Dave Wilson of D. Wilson Manufacturing is a true master of his craft, whether it be pin & welding, upper and lower assembly, shortening a barrel, custom modifications, and more. We spoke with Dave Wilson last year, and you can read that article here. In this article, we sit down with Wilson to discuss common mistakes to avoid when building an AR-15, when to seek help, his perspective on industry-wide quality control issues, his personal AR-based projects, and more.

Q: I imagine you field a lot of questions from AR builders. At what point should someone contact you if they feel like they are over their head with building an AR-15?

Dave Wilson, D. Wilson Manufacturing – I am a big proponent of the internet, and I love to be able to find an answer to whatever query I have in a matter of moments. While this is great in many ways, for the novice building an AR-15 upper or lower, it can undoubtedly be challenging knowing where exactly to turn. There is so much information, and it can be overwhelming. There are also so many different options in terms of gas system length, barrel, buffer weight, buffer springs, and more.

For someone who has trouble digesting all of that or does not have the tools or equipment to put together an AR correctly, they might find it worthwhile to contact us to ask some technical questions or get some hands-on support.

Q: What are common mistakes you see, and is there a point where someone should recognize it is time to back off and seek help?

Dave Wilson, D. Wilson Manufacturing – The biggest, most common mistake that we regularly have to fix is stripped threads on the end of the barrel. If you’re in over your head, it is something that is very possible to do. Perhaps you pushed something past where you should have, or if something was slightly out of spec with a part you purchased. While it seems straightforward, it’s certainly an area of assembly where you want to be careful.

The other thing I see a lot of is stripped screws. Wherever things thread together, you can pretty easily get something cross-threaded. Once that happens, it can be pretty easy to overthink things and just try to drive it home. This is another area where it pays to go a bit slow and make sure that you’re not in a rush, or trying to force something. Those are the two biggest things that I see, and areas to not rush through as you’re building your own AR at home. Don’t force things. It can easily lead to a bad outcome.

As some one new to building, there are other mistakes I see that you can stumble into. For example, while it’s second nature to me, there are many things that go into picking a barrel and a handguard.

There are lots of little details that you have to get right – gas system length, the overall length of the barrel, gas block journal size, and how that correlates to the gas tube and may affect whether or not the gas block is in front of or inside the rail. Overlooking those details or not realizing how those details may affect one another is a common technical mistake when newer builders start building an AR-15 upper.

Q: If someone is new to owning or perhaps building an AR-15, what is the best advice you can give them on the process?

Dave Wilson, D. Wilson Manufacturing – That’s a good question, as I get asked that from friends and family. If it’s someone’s very first AR, I will try to encourage them to perhaps start with buying one off-the-shelf versus hopping straight into building. Then take that AR that’s already assembled and ready-to-go to the range and shoot it.

Do so with the intention of determining what you like and don’t like about the firearm. In my mind, there is no sense in going out and spending a lot of money unnecessarily on building an AR from parts only to end up not being happy with it.

Rather, I’d take that off-the-shelf gun, determine what you’d like to change, and then do that. There’s a lot you can do, including upgrading the sights, the handguard, the trigger, small parts and accessories, add an optic. That said, my advice to your readers is to only upgrade if you genuinely need it. Realistically determine what you are going to do with your AR and go from there.

Q: I’d imagine people send you parts of varying quality. What do you look for as you’re purchasing parts for your AR builds?

Dave Wilson, D. Wilson Manufacturing – If I’m building an AR-15, I look for parts where I have some sort of personal connection with the owner. Outside of that, I’d be looking to a company that has a name and face behind it and who stands behind their products. For myself, I know that if something goes wrong, the company will work towards making it right, either sending a replacement or talk me through some technical aspect that I may not fully understand.

I understand that people may be price-conscious when purchasing parts, and I am to some degree, but there is something to be said for aftermarket support that companies can provide. I’ve been doing this forever, and I know that sometimes, things simply get broken when building an AR-15. It’s something to consider.

I actually broke something on one of my LMT guns, and it was my own stupid fault, but I called LMT, and they were happy to send me a replacement. I think that goes a long way, and I think it’s important to research companies and look for those that will stand by you.

As you’re building an AR-15, If you don’t know what to look for in a company, as a consumer, I think you should try to track down online reviews. You can do something as simple as search a company’s name followed by the word “problems” or “issues.” You can uncover other builder’s experiences, whether good or bad. It’s essential to do this sort of basic research when you don’t have friends who are shooters or builders, and you don’t have access to good, first-hand information on what’s good and bad.

Q: You’re in a unique position, as parts are constantly being sent to you. What is your impression of parts quality and overall quality control over the past 12-18 months?

Dave Wilson, D. Wilson Manufacturing – (Laughs) So, I’ve had some interesting things occur over just the past few weeks. I can’t say I’ve ever had to cut off as many muzzle devices as I’ve had to in the past three weeks. Some companies have really dropped the ball on quality control over the past six months. You need to be careful if you’re building an AR-15, even with companies who usually have had good quality. Chad Albrecht at School of the American Rifle mentioned this months ago, and he was correct.

With the huge demand, different companies are going to respond in different ways to that. Are they going to ramp up their production to meet customer demand, and sacrifice quality? That’s one option. Are you going to hold true to your quality and NOT keep up with the demand? It’s not up to me what companies do, but I will say I have seen parts over the last few months that have not worked for one reason or another. In most cases, we’ve been able to exchange them, but in some cases, the company will claim they have never, ever created a bad part, which is a bit concerning. To answer your question directly – yes, I have seen a drop-off in parts quality in the last several months.

Q: Knowing that quality control is down, what advice do you have for people other than ‘buyer beware” when buying parts to build an AR-15?

Dave Wilson, D. Wilson Manufacturing – My advice is two-fold. As I alluded to earlier, one is to try to purchase parts from a well-known company that has been around for a while so that if you do have an issue, hopefully, you can work with them and get a replacement part.

Secondly, as a proactive measure, you need to make sure that you, as a builder, are being extra stringent in checking things like suppressor alignment, as an example. Normally, this is something that your readers might take for granted when they are buying from a well-known company. However, I have seen quite a few suppressors, mounting devices/adapters have tolerance issues where each part might be on the fringe of tolerance, but when you stack them together, it throws the tolerance way off.

Q: I’ve noticed that when builders seek assistance online, there is often a tendency for those “helping” to flippantly tell that person to “just send it.” At what point do you not “send it” and seek help?

Dave Wilson, D. Wilson Manufacturing – One of the bad things about the internet is that you have a lot of people with a lot of opinions, and not all of them are offering sound advice. If you look at the risk versus reward of “just sending it” to me, I take my health and personal safety somewhat seriously. I don’t think I would ever “just send it” with a firearm. You have tens of thousands of pounds of pressure of a cartridge igniting inches from your face. That can be catastrophic given the right chain of events.

If you ever have doubts as you are building your AR-15, it is important that you seek out the advice of a professional. It’s crucial to vet who that professional is. The guy at the local gun store who only has experience with birdshot and bolt actions may not be the best person to ask (laughs).

Heck, if you see someone at the range with an AR-15, you could ask them, provided you take their advice with a grain of salt. I’d also recommend that you reach out to the manufacturer of the part you are having an issue with and describe the issue the best you can.

Now, the feedback you get might range from “maybe we should take a look at that,” to “the suppressor alignment doesn’t look great, but we’re going to have to warranty it either way, so just send it.” I don’t know how reassuring it would be to hear the latter option from a company, but again, it’s not my company to run.

With any work my company has ever done, if someone ever has doubts, I’d absolutely want them to reach out to me. It might be something we missed in our quality control measures, or it could be something they did after the rifle left our shop that could be cause for concern.

Q: Finally, you build a lot of guns, what are you making for yourself recently?

Dave Wilson, D. Wilson Manufacturing – My pet project is an LMT MWS I’ve been tinkering with lately. I love tinkering with guns. I wouldn’t be doing this if I didn’t. One thing a lot of people ask me about is when I am going to start offering barrel conversions for the LMT MWS. A few weeks ago, I was at the shop, had a beer, and got to thinking I should put a Proof Research barrel in my personal MWS and see how it works out.

Lately, I’ve been developing more of an interest in long-range precision shooting, and I would say one major downside for me of an AR-10 is just how heavy the darn things are. If I go to a match or I am out in the woods, it’s not something I want to lug around all day. So, I was trying to figure out ways I could get the AR-10 lighter, and I love the quick-change barrel system of the MWS, so I sat down and figured out how I could shave some weight out of it.

Right now, the rifle is chambered in 6.5 Creedmoor with a 22″ Proof Research barrel in it. The barrel is 6″ longer than the factory barrel and 6 oz. lighter. I came up with some other ways to shave another half-pound off the gun, so now I have a gun that’s 10 percent lighter, a bit more pleasant to lug around, and I am making hits out to 1,000 yards. I’m pretty happy with it, and my thought is that if I am interested in it, there have to be others that would be as well. I want to keep testing to see if it’s worthwhile and durable, but so far, I’m enjoying the conversion.

Q: Anything else you’d like to add?

I have been very fortunate in the growth of the business over the past year, and as things have stabilized a bit, it gives me the opportunity to work on some cool backburner projects like my MWS conversion. I like to push the norm and explore new things.

My advice to anyone in the industry is to take some time and pursue your interests. Chances are, if you are interested in it and talking about it, you’ll find others who are interested in the same thing. That can open up a whole new subset of the market if there is enough interest. You’ll never know if you don’t try new things.

It’s never a bad thing to stretch and get a bit outside your comfort zone. That can be someone building an AR-15, or someone like me, just wanting something a bit different. Follow your interests and don’t be afraid to try new things.

###

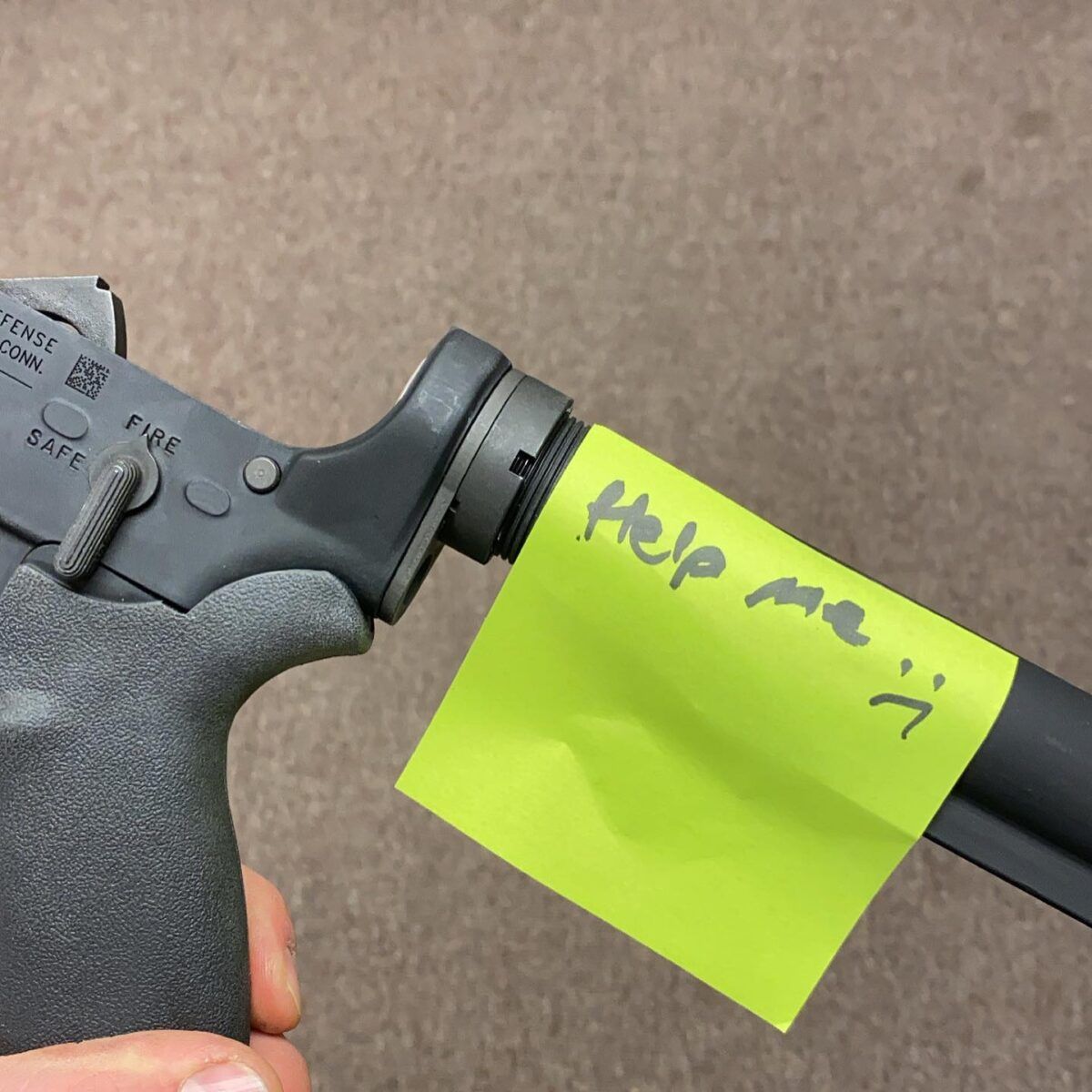

I need help I just bought ar15 is there suppose to be a gap

Need help first at r they suppose to have a gap in front barrel meat