FM Products…a.k.a Foxtrot Mike Products has built a 9mm PPC that is making waves in the industry. The firearm has a unique design which its designer says addresses problems inherent to most PPCs. To learn more, we reached out to that designer…FM Product’s Paul Noonan. He spoke to us about his unique background, common PPC issues, and why the FM Products FM 9 is worth considering if you are looking for a reliable and affordable pistol caliber carbine.

Q: Paul can you walk us through how FM Products came about…and a bit of your background?

Paul Noonan, FM Products: I’ve been doing firearms design and engineering for about 10 years, working for other companies behind the scenes. Some of the more recent stuff I did was the BR-180 and the Retro Rifle line for Brownells. I did the EDC X9 and the AR9 for Wilson Combat, which was a very well received handgun…just a bunch of stuff like that.

So, I don’t think I’m a traditional firearm engineer or designer. My background is in manufacturing. I started out as a machinist for about 20 years. Before I was an engineer, I had a love of firearms and I just kind of fell into it.

I had been making small parts for my own guns, and then they started getting out into the world. People began to contact me when they saw what I was making. From then on, my phone just started ringing off the hook…and it was pretty much like that for 10 years. I never had a dull moment.

I don’t think I’m a traditional firearm engineer or designer. I’m kind of an idiot-savant when it comes to machining aluminum. That’s just something I’m really good at, and because of that, it allows me to save money manufacturing items and pass that savings on to the end user. That’s really what it boils down to…the better machinist you are, the shorter the cycle time, the less the parts cost to produce, the better product you are able to get to the end user for a better price.

Q: Can you talk about how the FM9 came about?

Paul Noonan, FM Products: I’ve got an old friend who has more money than sense than I do and always wanted me to start my own thing, so we developed the FM9 about five years ago. We then tested it for two years, taking all the things we had learned from the seven or so 9mm carbines that we had developed previously for other people. We ended up patenting a bunch of stuff.

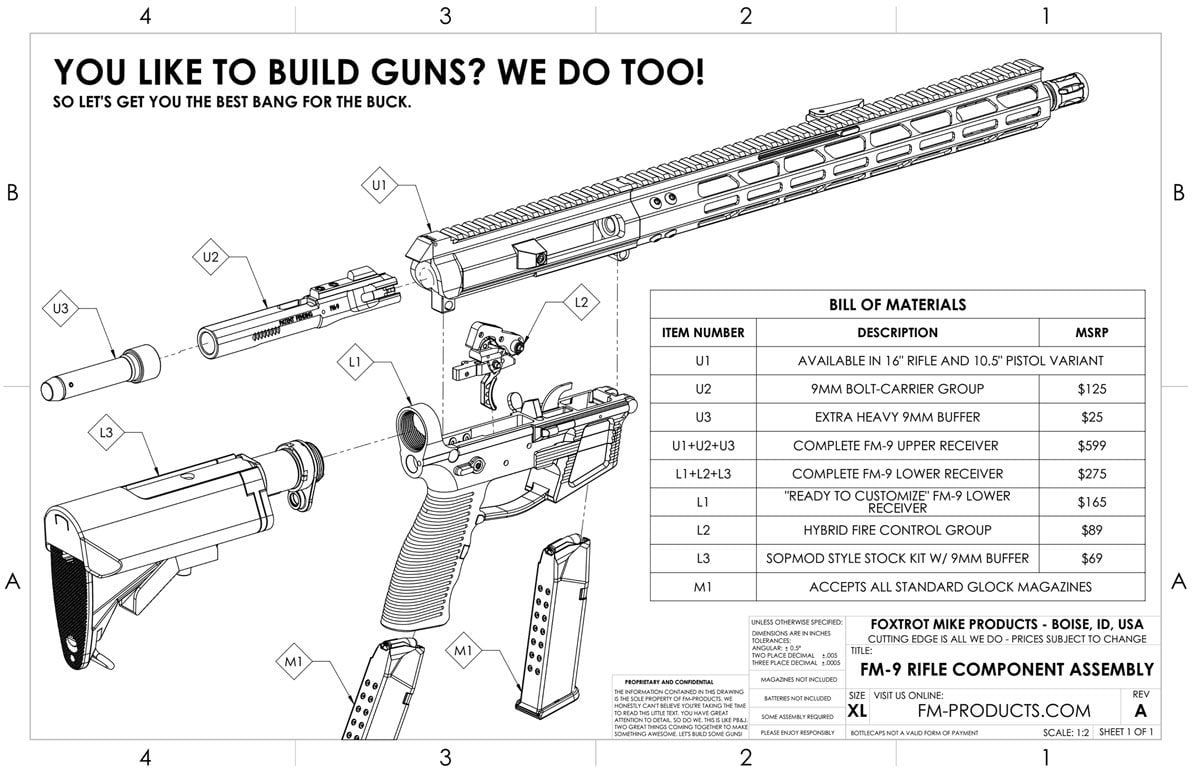

As far as features of the FM9, it’s got a pretty elegant, patented bolt hold-open that is not based on bent sheet metal. It also has a forward charging handle that lives in an ergonomic position on the handguard. In other words, if you needed to utilize the charging handle, traditionally the manual of arms would require you to point the barrel at the ground and pull back on the charging handle and lose your aiming point. This will allow you, with your weak hand, to manipulate the charging handle.

Q: Can you talk about the reception the FM9 has gotten?

Paul Noonan, FM Products: We brought the 9mm carbine to the market and it’s been pretty well received. I think a lot of that stems from us making a lot of the stuff in house, sparing no expense on the quality of materials for the product. So far, we’ve had a great deal of success. It has certainly been a great transition from being behind-the-scenes doing product development and firearms design for other people, to now doing it ourselves.

Q: What was is about the 9mm PPC that you felt needed to be improved on?

Paul Noonan, FM Products: There are a few issues, some of the most common we see are problems with feeding, issues with the bolt hold open not working, and burst fire.

Q: If you don’t mind, can we go into some more details on each? Let’s start with feeding, why is that an issue?

Paul Noonan, FM Products: Ultimately, there was an inherent flaw in the designs that everyone copied initially. When people veered away from the Colt and they started to do a Glock receiver, they thought “if I put a Glock magazine in an AR lower and position it in the same position as a Glock handgun, it will work.” And 95% of the time that is correct.

The analogy for me is, it’s kind of like the way you train dogs. Years and years ago, someone would kick their dog and 10% of the time, they got results. Well we don’t train dogs that way now. If a dog pees outside, you say “good boy.” If he pees inside the house, you don’t say anything. The same holds true with this. What people failed to realize is the reason it works in a Glock handgun is because the barrel tilts. As the barrel tilts, the bullet goes straight into the chamber.

9mm PCC Feeding Issues

Ultimately, the feedback you see about all 9mms is there are feeding issues. These feeding issues are all about the 9mm magazine not being properly positioned in the lower receiver. That’s kind of the “secret sauce.” If you want a gun to feed well, all you have to do is look at the Beretta 92.

The Beretta 92 was not the best handgun in world…but it was the best feeding handgun in the world. In that design, there is everything you need to know about how to design a carbine…

Ultimately, you want the bullet to be positioned to where it can go straight into the chamber…and very few got that right. There’s a couple of people who did. JP did a great job on their lower because they saw what the issues were. So, we changed how we positioned the magazine in the mag well, and literally out of all of the thousands of units we’ve sold, there’s been no negative feedback about it not feeding.

Q: I run ball as I don’t ever intend to use my 9mm PPC build as a home defense gun, but I’ve heard that hollow points can also be an issue. Is that accurate?

Paul Noonan, FM Products: There are challenges, no matter what the platform is, to shooting hollow point rounds. I know that can be a deal breaker for a lot of guys who want a “home defense weapon” and they want to shoot and train with hollow points. The reality is with so many hollow points on the market, it’s not always possible for every gun that’s out there to handle them…For us with the FM9, we found that polymer-tipped hollow points solved the issue…but there are just some disadvantages for a blowback.

Q: Earlier you mentioned bent sheet metal being involved with last round hold open…and how that was a bad thing. Can you walk us through that?

Paul Noonan, FM Products: Sure, the last thing that I see as flaws in many 9mms is the bent sheet metal last round bolt hold-open. Bottom line, It doesn’t work. It’s known to not work. Most people just pull it out of their gun.

For the layperson…on a standard AR-15, Eugene Stoner did a good job designing it. There’s a spring that keeps the bolt stop down when the magazine follower is not lifting up on the bolt stop. That spring’s only job is to keep it down so that the bolt can travel over the top.

Pushing Up and Down

For a blowback 9mm, many companies have cobbled together a design…You’ll see that there’s one spring keeping the bolt stop in place, and then that bolt stop is attached to a piece of bent sheet metal, and there’s a spring that’s there to push up on that piece of sheet metal. So, in a nutshell…you have one spring pushing the bolt stop up, and one pushing the bolt stop down. It makes no sense.

Q: You mentioned burst fire issues…can we talk about that briefly?

Paul Noonan, FM Products: We see people doing what we call a short stroke. They want to limit the travel of the carrier to just behind the bolt stop, thinking it will reduce the wear on the bolt stop…the trade off is what it does to the gun is really, really bad. You’ll see buffers that are really long to limit the travel of the carrier. The problem is if you use a really long buffer to limit the travel of the carrier, you’ll end up getting burst fire.

Q: So, you’ve avoided issues you feel the 9mm PPC has historically suffered from. What else should people know about FM Products?

Paul Noonan, FM Products: We make everything in-house except for the springs and the furniture. We have two manufacturing facilities. We’ve partnered with Primary Weapons Systems here in Boise and utilize their capacity to make our product and license our product to them.

PWS and I are very good partners. We’ve worked on projects together and we have a very good relationship. Bottom line…we spare no expense, we use only the best materials and we have great attention to detail.

For example, look at our bolt carriers. We’ve sold tens upon tens of thousands, and we average half of one tenth of one percent sent back with a question or an issue. Issues happen…there is no perfect product or perfect company. But, everything we do, we give our absolute best.

As an example, our extractors are S7. We don’t have to make them out of that, but we spent the money to make them out of S7 and we have literally never had an extractor break…not one time…We do long duration QPQ, which has about five times the penetration of standard QPQ…just little things like that. Our carrier key is stainless steel…We give them an M67 retaining pin. That’s stainless steel. The weight, the slug in the back…I don’t have to make it stainless steel, but I do because for a little bit more money you get all this great corrosion resistance on a blowback, which is a very dirty mechanism. So, anything you can do to mitigate that is a smart thing.

But, I’d say go take a look at the reviews of our bolt carriers over at Brownells. Everybody is using them. It’s the number one seller at Brownells. We can’t keep them in stock. We literally cannot make them fast enough.

Q: How do you explain that popularity?

Paul Noonan, FM Products: We are just better at machining, and because of that we can have a more feature rich higher quality product at a better price…Our job is to make a product that is better, for less money than the “Gucci” stuff. We care about our product and we care about our customers. Our philosophy was if we did both, the consumer would figure it out…and we were right.

“You Earn Your Reputation”

We’ve been in business 18 months, and we’re doing a million dollars a month. It’s unheard of. And everything that has happened, it’s happened based solely on customer feedback. Our business grew because someone told their friend about it. You earn that. You earn your reputation in this industry. People spend money on marketing…we spend ours on our customers. If a customer has a problem…I take care of it. I fix it for them. If you get a frustrated customer and you turn that around, that is the most loyal customer you’ll ever have. I’ll be damned if I let another company treat their customers better than I do.

My thing is I want to serve blue collar people that support the 2nd Amendment. I do that by providing feature rich items at a great price that’s better than most stuff that is out there for twice the money.

###

hello I wanted to know if the tip of the barrel tri lug is an integral part off barrel or if it is possible to remove it to change it I want to put the tri lug angstadt model ? https://angstadtarms.com/product/3-lug-muzzle-brake/ ?

ok I got my answer, it is an integral part of the barrel