“MIL-SPEC equals lowest bidder” … “Military issued? I don’t want it”. There are a large amount of people within the firearms community who express these sentiments, without fully understanding what they are saying. They do this as a way to immediately denigrate and dismiss a firearm or piece of equipment.

The most recent time these sayings have come out is with Sig Sauer releasing the M17 military surplus commercially. Many online immediately discounted the pistol due to the simple fact that it was issued to the military.

These commenters had no knowledge of how long, and how often they were used. More importantly, they likely had no idea of maintenance schedule, nor any of the things that actually indicate a firearms’ quality.

On some level, I understand the sentiment. We see the HWMMV’s break down, we see weapons have malfunctions, and we see old night vision equipment have issues. Yet, what we don’t see is that operator of that broken down truck neglected to check the oil. Meanwhile, yet another operator just finished running his identical truck for three days straight without issue. We also don’t hear about the M2A1 .50 calibers that fire in -20 degree weather because they have been provided correct lubricant and care, or the Beretta M9s that fired 15,000 rounds before the locking block finally broke.

My point is, any piece of equipment needs a knowledgeable operator, as well as someone to maintain it. In the military, we find that some over-clean, and on the opposite side of the spectrum, there are some who never clean. They certainly don’t inspect often enough, and they definitely don’t write up their bad parts for replacement or repair.

Because we tend to focus on the negative, today I believe that many of the people who are using the term MIL-SPEC as a pejorative, simply don’t understand what MIL-SPEC really means. Nor do they understand all that goes into the military’s acquisition process.

What does MIL-SPEC really mean?

So, just what does MIL-SPEC really mean? Simply put, it means that there is a standard in place. In this case, a military standard (MIL-STD) or military specification (MIL-SPEC) acts as a way to ensure consistent reliability across a multitude of equipment.

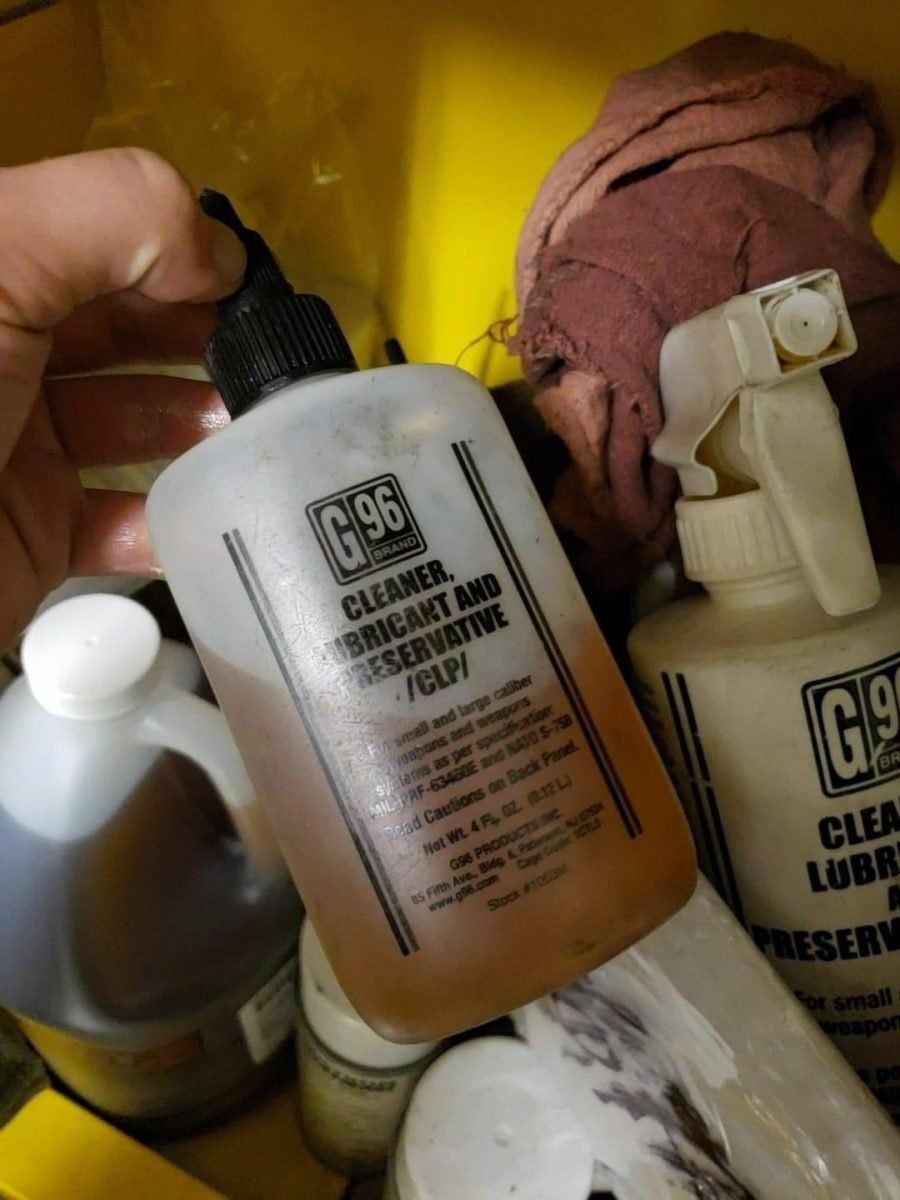

Everything has a standard, even magazine pouches. The cleaner, lubricant, and preservative (CLP) we use states “MIL-PRF” on it, which means it’s a “performance specification.”

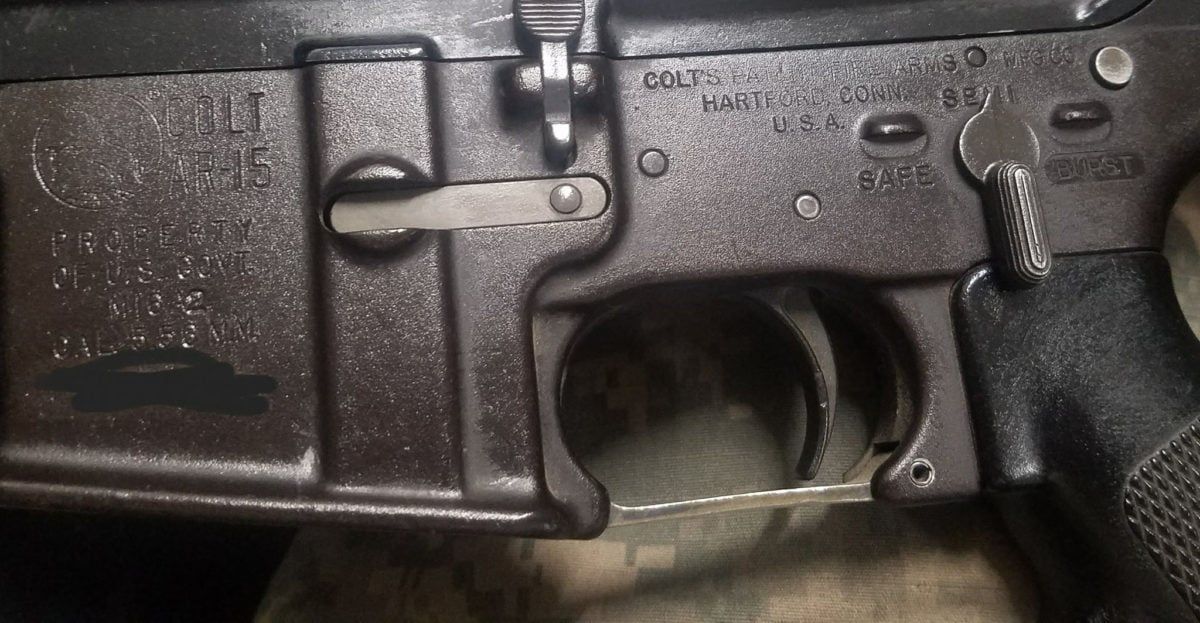

The largest standard that we see within the AR world is known as the TDP, or “Technical Data Package.” The TDP was something created by Colt which states proprietary information on their rifles. This means size of gas port, length of springs, etc. This TDP became THE standard.

Will Larson was renowned for teaching TDP, which is why so many loved him and Semper Paratus Arms courses. He taught about what kind of weapons you could trust and why.

Since the TDP was first bought by the Army in 1967, enough information has gotten out so that many AR part manufacturers now follow it. In order for them to do so, it does require good manufacturing equipment, and the funds to keep their equipment running at a high level.

Colt went so far to honor the standard that they made sure to replace machine equipment parts at regular intervals to ensure every firearm component was cut correctly. Colt did this because they had contracts to uphold. As such, they needed good quality assurance on the AR parts they manufactured.

On the flip side, it’s important to understand there are manufacturers in the marketplace who don’t seek to keep or maintain a basic standard of quality. It’s an unfortunate fact that some manufacturers skimp on their parts. Often these subpar parts find their way back to the manufacturer as returns…They are sent back because a company did not want to use them.

Do you know what happens to those substandard parts, though? As it turns out, they are not put in the dumpster. Instead, that manufacturer will offer these subpar parts to other less demanding companies who will buy them, and then turn around and sell them to end users cheaply.

This is unfortunate, as buying quality parts matters. Standards matter. Over and over again, I’ve seen how build quality matters, even on something as small as a selector spring detent. There are detents going around that have a flat tip that seats in the selector, instead of a pointed tip.

When someone searches online if this is acceptable, they will quickly learn that Colt’s detent features a pointed tip, and it does so for good reasons. Colt trued their weapons, which is why they are so highly relied on…yet there are still parts out there being used which do not meet standards, and can easily degrade and cause malfunctions to the weapon system.

Research and Development

People who have negative opinions of MIL-SPEC and of the firearms that are used by the military also do not always seem to grasp the amount of work that went into ensuring that the weapon is viable. The fact of the matter is that very contract put out by the military to be fulfilled has very specific specifications that must be met. It can be anything from the length of the flash hider, to the amount of rounds fired without a malfunction.

Companies go to great lengths to create a weapon that falls into the specified categories and wins the contract. A lot of time and money goes into the research and development of said weapon. Much effort and funds also goes into demonstrating the weapon’s performance, and then making absolutely sure that performance is maintained.

Finally, when a new piece of equipment is issued, there will be classes given to both operators and maintainers on how to operate and care for that piece of equipment. There are also things called “Modification Work Orders” (MWO). These come out throughout that piece of equipment’s life as new parts are released that can help the performance of the weapon.

In all my experiences with military issued weapons, I have seen firsthand how beaten and trashed our equipment can get in the military. It is used roughly and often. I have also seen firsthand though, how reliable it can still be if properly maintained. The bottom line is I have no problem gaining a firearm that has been so trued and maintained like they do in the military.

The first few years working full time for the Minnesota Army National Guard, I was able to see every unit within the state, and witness first hand how poorly some weapons were maintained. However, after by visiting each unit once a year, doing preventative maintenance, and also instructing each unit on where they were lacking, we soon saw the condition of the equipment dramatically improve.

Military issued equipment means that there is a standard, and if that standard is maintained, it will save operators lives, just like your individual weapon could save yours or your loved ones.

###