We recently reached out to Chad Albrecht at School of the American Rifle to discuss common misconceptions about AR headspace gauges, and confusion about various AR-specific headspace gauges on the market.

We’re beyond thrilled to have Chad as a resource to be able to ask occasional questions to…To learn more about him and his School of the American rifle, please be sure to check out our feature interview with him…or other more recent articles which you can find here:

- Common AR-15 Myths – School of the American Rifle

- AR-15 Gas System Issues – School of the American Rifle

Q: Can you tell our readers why you feel it is important that builders check and gauge their ARs headspace?

Chad Albrecht, School of the American Rifle – There are lots of areas on the gun that we can gauge, but probably the most consistent part that I see that’s off if you actually do gauge it, that is critical to function, is headspace…

Q: Perhaps you could walk us through a very high level explanation of what headspace is…for someone who is maybe building their first AR?

Chad Albrecht, School of the American Rifle – Essentially what it comes down to is there is a necked-down portion of the chamber, and there is a portion that they call the datum line, and that’s where a measurement takes place…from that portion of the taper to the bolt face.

Once the bolt is closed and completely locked up, it is the distance from that bolt face to that particular part of the taper. It is a distance that is either a “go”, a “no-go” or a “field”.

This headspace gauge terminology tends to hang people up, but essentially you always want the chamber for the caliber you are shooting to close on the “go.” That means that it is at least long enough for it to chamber factory ammunition that is loaded to SAAMI specifications.

Q: So, this isn’t necessarily applicable for hand-loaded ammo?

Chad Albrecht, School of the American Rifle – If you’re into reloading, a lot of that can go out the door, depending on how somebody is loading that ammunition…but if it is factory ammunition you are buying from the store, it should chamber in a gun that closes on a “go” gauge. If it closes on that “go”, it’s not going to be mashing the bolt closed to crush a factory round into the chamber, which is one of the problems that I run into the most consistently.

Q: I know more than a few builders who simply check headspace by testing with their ammo…can you explain why that’s not an optimal approach?

Chad Albrecht, School of the American Rifle – People are like “well, I never check headspace. I just put a live round in there and if it closes and fires, I know that it’s good.” So, what will happen then is it will basically mash the brass because it is soft…assuming that it is not super short.

It will mash it in there, and in some cases, the person will never notice that there is a problem. But if you examine the brass, or if you have trouble opening the bolt after chambering a round, those things will tell you something is going on.

If headspace is short, the back of the brass will indicate it is having trouble getting out of the chamber. That’s because it is basically creating a higher chamber pressure when it is collapsing the case.

Alternatively, you’ll find it’s harder to extract the round because it is jammed in there, and the extractor is trying to fight it out if you are manually extracting a live round.

Differences in Calibers

For the most part with the AR, there’s not a lot of difference in gauges from caliber to caliber, unless you are dealing with NATO ammunition. There’s a big difference, especially with .308 versus 7.62 NATO when it comes to headspace specifications. It changes from gun to gun, depending on what weapon we are talking about.

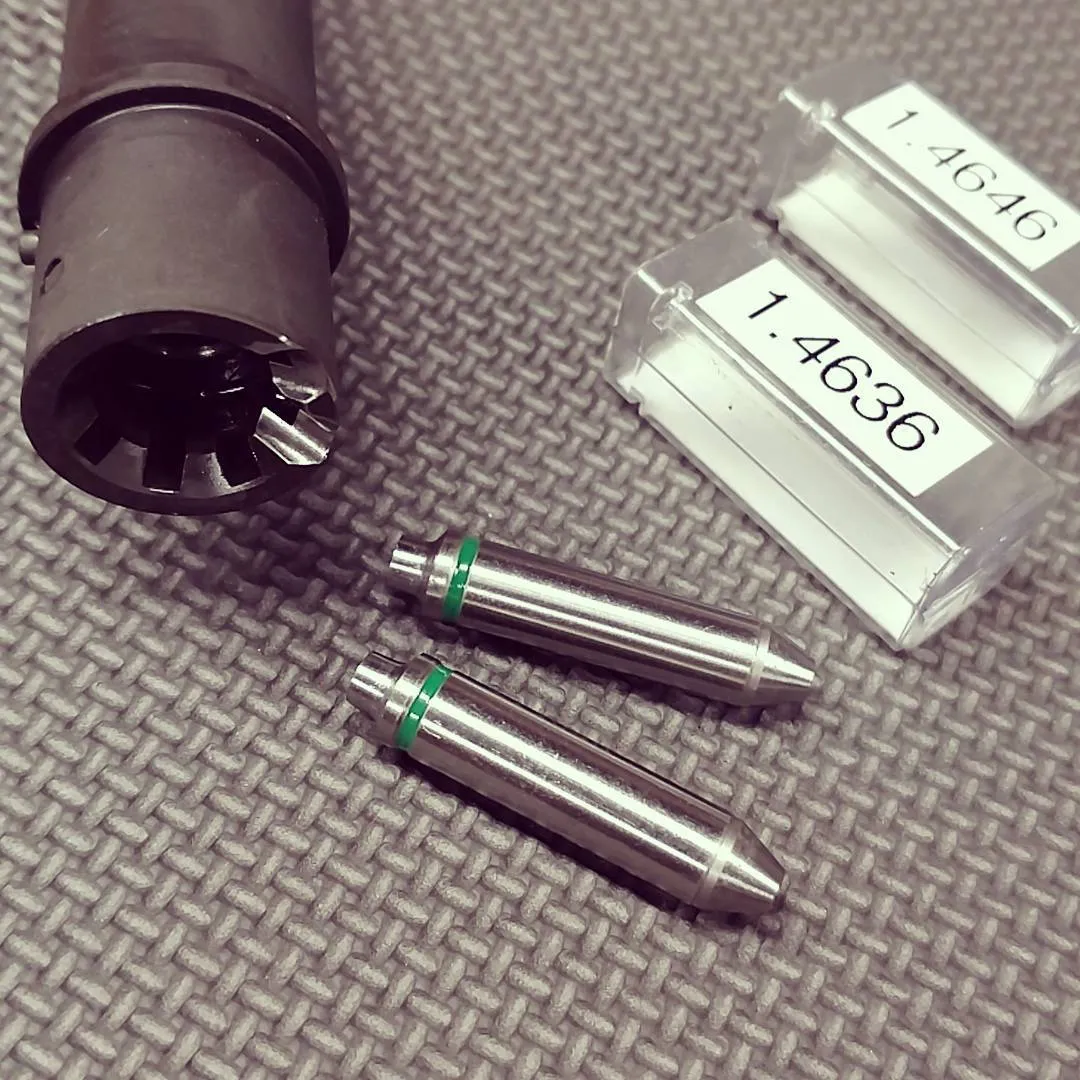

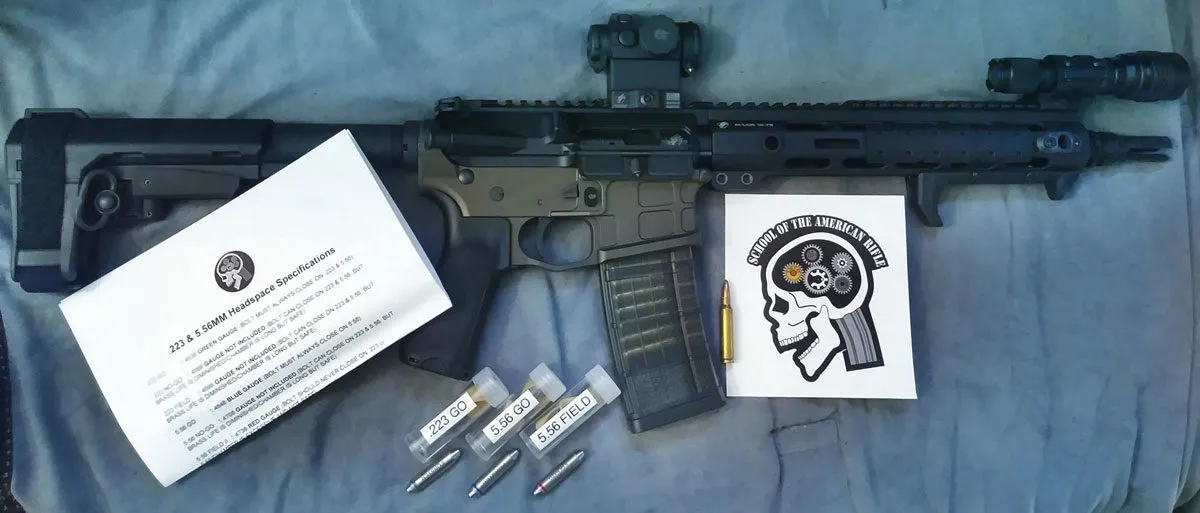

The same thing applies to .223 and 5.56, and that’s probably the most commonly misunderstood…even some of the headspace gauge manufacturers get it wrong. For instance, I use Forster gauges, but Forster makes a .223 headspace gauge that is listed as 1.4636. They then make another gauge that is listed as 1.4646, which is a special purpose gauge if you look it up at Brownells…

The Proper “Go” Dimension for 5.56

The 1.4646 is actually the proper “go” dimension for a 5.56 chamber. That’s what Colt uses, and that’s what a lot of other manufacturers that tend not to discuss it use, as well.

Most places that you call, if you ask, they’ll simply tell you that they use “the 5.56 spec.” The problem is most companies, if you look at the gauge, it will say “5.56 NATO” on it and they are actually using the 1.4636 spec, which is closer to the SAAMI specification for .223.

So, what happens is you have a lot of manufacturers listing a barrel marked as “5.56”, but will only close on the 1.4636 shorter .223 go-gauge. So, when you get into the higher pressure 5.56 round, or you get into where the throat in front of the headspace area is a little shorter, all those things can increase chamber pressure. That can cause the gun to either have poor accuracy, not chamber rounds reliably because its too short, or have extraction problems…

Q: You work with a LOT of ARs…just how common are these sorts of headspace issues?

Chad Albrecht, School of the American Rifle – It’s one of the biggest issues I see. Let’s say I have a class of 16 students, and each student brings three 5.56 marked upper receivers…20 percent of them won’t close on the 1.4646 gauge. Probably 10 percent of them won’t even close on the 1.4636 gauge.

Q: In your classes, is this mostly an issue with guns that are built vs. factory rifles?

Chad Albrecht, School of the American Rifle – Some of these are factory guns that left the factory that way, and some of them were ones that people were putting together…That’s where you can get some tolerance stacking that can come into play. But it’s really mind-boggling when you look at it that all these guns have these issues when you break out gauges and start checking them.

Q: You’re quite vocal about gauging….I imagine you get pushback from folks about the need to check headspace?

People assume that “an AR does not need to be headspaced because the barrel extention controls the head space on it” and then they go into arguing about the reasons for not using it…and in most cases when I actually talk to those people and I ask “do you have gauges?” 95 out of 100 of them will say “no, I don’t.” My next question then is “How do you know? You’re saying they’re not needed and you have not used them and don’t own them…how can you quantify that?”

Q: Some readers out there might see the “headspace” headline and think “this all sounds a bit technical…this is not for me.” What would you say to that person?

Chad Albrecht, School of the American Rifle – I’d say “What is the worst-case scenario?” I’d say if there are a multitude of issues going on with that gun…not just head space being short, but let’s say the firing pin protrusion is too long…the AR shouldn’t fire out of battery. That means the bolt, until it’s locked up all the way, the firing pin does not stick out far enough to cause the gun to go off if the bolt isn’t locked up.

BUT, lets say you have a gun that has a very short chamber, and the firing pin protrusion is really excessive…because you never checked it. You assumed that it was right.

So, if that gun goes to lock up, and it’s not completely locked up, let’s say it’s 80% locked up, and then you pull the trigger and the bolt is not closed all the way, it will blow up. You will find yourself having a 50-60,000 PSI bomb going off in front of your face, ten inches away.

Q: Could you also have an issue if you had a primer that was not fully seated?

Chad Albrecht, School of the American Rifle – You could. Let’s say you have reloaded ammunition and maybe when you reloaded it, the primers were not really pushed in well and they’re sort of floating…so, they can back out.

Now, imagine everything being mashed together because everything’s too tight. You can set something off. The AR has a floating firing pin, so it could always come forward with a little bit of force. So, all these variables when it’s trying to crunch something into the chamber is less than optimal.

Headspace Gauging and Temperature

Also, headspace is something that is always gauged at room temperature. So, if you get the weapon hot, things do change a little bit…and that’s what the gauges do take into play.

As long as a gun gauges out o.k., you will be fine…but if you have a gun that already has short head space when it’s cold, you get the gun really hot and you just keep on hammering rounds through it, then it can cause that short head space to amplify. As things get fouled, then everything gets even tighter.

Q: So, when exactly should we be checking headspace? Right after we build the gun? When we swap out certain parts? How does that work?

Chad Albrecht, School of the American Rifle – It depends on how seriously your readers take this, but normally my rule is any time I am building a new gun, any time I am changing a new barrel, or any time I am putting a new bolt in it.

Basically, any time I am changing a bolt or a barrel on an AR, I am always checking it to make sure it closes on the “go”…and from there I use other gauges to make sure it is not excessive or sloppy.

Q: Anything else we need to be aware of?

Chad Albrecht, School of the American Rifle – From there, the next thing would just be the confusion with the different types of gauges. As I mentioned, you have a “go”, a “no-go” or a “field”. Those three things are sort of thrown around interchangeably when it comes to “no-go” and “field.”

Two Piece Gauge Set…

The way I explain it to people is if a company produces a two-piece gauge set…I have a 6.8 gauge set in front of me right now from Manson. They may only make a “go” or a “no-go”, they don’t have a “field”.

If that’s the case, and the company only sells a “go” or a “no-go”, you want it to always close on the “go”…never close on the” no-go.” A “no-go” is equal to a “field” because it’s only sold in a two-piece set.

Vs. a Three Piece Gauge Set

But, let’s say you buy 300 Blackout gauges from Pacific Tool & Gauge and they have three pieces – a “go”, a “no-go” and a “field”. It should always close on the “go.” If it closes on the “no-go” it’s not unsafe, it just means that the chamber is sort of sloppy and a little bit long.

If it closes on the “field” then it’s unsafe to fire, because it’s too long…it means that the casing can stretch too much, rupture and it doesn’t contain the gasses like it’s supposed to.

So, people get confused about that. They’ll say “you need to have a go and a no-go,” but what it comes down to is who makes the gauges and what quantity do they make them? Do they make them in a three-piece set or a two piece set? That’s where people get confused.

They’ll buy a “no-go” headspace gauge and the gun eats it up, and they’ll go “oh my goodness, my gun is unsafe, it’s going to explode.” We’ll it depends on if that manufacturer made that “no-go” gauge equal to a “field” or if it’s just indicating that the chamber is a little sloppy.

###

2 - 2Shares

I’ll just say that while I didn’t see it mentioned, I put a new barrel on an AR that worked fine before, had maybe 1500 rounds through it as-factory, no issues. Started with some handloads at the minimum load spec, and noticed the primer was beyond flat (flowing actually), the case head was showing imprint from the bolt face, and to boot, the case separated. Re-visiting, making sure I did not make any errors with the charge weight or powder used, I shot again, and the case showed the same symptoms, with a crack where the case started to separate.… Read more »

I am looking for 5.56 headspace gauges that do not require the ejector to be removed.

I know someone who has a collection of inexpensive AR-15/10s from manufacturers such as Armalite, Savage, Diamondback, Delton, and Ruger with an LCWRI on order. He would like to start to try improving/insuring the reliability of some these rifles by upgrading the bolts and bold carrier groups. First he wishes to purchase a set of headspace gauges. My question is: for his first set of headspace gauges, should he purchase 5.56 or 223 gauges? He is leaning towards 5.56 as the weapons are all 223 Wyse (sp?) or 5.56. Also do you recommend a brand if Forster is not available?… Read more »

So What size gages should be used with 223 wyld Brownell says use 5.56 gage set , would that be right ?

Can these rimless headspace gauges be purchased? Also, do they also clear the ejector? Thanks.