With the re-publication of Black Rifle II, now called America’s Rifle: M16/M4 late Cold War through Global War on Terror, by author Chris Bartocci of Small Arms Solutions, we wanted to reach out for some AR-15 buyer’s advice, what companies stand out to him in today’s competitive market, and more. Along the way we learned a bit more about what exactly ‘Mil-Spec’ means and why firearms from Lewis Machine and Tool (LMT) might deserve a closer look.

Q: Chris, congrats on the pending book, America’s Rifle: M16/M4 late Cold War through Global War on Terror. Can you give us the basics on what to expect from it?

Chris Bartocci, Small Arms Solutions – Certainly. Thanks for checking in. It’s my original book, Black Rifle II, under a new title. We just reorganized my background as there have been many changes since 2004. This is for the guy who is interested in the M16A2 moving forward. The book centers on military versions.

We don’t get into commercial. We then get into the re-birth of the AR-10. Then we start talking about Knight’s Armament and Reed Knight’s work on the SR-15. The book ends with Lewis Machine and Tool and the introduction of the LMT MRP system. When the book was written, Karl Lewis was getting ready to release his line of firearms because he had been an OEM manufacturer before that.

We will be working on a Black Rifle III soon, covering America’s rifle and enhancing the M4 platform from the War on Terror forward. In that book. We will start focusing more on the commercial side. This will be interesting because many enhancements have occurred from the commercial side of things. There have not really been many enhancements on the military side of things.

One of the most significant changes has been with the LMT MRP series and their sniper rifle for the UK, getting into the New Zealand and Estonia contracts. It’s a product that has been out since 2004, but no one really recognized it until the last ten years or so or less. We’re going to talk about the craze for external pistons, which started midway through the Global War on Terror. One of the things I have done recently is co-authored with Larry Vickers and James Ripley the second revision of AR-15 Volumes 1 and 2.

Q: If someone wanted your advice on what to look for in an AR, what would you tell them?

Chris Bartocci, Small Arms Solutions – There are two separate schools on this. One is for the hobbyist just going to the range, and another for the professional or someone very focused on self-defense.

For a guy going to the range who wants to build, you can engage in some mixing and matching. I’ve built custom rifles that were quite reliable. That said, you don’t have a TDP and can stack tolerances if you’re not careful. You may have to do some custom fitting here and there, and you may find that some parts might not fit together correctly. I don’t think that is a big deal for a rifle built for the range.

When it comes to law enforcement or military professional or somebody who is going to be using an AR in the real world, that is a whole separate ballgame. There are different requirements for those. They have specifications and go through testing, so you know they will work at -60 degrees just as they are at 160 degrees. They are going to work well, both suppressed and unsuppressed. You have parts that are manufactured by the same company, meaning that with the stack of tolerances, everything works together.

There’s a lot to consider. I am a big proponent of drilled and pinned gas blocks. That is done, so you have no possibility of the gas block moving. I like the idea of a proper Mil-Spec trigger where you don’t have a trigger that will go off accidentally. Some of the two-stage triggers I see are 3-pounds and under. There’s a reason military triggers are more in the area of 5.5 to 8.5 pounds or in that area. The barrels are another feature that I look at. Guys using these guns on a professional basis for self-defense as their primary role often will want a good chrome-lined hammer forged barrel rather than a stainless-steel match barrel…something that will not corrode on them.

In recent years, when discussing companies and quality control, I see a large cross-section of what is out on the market. My perspective is that many reputable companies are still doing a good job. If you pull a Sig, Colt, or LMT off the shelf, these will be high-quality defensive-grade firearms.

Other lower-end companies are primarily “assemblers.” They are buying parts from all over the industry and putting guns together. I think this is where you can potentially see issues arise depending on tolerance stacking issues.

These parts are not all plug-and-play simple. They are not all the same, unlike a Mil-Spec rifle that has a set of drawings for every single part. Every single part that is made is interchangeable and within those tolerances, and it’s going to work. It’s a degree of precision that you need that, I think, separates those guns.

Q: Mil-Spec can be a confusing term. What should people understand about Mil-Spec?

Chris Bartocci, Small Arms Solutions – Mil-Spec is revered as the Holy Grail, but that’s not true. Mil-Spec tells you the specifications and materials for every part and the drawing for every part. The primary reason for that is interchangeability. At Colt, for every lot of rifles, they would pull six rifles and take and disassemble them into bins. They would then build up six rifles pulling parts from each of those bins. They would then take two rifles and put them through endurance tests. So, one thing is Mil-Spec tells you that all parts are interchangeable.

In addition to interchangeability, you can tell what things like barrels will do and how long they will last. For instance, I can tell you exactly where an M4A1 SOCOM barrel will fail in a destruction test within a magazine or two. We know precisely what they will take as far as endurance.

It also focuses on materials. Everybody manufacturing for the U.S. Government has to verify their materials to ensure everything is proper. It’s a minimum standard that something has to be accepted into U.S. Government inventory. Are there ARs out there that exceed that? Oh, absolutely. So it is basically a minimum standard, but Mil-Spec ensures parts compatibility, the life cycle of the equipment, and the materials. It also ensures that, during the testing phase, every lot has a sample taken from it that passes reliability and durability testing.

When it comes to Mil-Spec, your readers might wonder who has that. Colt has that. They are the only ones that have the TDP. Now, other companies can achieve the same if they manufacture the major components in-house. An example of that would be LMT, for example. They manufacture their bolts and bolt carriers in-house to completely control the major components that fit together. They have complete control over it, and they know they are going to work reliably together.

There are a few other companies that manufacture in-house. Sig is one of them. But most companies that are out there are assemblers. So, you are relying on the idea that as parts come in, they check the dimensions with their drawings, or when they put their guns together, they do enough test firing to ensure that everything is working correctly.

Q: You’ll sometimes hear that someone is misusing the term “Mil-Spec.” What would that mean exactly?

Chris Bartocci, Small Arms Solutions – Anyone can do certain aspects of Mil-Spec, like “Mil-Spec Hard Coat Anodizing.” There are certain parts that are Mil-Spec that you can duplicate with testing. There are certain configurations that could meet somewhat Mil-Spec. If that makes sense, you might look at Mil-Spec as a configuration instead of a process. For example, if you look at a “Mil-Spec M4,” it has a round handguard and an M4 profile barrel, etc.

Q: That’s what’s sometimes confused me. The idea that someone is referring to a configuration…

That’s where a lot of the misconceptions come in. People are looking at the rifle’s configuration. Really what it gets down to is the production of the guns…how they are made, what they are made of, the quality control that has to go into them.

Many companies don’t like doing military work. The reason is they don’t like the fact that they are going to have a U.S. Government inspector having an office in their facility who is going to be monitoring everything they do to ensure they maintain Mil-Spec. They have to keep records of materials, inspections, etc. Many companies don’t have that oversight, whereas companies like Colt and FN have a permanent presence within their facilities. Also, consider that if a problem or critical failure is found during inspection or test firing, the entire lot is inspected. That can get very expensive.

Q: So, are there companies that have impressed you during your work that people should take a closer look at?

Chris Bartocci, Small Arms Solutions – Everybody who knows me knows there is a specific manufacturer that I have a preference for. It’s one that I have done work for in the past. Due to that work, I know their quality control, and it impressed me. I’ve not worked for them in some time, but I have to say that I am an LMT or Lewis Machine and Tool fan. I think what Karl Lewis has done with the AR platform is fantastic, and I consider the LMT MRP to be the fourth generation of the modern M16.

It was the next level after the M4 as far as modularity. The stuff he does on his rifles as far production spares no expense. His barrels are of excellent quality. His Enhanced Bolt Carrier Group is one of the best enhancements you can put in an AR, and in my opinion, it is the best bolt in the industry.

Q: I have seen more than a few guys seek out an LMT bolt to put into something like a more standard Toolcraft or perhaps Microbest Bolt Carrier Group. Researching that for one of my recent rifles, I learned that bolt is expensive and somewhat hard to track down. Can you share a brief history and why it is sought after?

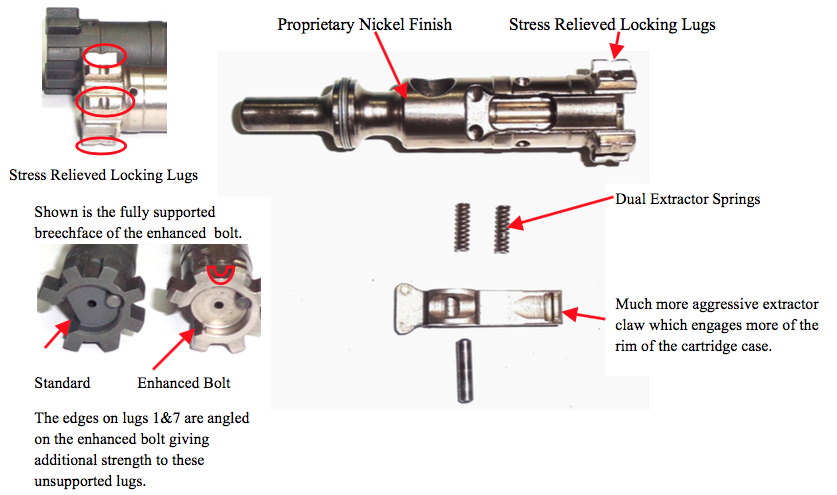

Chris Bartocci, Small Arms Solutions – It’s a bolt that came out of a request from SOCOM. Early in the War on Terror, Colts had an issue where bolts were breaking. The bolts were breaking at low round counts. Locking lugs were shearing off; there were failures to extract. In all fairness to Colt, they were having some QC issues then. Karl Lewis decided to look at the entire bolt carrier group and the problems the M4 was having and then designed the entire system around the M4. A carbine has a different operating dynamic than a rifle. You have a shorter gas system and higher residual pressures when the bolt is starting to unlock…the extractor has to work much harder to pull that cartridge case out of the chamber.

He designed his bolt carrier with a modified cam track, which increased the time the bolt was closed, allowing more time for the cartridge case to contract back down for easier extraction. He also changed a bit about how the gas was brought into the carrier. Instead of having one hole that dumps the gas straight down, he put in two chambers that separated it. He also added a gas exhaust port to bleed off unneeded gas quicker, which allowed for slightly slower operation.

For the bolt, he redesigned everything. The first issue he looked at was its strength. He came out with a proprietary material vastly superior to Carpenter 158. He looked at issues with over-the-beach ruptures of the bolt. He then focused on the extractor. He used two springs instead of one to make it much stronger. He also made the extractor much more durable. Then he looked at the locking lugs, modifying their dimensions, evening loads, and eliminating weak spots. He also put a cut on the locking lug, which acts as stress relief. On top of that, he put a durable, nickel-type finish on it.

Basically, he introduced a bolt carrier to address all of Colt’s problems. However, it was found that it didn’t work properly in M16A2 and A4s. The reason was you had a very different operating dynamic with a full-length gas system, and it caused issues with bolt carrier bounce on auto. It worked fine semi-auto, but on auto, it didn’t. Secondarily, Colt got its act together. They discovered their problems, corrected heat-treating issues, and the situation became less and less.

That said, what LMT had created could never be matched by a Mil-Spec bolt, even though the cost was double due to materials, cutting that material, etc. So, the LMT bolt never really saw the prime time. Today though, I must say that the LMT bolt is a vast improvement. I can’t think of a better enhancement you can do, as it is the heart and soul. Today, many of the guns that LMT sold for their New Zealand contract, their special forces rifle use features that bolt carrier group. Many of the guns they have sold to special forces overseas also use that bolt carrier group.

Q: Any other companies that stand out to you right now?

LWRCi makes beautiful external piston guns. For those that like the short-stroke operating system, I am a big fan of Primary Weapons Systems. Caracal is a company that many people still don’t know enough about.

If you’re looking for a gun that is an absolute beauty, Radian is one of my favorites. I feel like they work with aluminum like Picasso did with paint. Another really good one is San Tan Tactical. Their complete rifles and their receivers feature some excellent manufacturing. In the end, I think there are many good companies out there. Now, you can spend 500 dollars or 3 or 4,000 dollars. My advice today is that if you spend somewhere in the middle, you will get a very nice rifle.

###