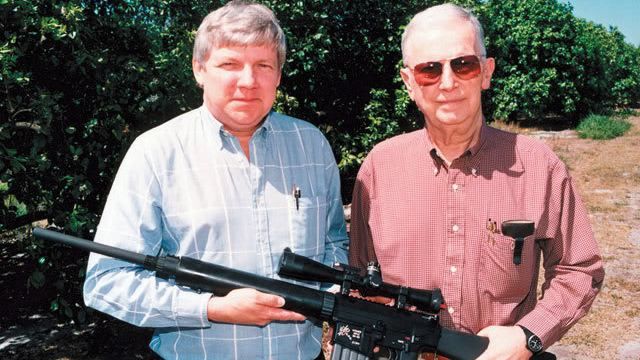

Jack Leuba, Knight’s Armament’s Director of Military and Government Sales, challenges you to find a rifle that can overall outperform their SR-15/SR-16. In my experience with these rifles, this is not boasting or hyperbole.

Knight’s Armament is on the short list of the world’s greatest firearms manufacturers, but their ability to create such quality firearms is much more impressive if you consider everything else they take on…all at the highest level possible. They’re perhaps the premier one-stop shop for a wide variety of innovative, rugged and reliable accessories, suppressors and optics.

We reached out to Jack Leuba to learn more about the company, where its been…where it’s headed, and have him explain just why its products are worth the premium price.

Q: Jack, thanks for taking the time to give our readers a bit of insight into Knight’s Armament. Can we start with a bit of background on who you are and how you ended up at KAC?

A: I did 16 years with the Marine Corps in various positions, but I was an infantryman by trade. After being around the block, I came back and I wanted to go be an instructor for high-level marksmanship. I went to Quantico and worked at Small Arms Weapons Instructor Course. While there, we were tasked with the revamp of the Marine Corp Rifle Marksmanship Program. From there, I bounced over and I worked with the British Royal Marine Commandos as their marksmanship and CQB liaison.

Joining Knight’s Armament

After that, I did another tour in Afghanistan. Once I finished that, I realized I was going to be happier pursuing something outside. So, I started into consulting. Then, I heard about an opening at Knight’s Armament. I was really familiar having used their guns, and I had been a fan. What really got me was the M110K1 when it was adopted by MARSOC. It was a new face for Knight’s and I really liked it. So, seeing an opening, I started at Knight’s Armament in 2012, and I’m currently the Director of Military and Government Sales.

Q: Knight’s Armament is known for quality…but also innovation. Many companies claim that, but Knight’s really walks the walk while always keeping a fairly subdued profile. Can you talk about where that company culture comes from?

A: Knight’s Armament really started proper in the mid 1970s, doing small projects but even then in the early days, it always evolving forward. The next level really came when Mr. Eugene Stoner came to work with Mr. Knight on his vision of bringing the AR-10 back as a commercial product. At the same time, even then, there was work being done on machine guns, and suppressors.

You can also go back to around that time and see really early handguard and accessory rail stuff from Knight’s Armament before anyone else was even thinking about it. Mr. Knight had the idea from watching soldiers in Grenada running around with items literally duct taped to their M16A2. He said there has to be another way to do this…so what is it?

At the time, the only thing he was really thinking about was a flashlight. But, when he shopped his ideas around, no one knew what he was talking about or even saw the need.

Being Where No One Else Is

So, Knight’s Armament was demonstrating that forward thought process we’re known for even then….asking: what is this, and how do I make it better? Mr. Knight would always search for the better path, even if people didn’t always get it at the time. Now, others not “getting it” is no fault of their own…you have to understand that many people look at the bigger picture of their jobs and don’t focus on the minutia. But Mr. Knight has always had a passion. And you look at a lot of the things where Knight’s Armament initially gained leverage, it’s in areas where no one else was.

What we do is today is no different and it’s a critical part of the Knight’s Armament design philosophy. We identify needs before others do and then refine what we design through interactions with high-level performers.

For example, when Knight’s Armament won the M4 RAS, there really wasn’t any other attachable handguard system for an M4. You can look at it now and say it’s outdated, and it’s true there’s been a lot of progress in this area with us, but there wasn’t anything else then that was even close. It’s now been on guns for the past 20 years. Virtually my entire career, the original M4A1s had the M4 RIS on them.

Q. Many look at Knight’s Armament and think primarily rifles…but the company is much more than that. You also offer optics, suppressors, and many other items…it’s sort of a one-stop shop. Can you explain that to our readers?

A: Looking at us a one-stop shop…I think that’s exactly it. I don’t need to worry about “will this suppressor work with this barrel, and this gun with this handguard with this Knight Scope.” It’s all right there, in-house, tested together. It is built as a system together.

That’s one of the huge advantages that we have. We have such a broad capacity and such a broad product line. However, while it’s great to have that…it cuts on the other side

Knight’s doesn’t just get to be very good at suppressors…just be good at barrel manufacturing, just be good at machining…we also have to be good at ergonomics and thinking outside of the box with everything we do…and then have the time, patience, and resources to test it all and see if it works or not.

Q: One of your products that has just worked for me for years is your NT4 suppressor. It’s pretty legendary at this point…it really influenced the entire industry.

A: I could talk about the NT4 all day. It’s one of the things that even today, its 20 years old. It doesn’t seem like a lot, but think about how much technology has changed in 20 years. Look at everything around us and look at how many suppressor companies have come and gone in 20 years…it’s incredible.

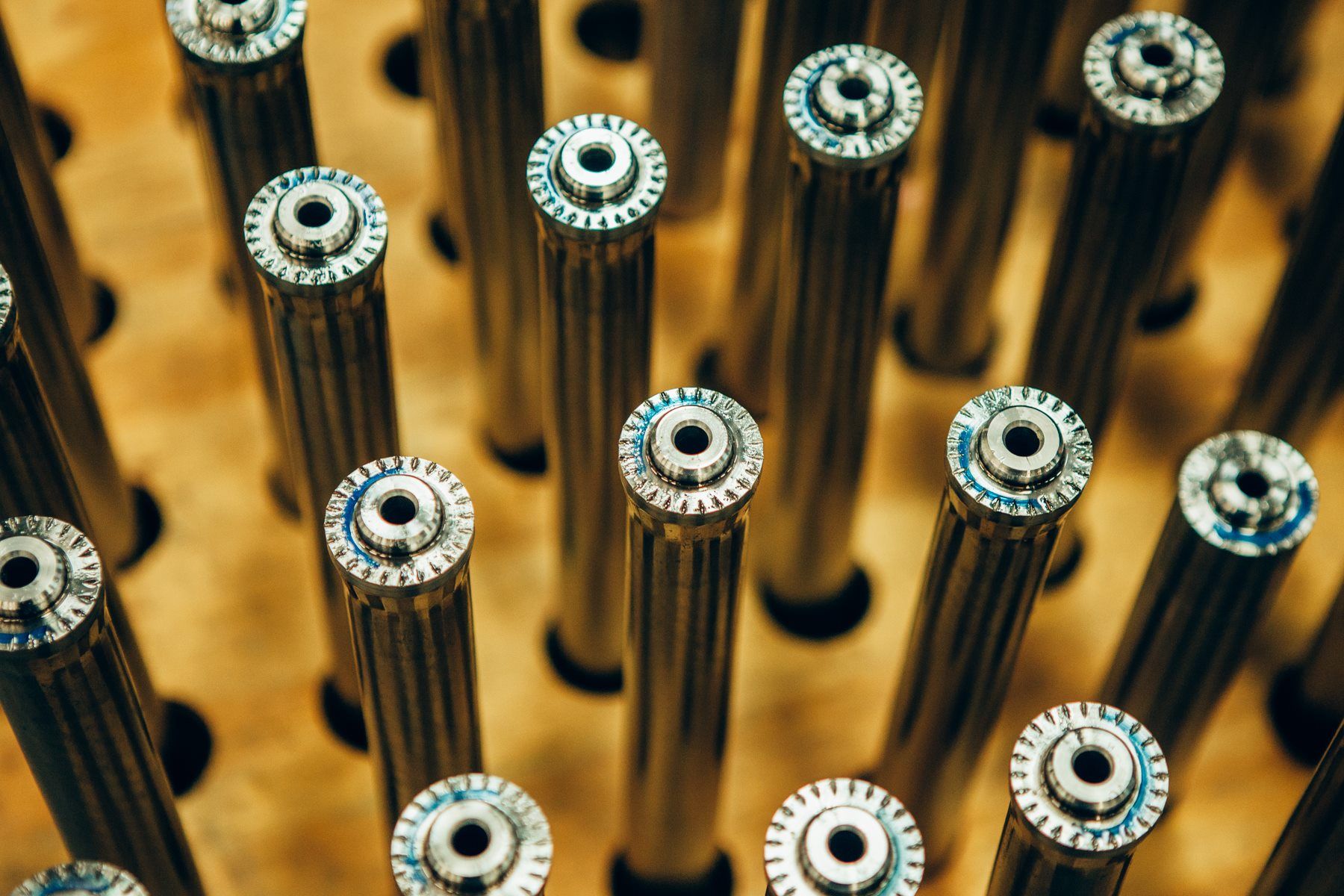

When you look at it, it has one of the original QD style attachment methods…attaching to the muzzle device. It’s also just incredibly durable. I can’t even tell you the amount of NT4s that we’ll bring back from a place…someone will say “yeah, this one is dead”….or ones that are 1033’d that will come back to us. You’ll see they’ve been in the system for 15 years.

We get them back and cut them in half to see what’s going on, and it’s literally just completely full of carbon and copper. They probably have 50,000 rounds through them and they’re still hanging on.

People say all the time “it’s a dinosaur.” I say yes, it might be a dinosaur, but it’s a T-Rex. It’s THE dinosaur. When it comes down to it, and you look at the NT4 and you compare it to other suppressors, it strikes that perfect balance of being good enough at enough things while being super durable.

Q: You’ve released some new suppressors which are similar to the NT4 but differ in regards to attachment…In my use, I’ve found these cans to be just as rugged and high quality.

A: The biggest thing with our QDC suppressors is they isolate the attachment mechanism from gas flow, so you have a far reduced issue with getting suppressors on and off after some pretty consistent use. They’re also tough. You look at the 762 QDC and it’s basically an NT4. They are built with the same mentality of durability and robustness. We want the suppressor to be lasting at least as long as your barrel. When it comes time to throw them away, it should be because you literally shot them out and it’s gone through a gun or two.

Q: Every year, one of my personal SHOT Show highlights is what is coming from the Knight’s Armament booth. Can you talk at all about the process by which new products from KAC come to market?

A: The true vision of Knight’s Armament is Mr. Knight’s. He’s still in the office day-to-day and has his hands on every item that goes through our system and comes out the end as a finished product.

Mr. Knight is always looking at everything going on and asking: How can we do that better? What doesn’t this do well? What doesn’t this do right? How can we fix that?

Mr. Knight is involved in every project that comes through Knight’s Armament, whether it’s a suppressor, a Knight Vision scope or a bipod foot.

If he wasn’t the one who came up with it completely originally, he’s the one who saw a tweak to be made to make it better than what the thought process was by the engineer, or by the user who originally had the need.

I can’t tell you the amount of projects I’m working on where I have something in front of me and he’ll come in and ask: What it is? What does it do? Who are our competitors…and is it better? And if it’s not better, he will want to know why we’re wasting time with it. If it’s not better…if it does not outperform, and if it’s not in the top three of anything, we’re simply not going to chase it.

Product on Request

Another great thing is pretty much every product we make or have made is based on a program requirement. Very few things other than perhaps a rail cover is something that wasn’t pretty specifically written out as a requirement. There was something that

Finally, I’d mention that at Knight’s Armament, we are constantly striving to make everything better. There’s a constant evolution path. There are very few things where we ever say “yep, that’s done.”

Q: Speaking of evolutions…I’ve had Knight’s Armament SR-15 IWS, a Mod1 and now a Mod2. I’d like to talk a bit about the Knight’s Armament SR-15 line of rifles and why a shooter might want to consider one? There’s some things internally that these rifles do differently than other manufacturers in regards to bolt design and gas system. While other rifles look similar, these rifles feel quite different in hand and when shooting.

A: It’s almost hard to find a bad manufacturer right now. You have to go out of your way to really find the cheapest of the cheap and not get a decent AR-15. There’s a litany of good manufacturers out there that put a lot into what they do, and they are coming out with some good, creative stuff.

You can go out and source really roughly equivalent stuff to some of what we’re doing, but there’s certain things you are just not going to be able to find anywhere else. For example, you cannot get a better bolt than what we have in our gun. It just does not exist on the open market.

There’s a bunch of good cold hammer forged barrels, but there’s not many that have a gas system that so specifically controls your gas flow and works so efficiently across the band of decent ammunition types. It’s going to be very hard to find a gun that has been built and tested to ensure it works suppressed and unsuppressed…and not just with one suppressor, but with a whole family of suppressors.

Also,

A Knight’s Challenge

I challenge anybody out there to find a rifle that’s is going to outperform us in every category. You might be able to find a gun that is marginally more accurate. You might be able to find one that’s a little bit lighter…but when it comes time to put everything together into a gun that shows up at your FFL that you don’t have to mess with…well, I don’t know. I don’t know how much that’s worth. We’ve got a price tag on them. It’s a question of what’s it worth to you? What’s it worth to have a gun that you can look at and know that gun is going to work for 20,000 rounds?

If I buy the cheapest ammo, I’m going to have to invest 10,000 dollars to break that thing…Knowing that if anything ever goes wrong and that gun isn’t doing what it’s supposed to do and you’ve been doing what you’re supposed to do to take care of it, that it’s backed by Knight’s. That’s a strong challenge, I think.

Q: Can you speak about what the future holds for Knight’s Armament? Overall trends you see in the years ahead?

A: Of course there’s trends we see like 300 Blackout, .224 Valkyrie, 6.5 Creedmoor. Those things are really interesting to us, but it comes down to what is the user…what is a government buyer looking for? What high-performance item do they need but not have?

As far as what we’re working on…we’ve been doing machine guns for awhile…we look at lighter weight, shorter barrels, better performance. It’s all about capability. We ask: What is the capability gap? What is there to be exploited?

We’ve got all kinds of programs and projects in-house…mostly government, but it’s about what new technology will make this new thing do something better than something bigger? How can I match or exceed this capability with a lighter shorter, faster, quieter system? That’s where Knight’s Armament is going.

Shorter, Faster, Quieter

Suppressors are another huge thing. We’re always asking “how do we improve that gun/suppressor integration to get the absolute best performance?” A benefit there is we truly build suppressors for our guns and our guns for our suppressors. By keeping everything in-house and keeping everything tight, we can do things with systems that other manufacturers simply aren’t able to do beyond the conceptual phase.

And really, at the end of the day, all of this benefits not just our Soldiers, Marines, Airmen, Coast Guard…folks that deserve the best, but also the American buying public that deserves the best. You have a place where you can get the best…and it says Knight’s on it.

Tremendous thanks to the staff at Knight’s Armament and to Jack Leuba, Director of Military and Government Sales for taking the time to speak with ARBuildJunkie. Visit them on their website for more information.

Question. Need help. My kac 14.5 i just got with a few hundred rounds already through it keeps having FTF. No rime or reason and no round count matters. Could be at 2 or 6 rounds in. The first round always works and the bolt locks open on the last round. Using pmc .223 And Speer gold dot tried all different kinds of mags used plenty of geisslie grease lube. Stock recoil spring with KAC buffer. Geisslie ssp trigger (hammer spring is in correct on top of the roll pins. I looked at my KAC 16in Upper to compare firing… Read more »