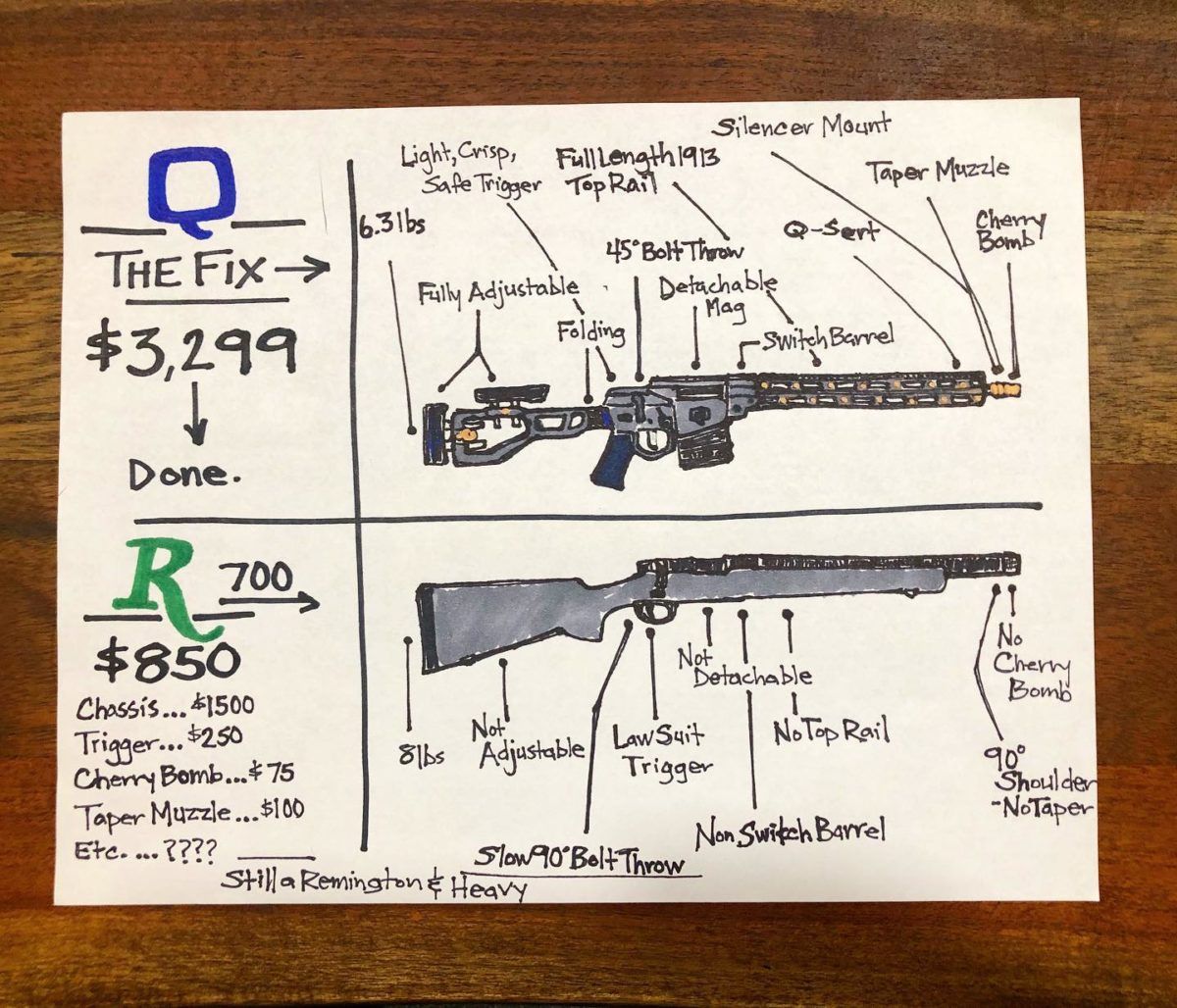

Q: I think many people look at the Fix the same way…but it’s become THE go-to for quite a few folks I know who use guns like that professionally.

That Fix rifle is around $3,200. Any gun store in America that has one, that is the absolute best value in that gun store. I know how many of millions of dollars it took to develop that gun. I know what it took. There’s a reason no one else it doing, and that’s because it is hard. The gun is innovative in every reasonable way…In every way that makes the gun more usable, in a way that is strictly focused on the user. The gun is complicated to produce. That’s why nobody is doing it. It was complicated to design, even though there is a lot of simplicity in it.

“It isn’t different for the sake of being different”

It was certainly not the best business decision if I’m thinking about “right now, how much money can I make based on political cycles?” But that’s the cornerstone of our company and I think it’s a great demonstration of our commitment to deliver innovation and delivering something different to the customer. But it isn’t different for the sake of being different. We’re not going to paint things weird colors and skeletonize shit.

When you look at the Q Sugar Weasel, it’s a pound lighter than every other gun that’s in that category that’s on the market. That doesn’t happen on accident. That does not happen because we cut the mag well out of it or some silly shit like that.

Q: Hows the backorder situation with the Fix right now?

Kevin Brittingham: We are close to a year backordered right now on that gun. It’s not an easy gun to produce, but I’m more concerned with the gun’s quality and the idea that every gun that ships out is better than the one before and that we are doing a better job with QC everyday. We have a commitment to that with our culture. People don’t quit working at Q…it’s a great place to work, and we have a culture there where everybody wants the guns to be the best.

Q: The Fix is another gun where you hear grumbling from time to time that they could do it better…perhaps not actually having used it in the field or on hunts. The gun has been phenomenal in our real-world experience.

Some people say the gun is too expensive. They’ll say you can just put a chassis on a Remington and have the same gun for like $1,200. That is so dumb…and you can’t. The gun is completely different.

In the end, we appreciate all of the customers. However, if you are not going to buy one of our guns unless it’s under $1,000, I don’t want your business and I don’t particularly care. You’re not our customer. There are companies for you, whether that be Savage, or Springfield Armory, or Spikes Tactical, or whoever those companies are. It’s just not what we’re doing at Q.

Q: Before we move on to the Side Chick and the status of the 8.6, I’d ,love to know what supersonic .300 Blackout are you using now? I’m still using a lot of Barnes 110…

Kevin Brittingham: When I sold Advanced Armament, the next purchase by Freedom Group was Barnes. I was a big part of that because I loved Barnes projectiles…The Barnes 110 bullet is phenomenal.

My only problem is Freedom Group or whatever they’re called now owns it. Barnes was loading their own ammo and the ammo was great. They were doing it in-house. But then one of the Remington geniuses decided it had to be loaded at the Remington factory.

And, so three years ago…I think I said this in one of my podcasts, during hunting season, I bought some Barnes 110, retail. Well, one box of 20 that I purchased had three different primers in it. So, you just can’t trust them. I don’t buy ammo from Remington anymore. Their quality control is shit and I just don’t deal with it. That said, I will get Barnes bullets and load them.

Hornady sponsors my hunting now, and they hook me up when I’m going to go shoot cool stuff. They have a GMX 110 that is probably just as good…I’ve killed stuff with it, and Hornady’s loading is much better. Is the projectile much better? I don’t know, but it’s effective and I trust Hornady’s loading a lot more. I don’t have primers fall out, and it shoots good groups.

###

Look for part two of our interview with Kevin on the Q SIDE CHICK and the status of 8.6 Creedmoor later this week.

Wow, for all the hot air placed on describing how reliable the Sugarweasle is, you’d think out of the box you could shoot at least a 20 round magazine through it without light strikes every 2 or 3 rounds! Yeah, unfortunately there are Sugarweasles in addition to mine, that’s right, not just mine that are so unrelaibele its pathetic for the price and all the hype placed on how great they are. Yeah, they are certainly cool (thats why I bought one 7 the Thunderchicken) but not that cool apparently. The factory even shipped a new hammer spring and it… Read more »

Wow this guy’s is full of himself. He makes the best everything even ammo. Nobody can come close to building a rifle as good as what Q is putting out. I like how he mentioned a few companies like Spikes like they made trash. He’s so full of shit, I don’t see how he walks around all day with a head that big lol. They might produce nice rifles but you can still build a rifle for less that’s just as reliable and accurate. If you don’t think so go ahead and overpay for a honey badger I’m sure you’ll… Read more »

Are you still poor?