Let the experts at AR Build Junkie guide you as you choose the best barrel for your next AR-15 build.

Your choice of barrel can impact your rifle’s performance, longevity, and accuracy, so it’s important to find the right one to suit your needs. Here are the factors to considering different AR-15 barrels:

Barrel Lengths

Barrel length varies depending on what the gun will be used for. Lengths can vary from as short as 4.5 inches to as long as 26 inches. 16 inch barrels are very commonly used, due to their handy mid-range length and the fact that rifle barrel lengths of 16” or greater do not require a Class III tax stamp from the BATF. Popular barrel lengths include 7.5”, 10.5”, 12.5”, 14.5”, 16”, 18”, 20”, 22” and 24” barrels

When choosing the right length for your needs, consider shooting distance. If you will be shooting at longer distances, choose a longer barrel for increased accuracy and maximum projectile acceleration / velocity.

Lighter, shorter barrels are useful for shorter distances and confined areas. They are generally easier to carry and maneuver, and even conceal if needed.

Gas System

Today, barrels are often classified by gas system and belong to one of the following four groups: carbine, midlength, pistol, and rifle. There are also less common designations such as intermediate, and rifle+1, rifle+2, etc.

These terms refer to gas system length rather than barrel length. Barrel manufacturers will calibrate the gas port diameter to work well with a chosen gas system length, ensuring that the rifle will cycle properly.

While the manufacturer “tunes” these barrels to the best of their ability, there are variables such as ammo quality, bullet weight and the buffer system which can affect the cycling beyond just the gas system length and gas port diameter.

For example, most barrels are ported to cycle properly when used with a “carbine” buffer system.

If a “rifle” buffer system is used, the stiffer spring and heavier buffer weight may prevent the system from cycling properly. It is also common for barrel manufacturers to port these barrels so they will cycle even cheap underpowered ammo properly. This could result in an over gassed system when being used with high quality match grade ammunition.

Tuning an over gassed system could be as easy as using an adjustable gas block or playing with a heavier buffer weight. Tuning an under gassed system might require opening up the gas port a bit more (proper tooling and machining experience required) or adjusting the buffer system (lighter spring, lighter buffer, etc.)

Barrel Profile

Barrel profile affects both the barrel’s weight and shooting characteristics.

There are many different AR-15 barrel profiles, including: lightweight, government, heavy, pencil, and even brand-specific profiles such as Ballistic Advantage’s “Hanson Profile” and Faxon’s “GUNNER” profile.

In general, the heavier the barrel, the more durable it will be, and the more heat it can withstand from constant firing. However, a heavy barrel makes a rifle more difficult to maneuver. A lightweight barrel will be easier to maneuver but may react poorly to prolonged rapid fire usage.

The profile of your barrel can affect barrel flexion while shooting, known as “barrel whip”. When a bullet is propelled into a rapid spin, the stock may drop significantly, causing the muzzle to rise. This may affect shooting accuracy. While slim, light barrels (such as a “Pencil Profile” barrel) may not resist barrel whip as well as heavier, more rigid ones, this does not necessarily mean that you cannot achieve accuracy with a long, thin barrel, since other factors come into play.

Fluted Barrels

For shooters trying to minimize weight while maintaining accuracy, fluted Barrels are often a great option. The most obvious benefit being that flutes can reduce the weight of the barrel while maintaining rigidity. This helps mitigate barrel whip. Another, important benefit of fluted barrels is that the flutes aid in heat dispersion.

Long range precision shooters know that increasing the heat of the barrel can decrease its accuracy. Past a certain point, the hotter the barrel gets, the wider the groups it produces. Flutes, with their effect of increasing the surface area of the barrel aid in heat dispersion.

Barrel Twist Rate

Twist rate is essentially the number of rotations of a bullet compared to the inches it travels within the barrel after a weapon is fired. For example, the barrel of the very first AR-15 made by Armalite had a twist rate of 1:14, which means that the rifling took 14 inches to complete a full rotation. This rate was marginal at best, since bullets became unstable during testing in colder, high-pressure climates.

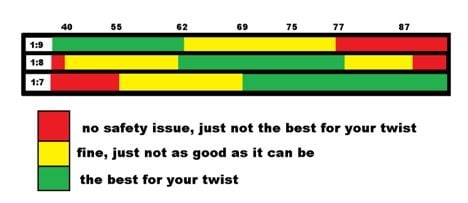

A faster rotation allows for more bullet stability. For example, a barrel with a 1:9 ratio means that a bullet will complete a full rotation after traveling only 9 inches. However, you must take into consideration the weight of the bullet you will use before choosing the right twist rate ratio. Generally, these are the recommended bullet weight-grain and twist rate combinations for .223/5.56:

| Bullet weight | Optimal twist rate |

| 40-62gr | 1:9 |

| 62-77gr | 1:8 |

| Over 69gr | 1:7 |

Keep in mind the chart above consists of recommendations for .223/5.56. Other calibers such as 6.8SPC II, 6.5 Grendel, etc. will have different optimal twist rates.

5R Rifling

Explanation of 5R rifling first requires us to define a couple terms:

Lands – the plateaus that interface with the projectile (bullet).

Grooves – the cuts into the bore. These are what stabilize the bullet by “twisting” or spinning it as it exits the barrel.

Conventional rifling is time tested and has been refined over the years and typically employs either 4 or 6 symmetrical lands and groves on the bullet. The lands and grooves are directly opposite of each other. There is nothing necessarily wrong with conventional rifling. Most barrels, including those in service with military or law enforcement feature this type of rifling.

5R Rifling on the other hand is an improved rifling method that changes the shape and relationship of the lands and grooves.

Firstly, it is an odd instead of even number of lands/groves meaning that they’re not directly opposite of each other.

Second, and this is a big one, the sides of the lands are slanted (less sharp) compared to the conventional rifling.

How does this help? When accuracy is paramount over long distances, bullet geometry is important. It has to cut through the air, so when there is less deformation of the bullet, it retains a higher ballistic efficiency. It also makes the bore of the barrel easier to clean. Less sharp edges mean less places for lead, copper or other superheated materials to get stuck.

Barrel Materials and Finishes

Here’s a summary of the types of materials available in AR-15 barrels, and the advantages and disadvantages of each:

Barrel Materials

- Stainless Steel. 416R Stainless steel is a common material used in precision AR-15 rifle barrels. Since it is malleable, it allows barrel makers to achieve finer precision and a much smoother finish during manufacturing. This precision often translates into better accuracy for the user. However, stainless steel barrels typically cost a bit more than a CMV barrel and have a slightly shorter life expectancy. Also, as the name implies, the higher chrome content of the alloy (about 13% by weight composition) means it is naturally corrosion resistant.

- Chrome Moly Vanadium Steel (CMV). This material is one of the most commonly used today. CMV is tough and hard and comes in 4140 and 4150 variations. 4150 is used by the US military and most barrel manufacturers.

- Chrome Lined. A chrome lined barrel has a coating of chrome added to the bore of the barrel to increase the barrel’s lifetime by preventing rust and corrosion. These barrels are also easier to clean than a standard Mag Phosphate unlined bore and have a longer life expectancy. However, the lining can make the barrel slightly less accurate than a non-chrome lined one, because of inconsistencies during application (microscopic divots, slight unevenness, etc). On the other hand, this slight inaccuracy normally occurs only at distances over 300 yards.

Barrel Finishes

- QPQ Nitride / Melonite. Nitride barrels are treated with a process sometimes referred to as meloniting, or QPQ Nitride or Salt Bath Nitride. It allows a barrel to be more resistant to corrosion and durable than chrome lined barrels, without sacrificing any accuracy. The general consensus is that a Nitrided (or Melonited) CMV barrel is superior to a Mag Phospate chrome lined barrel. It is also more cost effective.

- Parkerized / Mag Phosphate. Parkerizing, also known as bonderizing, phosphating, or maganese phosphating, is another type of coating designed to protect the metal of the barrel. Barrels are immersed in a solution of phosphoric acid and other additives to achieve a porous finish, which provides protection against abrasion and corrosion.

Chambering

An additional factor to consider is chambering, which largely depends on the type of ammo you will use. Since the AR-15 is so versatile, barrels actually come in at least 66 different calibers, from .177 to .50. A 5.56 is a common choice because it allows you to use both 5.56 and .223 ammo. However, you normally cannot shoot 5.56 ammo out of a .223 barrel because of the difference in pressure.

Below, you’ll find an overview of popular chamberings.

.223 Wylde

A .223 Wylde chamber can actually safely shoot both 5.56 and .223 ammo, due to the fact that it boasts chamber angling equal to a standard 5.56, while at the same time sporting a .2240

5.56 NATO

5.56 rounds are NATO approved for military use. One benefit of a 5.56 NATO chamber is its longer throat. In addition, these chambers have the advantage of being able to handle both 5.56 and .223 rounds. Check out the best selling Ballistic Advantage 16″ 5.56 Government Profile Midlength AR-15 Barrel, available from AR-15 Discounts. This incredible product from Ballistic Advantage’s Modern Series shoots both 5.56 NATO and .223 ammo and is manufactured from 4150V chrome moly vanadium steel.

.224 Valkyrie

This fairly new rifle cartridge is designed to achieve high speeds at long range. It can fire a 90-grain match grade bullet from an AR-15/AR10 rifle at about 2,700 feet per second. That means you can hit targets that are very far away (perhaps up to 1,300 yards) with the right optics. The Valkyrie also offers low recoil and less bullet drop. The aerodynamic bullets used for this cartridge are less likely to be affected by wind. Check out this article, where our interviewee

.300 Blackout

Also known as 300 BLK, This type of chambering was created by Advanced Armament Company to replace the MP5SD, a special ops 9mm machine gun. With a 300 BLK, you can shoot larger bullets similar in size to 7.62x39mm rounds used by an AK-47. It can also handle both subsonic and supersonic ammo.

7.62×39

Designed during World War II, these Russian-developed rounds are famously used for AK-47 rifles. Currently, 7.62×39 chambering is popular in the United States for home defense and hunting, specifically whitetail deer hunting and hog hunting.

6.5 Grendel

6.5 Grendel barrels, designed to take AR-15’s to a whole new level, can offer even

9mm

The 9mm is one of the standard pistol calibers used by law enforcement in most NATO countries. It can be ideal for close range and self-defense, and bullets are affordable and have very low recoil.