We recently sat down with Alex Bohl from Trajectory Arms to discuss how you can avoid common and costly mistakes when building an AR-15. As a professional builder, Alex knows his way around the AR-15, and has a unique perspective on the tools and parts needed to successfully build a hard-use AR.

Q: How is being a professional builder different from being a hobbyist?

Alex Bohl, Trajectory Arms – Last year, we moved to a commercial location, as prior, we were doing work out of a shop in my basement. Moving allowed us to buy machinery, hire help, and better serve our customers. I think a hobbyist can maintain the same mentality as a professional builder and actively seek out new information and better ways of doing things.

One of the most significant advantages is that we already have all of the tools, gauges, and equipment set up and ready to go. We also have access to a wide variety of parts so that if someone has something like a loose gas block fitment, we can search through our bin and find a gas block that has a tighter fitment than the one that we were originally stuck with as a hobby builder might be. Too often, a newer builder will get all of his parts together and start building an AR-15, only to allow the excitement and anticipation of having that completed firearm cloud what would typically be concerns.

Q: Are there tools that we should be collecting as builders for building an AR-15?

Alex Bohl, Trajectory Arms – Certainly, there are essential assembly tools, and fixtures that will go a long way in helping to build an AR the right way. There tend to be a lot of issues that present themselves when someone tries to shoehorn something together without having the proper tools. I see issues often when builders try to take a shortcut. By trying to save money, they can actually cost themselves.They might do something like have their buddy hold the gun while they try to torque down the barrel nut. Having tools available and ready to go makes a big difference.

When building an AR-15, I know there is a lot of noise over things like gauging. While I don’t necessarily think someone needs a big pile of gauges and specialty tools, it is at least advantageous to have access to those because they can help you identify a problem before you start the assembly.

Q: What problems are common that you see when you don’t use the proper tools?

Alex Bohl, Trajectory Arms – If it’s not put together correctly, you can certainly see issues. Use something like under-torquing a castle nut, for example. If you do that, you can risk the firearm coming apart while it is being used. If they didn’t have a good fixture and torque wrench to reach the appropriate torque value for it, it will not hold together as it is designed to. Alternatively, if they are applying too much torque on it because they don’t have the ability to measure, they can strip out threads or damage components.

As far as what tools to buy or how much to spend, I think that depends. The quality of the tools you purchase should match your intended use. Being realistic, If you are building one gun, you can probably get away with some cheap punches, wrenches, etc., as long as they are doing their job correctly. A torque wrench, for example, should be accurate. What I mean by that is that the torque that you apply to the wrench should match what the wrench is telling you.

If you plan on doing something more in-depth, perhaps you are a department armorer, and you are working on things professionally, it’s going to be worthwhile for you to purchase better tools that will last longer and won’t wear out as quickly.

Q: I’d heard that you were working on a tool for receiver extensions? What’s the story with that?

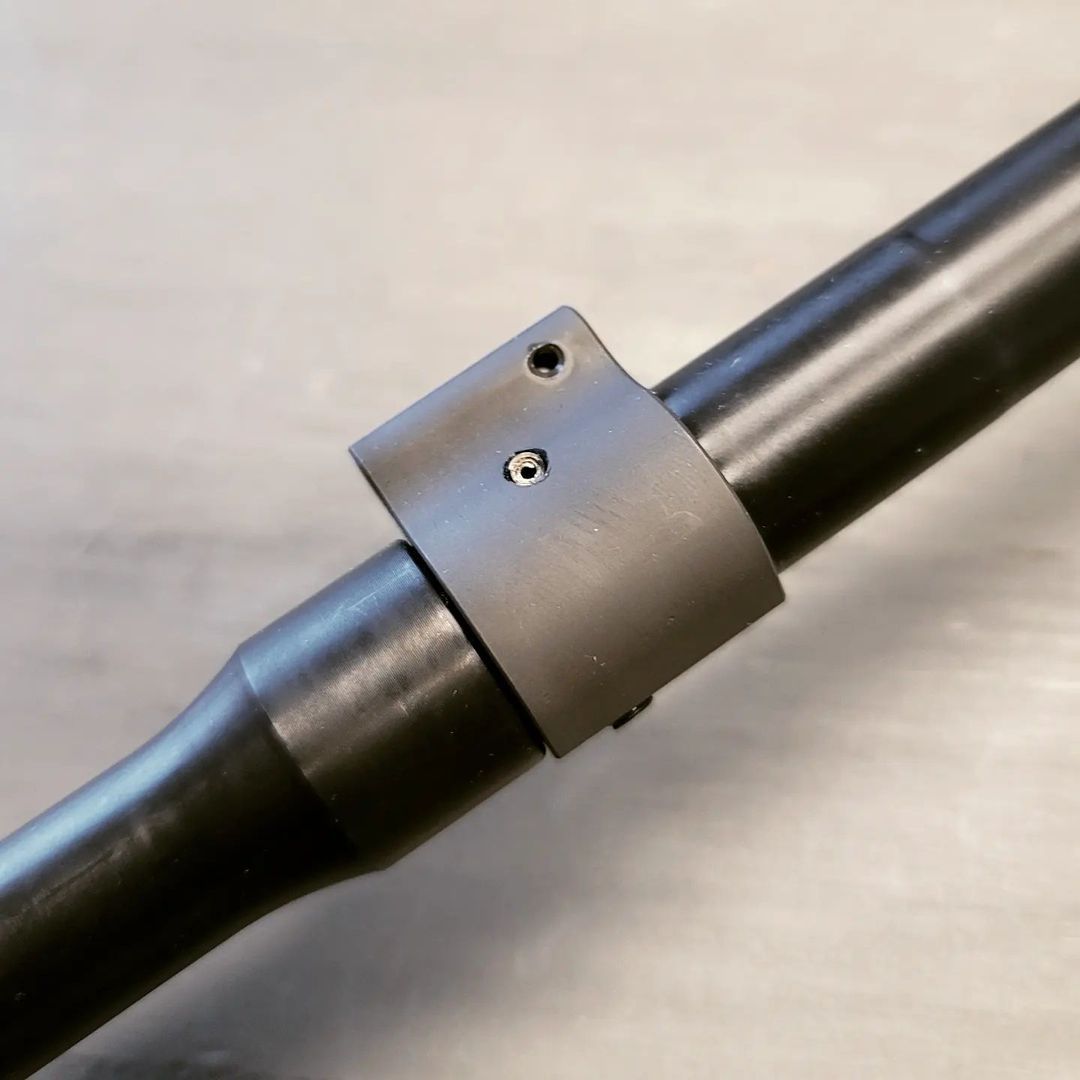

Alex Bohl, Trajectory Arms – It’s actually a development from a friend of ours, Paul Wallace. It’s his design, and he’d been talking about making it for a long time, but we had the ability to help him bring that tool to market. Between his design and our testing and feedback, we think it will be an excellent tool that works with the Geissele Reaction Block. It is designed to hold a receiver in-line with the receiver extension while you are torquing the castle nut.

This helps in a few ways when building an AR-15. When you are installing the castle nut, it keeps everything aligned. There is usually a bit of play on the index channel of a receiver extension, and this keeps everything straight. It can also be used for removing castle nuts. The benefit is that it keeps you from over-rotating the receiver extension and potentially damaging the threads.

Q: Gas systems are something that a lot of builders send us questions about. Can you share some of your advice on do’s, don’ts?

Alex Bohl, Trajectory Arms – The single biggest thing that people can do is ensure that the system seals efficiently. Its job is to deliver gas from the bore of the barrel to the bolt carrier, allowing it to unlock, and you need enough gas for it to do its job, but not so much that you are unlocking too early.

The biggest issues we see when building an AR-15 tend to come from loose-fitting parts, and sometimes that is attributable to tolerance stacking from different manufacturers. That said, factory guns are not immune to issues. We have also seen barrels and gas blocks pinned from the factory that are loose and leaky. My guidance on this is to treat it similarly to water pipes. Ensure you are minimizing leaks and pairing your gas block up with a barrel with the proper gas port sizing for the application.

Before you try to install any parts, as a builder, you need to test everything to see if it has a good, snug fit. This might take some time, but it’s worth it. Common sense comes into play here, and you should fight the urge to push past an issue or concern because you want to get your build finished.

For example, as you’re building an AR-15, a gas block that you can flick with your finger and spin around the barrel is probably not going to give you a good enough gas seal against the barrel. Another good pointer is always to dimple the barrel, preventing the block from moving. Also, use knurled set screws and Loctite. You’d be surprised how many builders don’t do these simple things.

Above all, as you’re building your AR, take your time, do your research on what you’re doing. Make sure there are no issues with the parts you’ve purchased. There are plenty of good resources out there, and there’s just no reason to rush the process or assume that the quick and easy way is “good enough.” In my experience, I’ve seen that over and over, and it leads to bad things, and guns that do not function as efficiently as they should, if they function at all.

Q: I’ve seen you discuss pistol length gas systems online recently. Can you discuss why choosing that length is not ideal?

Alex Bohl, Trajectory Arms – A pistol-length gas system is obviously great for 300 Blackout, but it does not work out well with 5.56, and that has to do with timing the unlock. Your chamber has not had enough time to decompress before you start the unlock process, and so your cycle tends to be pretty violent as you’re trying to extract a round that isn’t quite ready to be extracted yet. The gasses at that point are really hot as well, and they tend to erode parts badly. We’ve seen gas tubes that are cut right at the inlet port, just from the cutting effect of those gasses.

Q: Understanding that guns wear over time, why should someone consider some of the inspection services that you offer? At what point do you think someone should have an AR inspected?

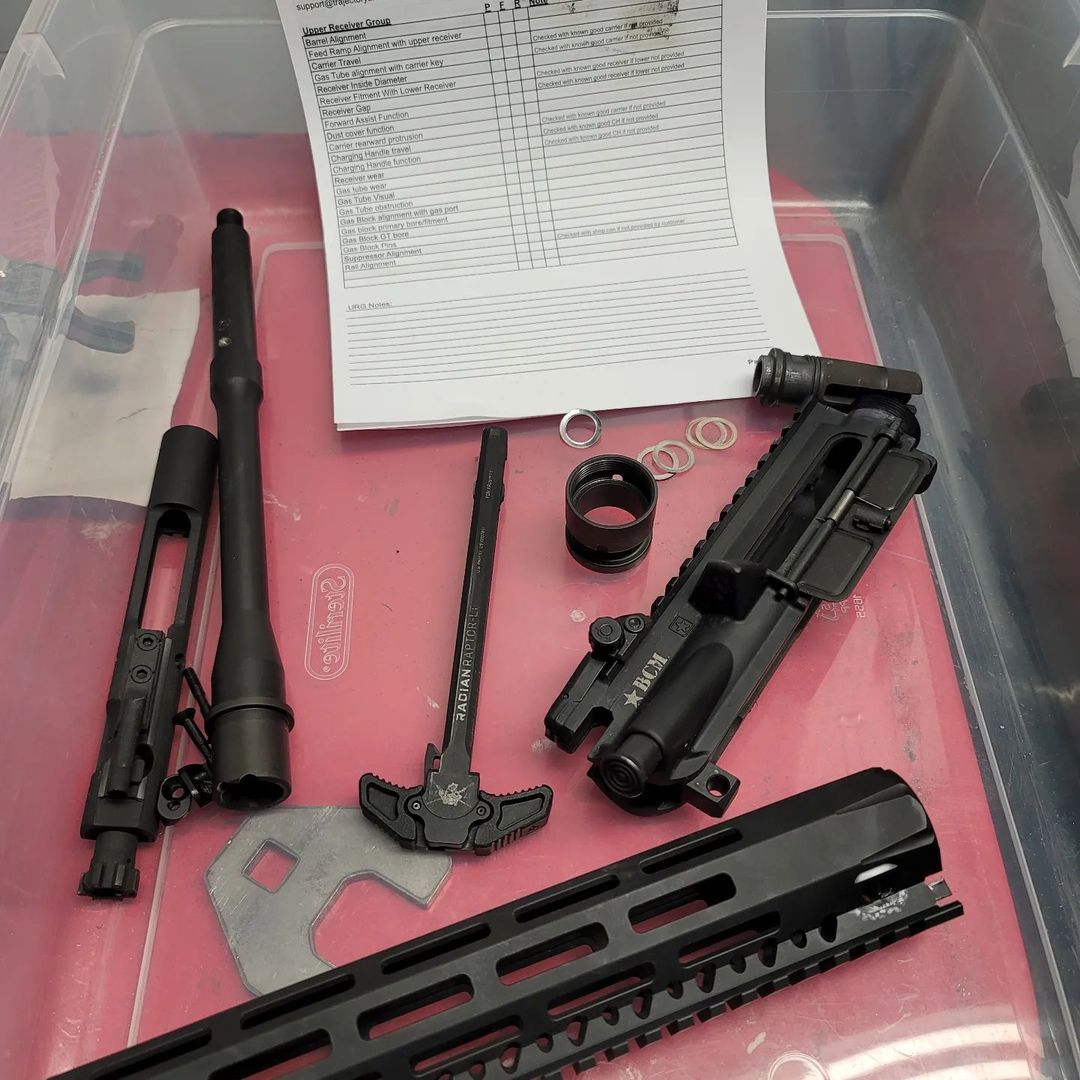

Alex Bohl, Trajectory Arms – Our inspection services are designed to give you access to the tools and gauges that we have, and give you the quality control you’d expect from a factory rifle while allowing you to customize it however you’d like. The way we look at the rifle, we don’t just want it to run, rather we want it to run efficiently.

A good analogy would be a truck with a bad cylinder will still go down the road, but it is not exactly running efficiently. It is not going to tow very well, and your likelihood of breaking things internally by running it in that condition for too long is high.

We try to identify problems before they happen and make the system work smoothly so that you can get a longer lifespan out of the gun without compromising its ability to do its job effectively.

Q: In your line of work, you have a unique view of quality control on parts. What are you seeing out there regarding the quality of parts?

Alex Bohl, Trajectory Arms – From my perspective, the ability of the person building the gun to identify out-of-spec parts when building an AR-15 is becoming more and more crucial. I’ve seen bad eggs from pretty much every company. The question then becomes who to buy from to lessen your chances of bad parts. If you buy parts from a company whose primary mission is to build guns correctly rather than a profit-first mission, you will be in pretty good hands.

Companies like Forward Controls Design, Sionics, Sons of Liberty all have similar missions in that they genuinely care about the overall effectiveness of the final build. On top of that, if there is something wrong, they are fast to take care of the customer if the need arises. I can’t say that about the majority of the companies on the market these days. I say that because I have had to write emails to companies on behalf of customers to help them get things warrantied because the company was adamant that their part was fine, when in reality, it wasn’t.

Q: Too often, you can’t tell if a part is out of spec or if you’re doing something wrong. What do you do in that situation? Buy another part and compare the two? What’s the best approach?

Alex Bohl, Trajectory Arms – Unfortunately, that is the way it is sometimes when building an AR-15, and that’s one of the benefits of sending your build to an experienced armorer. Often, they can discern the small details that can make or break a part. It’s difficult right now because there are hundreds of manufacturers making thousands of different parts, and none of them are really talking to each other.

From my perspective, the quality of parts continues to deteriorate, making it a lot harder to build a rifle out of parts without running into fitment issues. Look for parts from quality companies and make sure you’re buying from reputable companies that value good customer service. Otherwise, you can find yourself stuck with a defective part and no one to turn to.

Q: So, if I have a collection of parts, your company will build the rifle if asked to do so?

Alex Bohl, Trajectory Arms – We do complete builds, and we can do that from parts that we provide or from parts that you provide. That process is essentially the same, but we can save you some money when we have some input on the parts that you send.

What we do is close to what you might call a “gunsmith fit AR.” In addition to making sure everything fits together, we are also trying to make things better as we go by fitting parts together, test firing to stress the gun so that when you take it out in the field with the appropriate buffer system, you are not going to run into any issues.

When we do an upper receiver inspection, we proof test it. Then we also send along a buffer and spring recommendation when you return it. You’ll see everything that we checked, and everything that was modified or repaired. You’ll also see test fire results, along with the buffer and spring recommendation.

Q: If you have a build that isn’t working, at what point do you consider sending it to someone for a closer look?

Alex Bohl, Trajectory Arms – In a perfect world, there would be no tolerance stacking, or out-of-spec parts, and we’d all have the right set of skills and the tools necessary to have a successful build, but that just isn’t always the case. When that happens, a lot of frustration can ensue. Building an AR-15 should be fun, but when that finished product does not work or is unpredictable, that fun can turn into a ton of frustration.

Having a build that isn’t working can also be time-consuming and costly. Depending on your situation, you’re testing different ammo, magazines, driving back and forth to the range, all the while not getting to the bottom root cause of what is wrong with your new build. I think when you find yourself at that point, it might be worthwhile to seek help and perhaps contact us. You can box everything up, send it to us, and be confident that you are going to get the problem with your build solved. Regardless of whether you reach out to us or someone else, do some research on finding someone reputable and experienced.

Feeling lost and frustrated with a build is no fun. Ammo is expensive these days, so it really depends on how much ammo you want to throw at it trying to figure it out, versus sending it in and having us go through it. Test ammo is a part of our fee, and we can usually sort out a problem without experimenting and throwing a lot of parts at it.

In the end, you’re going to get back a gun that you can be confident in. What we’re trying to do is build something that can be depended on and used for defensive purposes. I think that’s what many builders hope for their own guns. If we’re not confident that what we do makes that possible, we’re not going to send it out.

The bottom line is help is out there. Building an AR-15 can be a challenge and especially so if you’re lacking the proper tools and/or the knowledge about parts and their compatibility. As with any project worthwhile, go slow, do your research, know what you’re trying to build and the reasons behind your decisions, invest in quality parts, buy from quality companies that have a good reputation, and know when to seek out assistance if you run into problems. Issues are more common than they once were, and there’s no shame in asking for help. The real problem is building something you might one day have to depend on, only for it to fail in a time of need.

###

I enjoyed this article very much. It is nice to see people who know how to build correct AR rifles becoming more common..

[…] Building an AR-15 – Avoiding Common and Costly Mistakes […]