ARBuildJunkie recently sat down with Pat Murphy of Faxon Firearms to discuss the company, its AR barrels, advice for builders, and what he’d recommend for a first time build.

Q: Pat, first off, can you tell us briefly about Faxon Firearms?

A: Faxon started in 1978 in Cincinnati, Ohio. The company is owned by two brothers, Bob and Barry Faxon. Bob and Barry have been running Faxon Machining since Bob was about 20 years old. That said, I think Bob has been on a machine floor since he was about 12 years old. So Bob and Barry, they’ve been running the business for a long time, involved in the oil and gas industry, the automotive industry, the medical industry, and in aerospace. They have done work for NASA. They’ve really just run the gamut of machining work.

As it so happens, they are also lifelong firearms collectors and enthusiasts. In 2012, Faxon Firearms was born out of a desire to bring their engineering and manufacturing expertise to the firearms industry.

Q: Faxon’s barrels feature button rifling. Can you talk about what that means both from a manufacturing process, and also what it means for the shooter?

A: As background, there are basically three forms of rifling. Cut, button, and hammer forged. We do buttoning. This involves pulling a little piece of steel through a very small hole to create the rifling in the barrel.

At Faxon, we do all of this rifling and machining in-house. We make and grind all of our barrel extensions. Doing these things in-house allows us to control every step of the manufacturing process. It also allows us to keep our prices down. We don’t have any inflated costs from subcontracting services out.

As for button versus cold hammer forged…this is something that people get into a lot. Neither one I would say is superior. Each has benefits and each has downsides.

Someone who does button rifling well will create a great barrel, just like someone who does hammer forged barrels well will do great barrels. The difference is there are only a couple hammer forgers in the country.

As for Faxon’s button rifling, we believe it results in more accurate barrels. Hammer forging can induce a little bit more stress into the barrel because you are hammering the material around the mandrel. It’s actually expanding while its just getting hammered by thousands and thousands of PSI of force. For us, button allows us to make very accurate barrels but it is also a very efficient process that allows us to keep costs down as well.

Advice for Builders

Q: Being a manufacturer, you have a unique perspective on building an AR-15. What advice would you share with someone who has decided to build a rifle? What should they be looking for in terms of parts selection?

A: The first big thing I would tell any newer builder is to know the purpose. What is it going to be used for? Let’s say you are building for recreational shooting, or perhaps you are going to take some rifle classes. That purpose is going to lead you to pick a specific barrel. Now, let’s say you want to dive into high precision shooting at 1,000 yards. If that is your purpose, then that pursuit of long-range accuracy is going to lead you down the path to an altogether different set of specs.

Start with 5.56 or .223 Wylde

Another thing I recommend for first time builders is to stick with 5.56 or .223 Wylde. The reason why is parts, for the most part, are interchangeable and should fit well together. That spec has been around a long time, so part interchangeability is very wide…as opposed to say AR-10s.

Having the Proper Tools to Build an AR

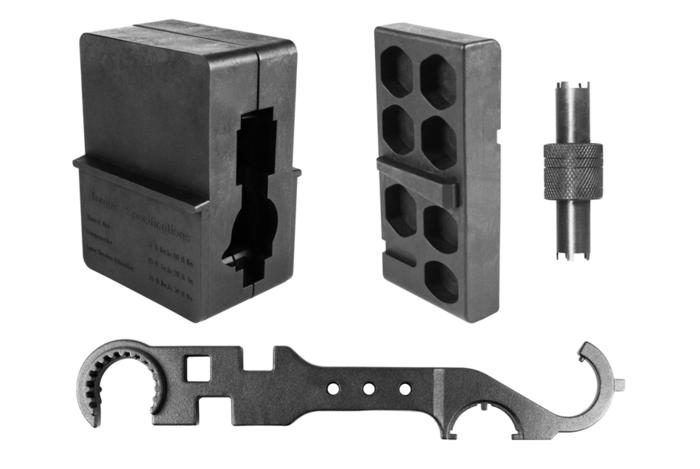

Aim Sports AR Armorer’s Kit – MSRP – $49.99

Another big thing for new builders is to spend money on quality tools up front. Having the right tools to build a rifle will save you a lot of time and headaches. Stuff like punches, roll pin starter punches, a reaction rod for installing your barrel, headspace gauges. There’s a whole list of tools that we recommend getting. And typically it’s a one-time purchase.

It allows you build it the right way rather than using a tool in a way it wasn’t meant to be used, For example, using the wrong wrench and not torquing your barrel down enough. Having the right tools there and ready to go is just a huge help when you’re getting started.

Buying Matching AR Parts

Another piece of advice has to do with matching certain parts together. We recommend if you are going to buy a barrel…if the company you are buying the barrel from produces bolts, then we say buy both from the same company.

You do this because you can then know from a certain level of certainty that those parts are going to work together.

Here at Faxon, we check 100% of our bolts and barrels to make sure they are in the correct headspace ranges. On top of that, if you buy them from our website you can have us double check that specific bolt with that specific barrel and even laser engrave the matching number between the two of them so you know that they go together.

Faxon Firearms 5.56 LIGHTWEIGHT 9310 Bolt Carrier Group Complete – Nitride – MSRP – $249.00

The Importance of Proper Headspacing on an AR-15

Speaking of headspace…this should be a concern for the new builder. Proper headspace is absolutely critical. Having bad headspace can mean as little as the gun not functioning properly, to as bad as having a catastrophic malfunction and actually blowing up.

When you have something like a 5.56 round with 50,000+ PSI shooting off near your face, you do not want an explosion that is not contained properly.

Q: With so many barrels on the market, what should buyers be looking for in a barrel for an AR? What makes a good AR barrel?

A: Again, I want to repeat that you have to lay out what you want that barrel to be used for. But beyond that, the tough part is a lot of the things that make a good barrel are not easily identifiable.

For example, you’re not going to be able to tell concentricity. So for us, we make sure we guarantee concentricity. We measure it with precision air gauges within 2/10 of a 1000th of an inch. That is the level of deviation you can have in the center line of the bore. This is an absolutely huge thing because it dictates where the bullet goes.

Inspecting the Barrel and the Chamber for Defects

One thing you can look for is the quality of the rifling, You need to make sure there are no burrs or buildup in there. Everything should be mirror smooth.

A high-quality chamber is also vital. Like the rifling, you don’t want any roughness in there because it will impact your function. If there is too much grit or buildup, the case is not going to want to extract.

Also, looking at the crown of the barrel, which is the muzzle end – make sure you do it with the barrel not attached to the gun – make sure the crown is smooth. This ensures the bullet flies straight once it leaves the barrel.

Stress Relieving the Barrel and Lightweight AR Barrels

Finally, another thing you are not going to see but is critically important is stress relieving. Faxon does all of this in-house, which allows us to make sure we can make the highest quality barrels. This is especially important when it comes to our lightweight barrel offerings.

Lightweight barrels do heat up quicker. The key to their performance is how well they are stress relieved. If done properly, you’re not going to see many negative effects with them heating up like you make have had in the past with like the old Colt SP-1 stuff. There’s a phrase people would use. They would say “the gun would start walking.” This meant groups would start becoming erratic.

With modern stress relieving processes, that has all but been eliminated. Now, you will see with lightweight barrels that groups open up, but typically you’re not going to have erratic groups.

Q: So you’ve briefly touched on your lightweight pencil barrels. Can you explain a bit about the different barrels that Faxon offers?

A: Sure. We have a few flagship profiles. The pencil is one of our most popular. We also have our Gunner profile, which is a hybrid lightweight. This would typically be used if you want to go a little bit lighter, but weight is not the biggest factor in your decision.

On the Gunner profile, the diameter behind the gas block, that is actually a SOCOM profile diameter, then on the front of the gas block is the pencil profile.

What that does is add a bit more material back where you really want it, around the chamber and the first few inches of rifling where you get the most heat and erosion. What that means for the shooter is it adds a bit more weight but adds it back towards the shooter so it helps balance out that gun more.

Personally, we are huge fans of the Gunner. We see a lot of success with it because it gives you some of the weight saving, but you are getting the benefits of having a slightly heavier barrel.

Moving on, then we have the tried and true SOCOM profile available in many lengths. These are your standard medium to heavy use profile. They hold up to full-auto very well. They are a little bit heavier, but still not too bad.

Finally, we have our more accuracy-oriented profiles. We have both a heavy fluted and the flame fluted. These barrels are stainless steel, 5R button rifled, with Nickel Teflon extensions. We’ve found that little things like that are features that lend themselves to better accuracy.

A Basic Build

Q: Final question. Imagine you’re a putting together a first time basic build. What direction would you go?

A: If I were going to create a basic, first-time build for you, I think I’d recommend you go with our 16” gunner profile barrel either in 5.56 or in 223 Wylde.

I would advise you to go with a quality forged receiver set, or if you want to go billet because you like the look of somebody’s, go for that.

I’d then say go with our 15” aluminum hand guard. Those retail at $165 dollars.

Then, I’d go with our 3 port gunner muzzle break, it allows install without use of a crush washer which can be a huge headache if you don’t have the right tools. That said, as I recommended before, try to have the right tools. It makes life so much easier.

Moving on, I would choose a standard lower parts kit. As far as a trigger, I would tell you to choose something like an ALG or a Geissele.

and I think I’d finish it off with any of the Magpul stocks. I think if you built that, you’d have a great gun that could do a lot of things and do them very well.

Special thanks again to Pat Murphy, National Account Manager at Faxon Firearms for taking the time to sit down with us. For more information about Faxon, hit us in the comments, or visit Faxon’s website.

2 - 2Shares

so Legit Arms shows you everything related to this world to help you decide on the one that best suits your

taste and needs. Please feel free to visit our website

https://www.legitarmsdealer.com/

Thank you for sharing and nice articles you have here <a href=”https://fluffyshihtzupuppies.com/”>Buy Fluffy Shih Tzu Puppies Online</a> moreover the admin of this site has really worked hard for all this once more thanks for sharing your articles.

Thanks for this fantastic post. It was so great to see so many amazing ideas that can be implemented easily.