We recently touched base with Monty LeClair of Centurion Arms to see what was new since we last spoke to him about his company and his experiences with the MK12. You can read that article here.

In this article, we discuss Monty’s recent push to take production in-house, what he feels makes his cold hammer forged barrels superior to many others on the market and why he feels some companies simply use the “cold hammer forged” as a marketing term. We also talk custom gas ports, and his company’s unique approach to gas blocks, and ideas for future chamberings.

Q: Monty, can you give our readers a quick refresh on your background and what you’ve been up to at Centurion Arms over the past several months?

Monty LeClair, Centurion Arms – My background is that I am a retired SEAL and I have had a lot of actual hands-on use with the weapons, and later on in my career I ended up doing a lot of developmental stuff working for WARCOM and SOCOM. I got to see a lot of different weapons programs just being a “gun guy” myself. I’ve continued to do gun stuff after I have gotten out. I had the business going beforehand but I’ve continued down that road.

More recently, we have gone ahead and expanded more of our hammer-forged barrels. We now have the 10.3″ with the proper MK18 SOCOM spec’d gas port in it. We have done some 11.5” with the proper FBI-spec’d gas ports. Then we had the 12.5” that we had before that were really popular with guys who were running them suppressed…

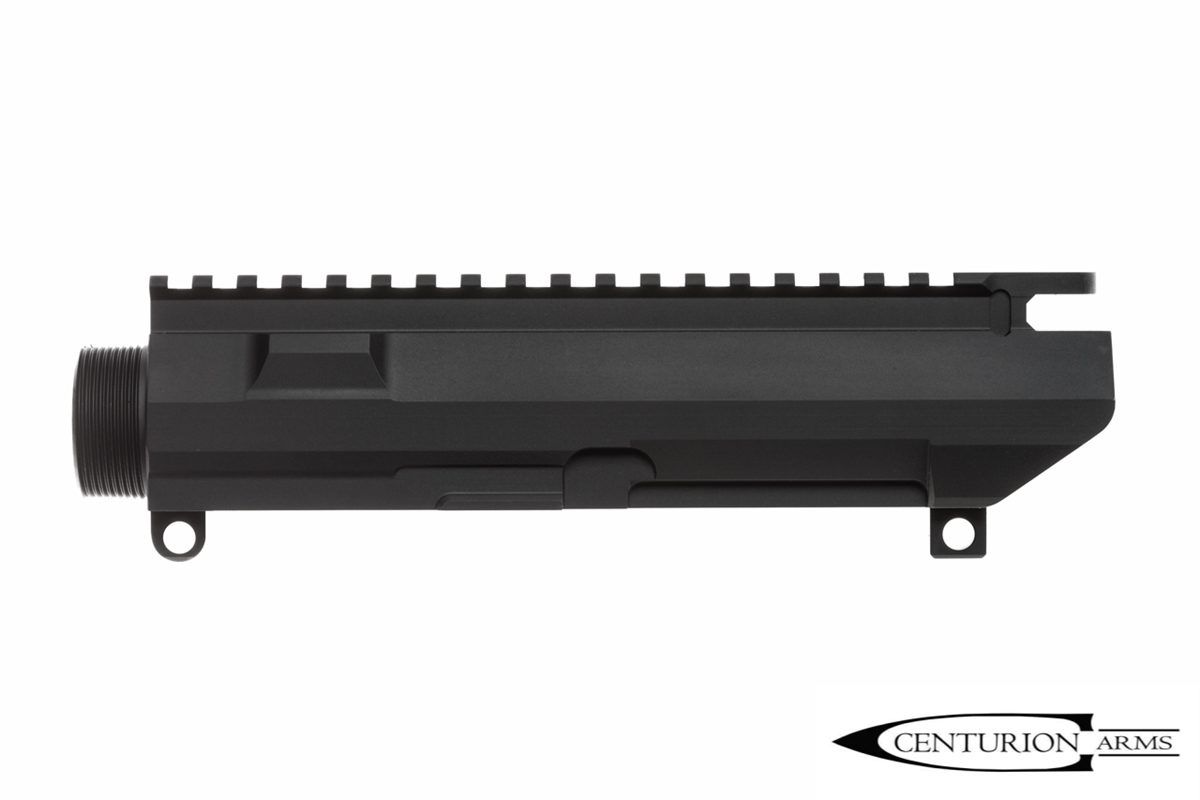

We have the billet upper and lower for 5.56 and 7.62, and those are doing really well. We’re also doing complete rifles. We’ve gotten those up and running since the last time I talked to you. Those are going really well also.

“Everything we do simply works”

Basically we just source the best components we can, or we can hold to tolerances that we know are going to work very well. We just want to make sure that everything we do simply works.

To me, I view the weapons I make as life-saving equipment. I want to treat them as such and because of that, I have a duty at Centurion Arms to make absolutely the best products that I possibly can.

I think this mentality is more important than ever. I say that because as I shopped around recently for vendors for items that I was not going to make myself in-house, I just saw a huge disparity in quality with what’s out there.

Don’t Be Fooled By Outside Appearances

It’s been shocking for me to see how a few small dimensions that are off in one place can make such a huge difference. I’ll find a product does not work but just as far as appearance, it looks to be completely identical to an actual quality item that runs flawlessly.

So, as I’ve continued down the road of manufacturing and sourcing things that Centurion Arms can tweak and can put our name on and do things with, I’ve just been working hard to make sure what I’m coming up with is actually the best quality stuff.

I’m committed to being up there with the best items on the market and doing the absolute best that I can for shooters and builders who demand things that work.

Q: Let’s talk about your Centurion Arms barrels and what makes them worth considering?

Monty LeClair, Centurion Arms – One example of a barrel we are doing in house at Centurion Arms is the precision barrel. I have a background as a sniper, and I have experience with the MK12. Well, I want to surpass that platform with capability and quality…To try to accomplish that, we’re doing 5R cut rifle barrels that are hand lapped…and we’re doing them in 7.62 and 6.5 Creedmoor as well.

Another thing we’re doing to be better and something that is overlooked by a vast majority of people when talking about precision weapons is timing the gas port to a groove. It’s something that we’re doing in an attempt to go above and beyond.

We looked around at other people doing barrels and it seemed like nobody wants to take the time to do that. Basically as a gas port erodes, you have less deformation or effect on a bullet by actually timing the gas port into a groove. So, it’s something that we’re doing to take the extra step to make solid, precision weapons.

Centurion Arms Hammer Forged 5.56 Mid-Length Barrel – 16″

Q: I’ve heard Centurion Arms does custom gas ports? Can you talk about that briefly?

Monty LeClair, Centurion Arms – For the 7.62 stuff, we are going to turn most of all of that stuff in house at Centurion Arms now. We’ll be able to time gas ports and do custom gas ports to whatever size is needed. We’re drilling from scratch.

With a lot of the other barrels, as we’re going, we are probably going to do an initial gas port undersized…we’ll have a standard one that we sell for reliability with a larger variety of ammo. But, if guys have special requests or specific requirements, we’ll be able to do that as well with a lot of the barrels…definitely with the Centurion Arms precision barrels.

Q: Can you explain to a newer builder why someone might want a custom gas port?

Monty LeClair, Centurion Arms – With a lot of the ports out on the market now, companies are trying to compensate for not knowing what the customer is going to do. They actually quote/unquote “over gas” the gun for some ammo to make sure that it will still function and operate with the low quality stuff. That way, they do not have to deal with a bunch of customer service stuff when people are shooting poor ammo.

However, if we have a customer who understands the weapon platform, its ammunition and how it functions as a system and they are going to shoot a consistent diet of high quality ammo or reloads or a very specific brand…what they can do is they can get a gas port that is tailored to that ammo so they are not over gassing their gun.

Smooth and Reliable

Also, if someone is going to be shooting a specific load with a suppressor, which is going to add more back-pressure, they can downsize their gas port, which, as long as they stick to the ammo diet that they are planning on for their rifle, it’s going to be just as reliable.

It’s not going to over gas the gun, and it’s not going to beat it up…nor is it going to cause potential reliability issues down the road with wear on parts due to over-stressing the system, or having the system “outrun itself” so to speak. It will allow you to tune your buffers with it and basically have the smoothest operating system you can have with the ammo that you’ve chosen without losing any reliability.

Q: What makes Centurion Arms hammer forged barrels unique in your view?

Monty LeClair, Centurion Arms – Centurion Arms was one of the first companies in the game for the hammer forged barrels early on. During that time frame, I was doing a lot of traveling, and I had been to Belgium at FN and at the U.S. plant doing a lot of weapons development. There, I got to see a lot of stuff, and I was able to talk to a lot the engineers. Also, I got a good understanding of the material that they were using to get enhanced performance…I saw how they had a tapered bore in the last portion of the barrel.

They did little things like that to help overcome some of the issues with inconsistencies in chrome while still maintaining accuracy. I saw how they were basically just stacking the elements of the manufacturing process in their favor for a higher quality barrel as far as longevity and accuracy.

“Cold Hammer Forged” as a Marketing Tool?

With that information, I now spec that stuff into what we are doing at Centurion Arms. I know that later on as the hammer forged market expanded; the vast majority of companies are not doing that. They’re just going in and saying “hey, just get me a cold hammer forged barrel.”

I also know the vast majority of companies not looking at the other things like the tapered bore. They’re not looking into the material specs for what they call “machine gun steel”. They’re using standard 4150 CMV as opposed to some of the more durable materials out there.

The hammer forging process to them is just a marketing tool as opposed to something they are using to actually improve the performance of barrel.

Centurion Arms Hammer Forged 5.56 Mid-Length Barrel – 14.5″

Q: Anything else on barrels you want to mention?

Monty LeClair, Centurion Arms – One of the things we are getting into on all of our Centurion Arms barrels is we are putting in something called “keyed gas blocks.” We put the gas port in, and we put a little receptacle, for the lack of a better word a “female” portion in the barrel, and the gas blocks, as we’re machining them, have a tab on them and they slide in there.

It makes it where you cannot misalign or have a canted gas block. Even if there is a minor bit of play, we have it spec’d so that it is tight enough to where it cannot cause issues.

In general terms, even if you have a gas block on crooked, you’re going to get enough gas. That’s because the gas port size of the gas block is large enough to encompass it. The unforeseen part of it where people start running into problems is if they cant it enough that it starts to cause a bind on the gas tube as it goes through the upper receiver into the carrier. After a while…it can cause problems.

Centurion Arms – Reliability and Aesthetics

With the tabbed gas block, we pin it. However, we’ll also be doing versions with set screws for guys that are building after the fact so if you’re using our gas blocks with our barrels, it makes it a no brainer. It takes out some of the elements that can cause reliability issues, as well as just aesthetically, making sure the gas block is on there properly. Once it’s seated and placed, you know that it’s good-to-go.

Q: How have you been able to bring so much in-house at Centurion Arms?

Monty LeClair, Centurion Arms – Centurion Arms had some newer machines for a while that we were not running full-time. That’s now not the case.

Currently, instead of running one shift all the time, we’re running two shifts to keep up with production, dealing with overseas military contracting stuff, OEM stuff for other companies, and overseas military contract OEM parts for other companies as well.

We’re also doing a lot of law enforcements…Heck, today I think I just sent out 1,000 rails for law enforcement.

Q: Just curious, what’s your opinion on calibers these days?

Monty LeClair, Centurion Arms – I think for generalized carbine stuff, the 5.56 is fine. As for the larger frame offerings, I am starting to explore 6.5 Creedmoor a lot more. I think it’s going to be a standard offering for me. I certainly think it’s a good cartridge and I want to focus on it.

It’s funny you ask this question. That’s because I’ve been thinking a lot about pushing the small frame platform harder than you can with 5.56…I’m going to start playing with other cartridges and calibers. I probably have four or five chamber reamers already in house. I plan on playing with them to see what I can do with the platform as a whole.

Centurion Arms – Looking at New Calibers

One is 6.5 Grendel, but realistically, I am probably looking at variations of the Grendel. There’s variations in .22 and 6mm and all sorts of other stuff. So, I’m probably looking at doing those as well.

I might even look at something for hunting. I do like to hunt on occasion and I’m going to try to get a chamber reamer for necking the 6.5 Grendel out to 30 cal. and using that as a hunting gun…and just seeing what kind of performance I can get out of it. I’ll just have to play with it and see.

Q: Finally, can we talk about Centurion Arms billet uppers and lowers?

Monty LeClair, Centurion Arms – Forging is good, and billet is good as well. Billet offers different aesthetics and you can program different stuff into it. Our plan is just having a good, tight fitting platform that we can actually handle all the dimensions on as far as being able to make the upper receivers a little tight for thermal fit and things like that.

It’s nice being able to control all that stuff in-house. We just want to make something a little bit different that is our own, as well to be able to make something that is nice when we’re doing our own complete Centurion Arms weapons.

Centurion Arms C4 5.56 Billet AR-15 Receiver Set

Q: This is not just small frame billet uppers and lowers, but large frame as well. Can you talk about those?

Monty LeClair, Centurion Arms – I’m glad you brought that up. What we’re going to roll with is going to be the Knight’s Armament pattern. There’s so much variety in the 7.62 platform, but really to us, after looking at everything, Knight’s Armament, if you can call any of them a mil-spec, I’d say they’re the only one with any significant service time in quantities.

As such, that’s what we want to make Centurion Arms stuff compatible with. We can basically sell uppers and lowers right now that are compatible with Knight’s Armament. We can interchange with that platform and I’ll also be able to build with some of their parts.

I’ll be able to add their rail for customers who want some custom stuff. Also, I’ll be able to use some of Knight’s Armament parts, and as we develop stuff, there should be some backwards compatibility as well, staying with that spec.

###

Special thanks to Monty LeClair for taking the time to chat with us. Also a big thank you to Matt Stonar and Jason Seehafer who assisted with the completion of this article.

Who’s manufacturing there barrels now?